Answered step by step

Verified Expert Solution

Question

1 Approved Answer

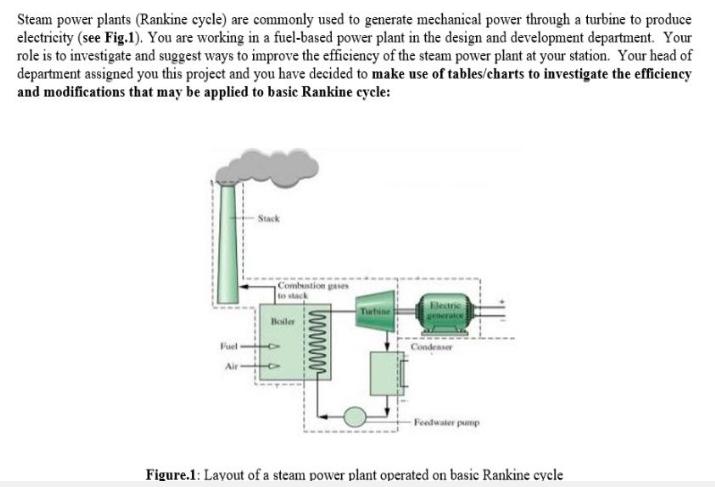

Steam power plants (Rankine cycle) are commonly used to generate mechanical power through a turbine to produce electricity (see Fig.1). You are working in

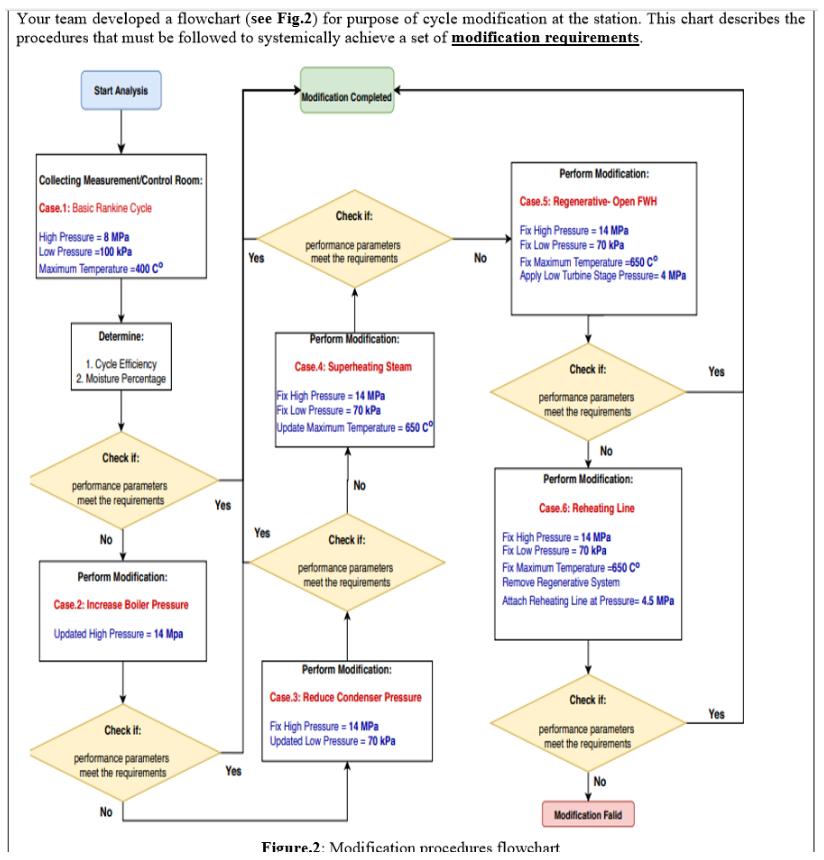

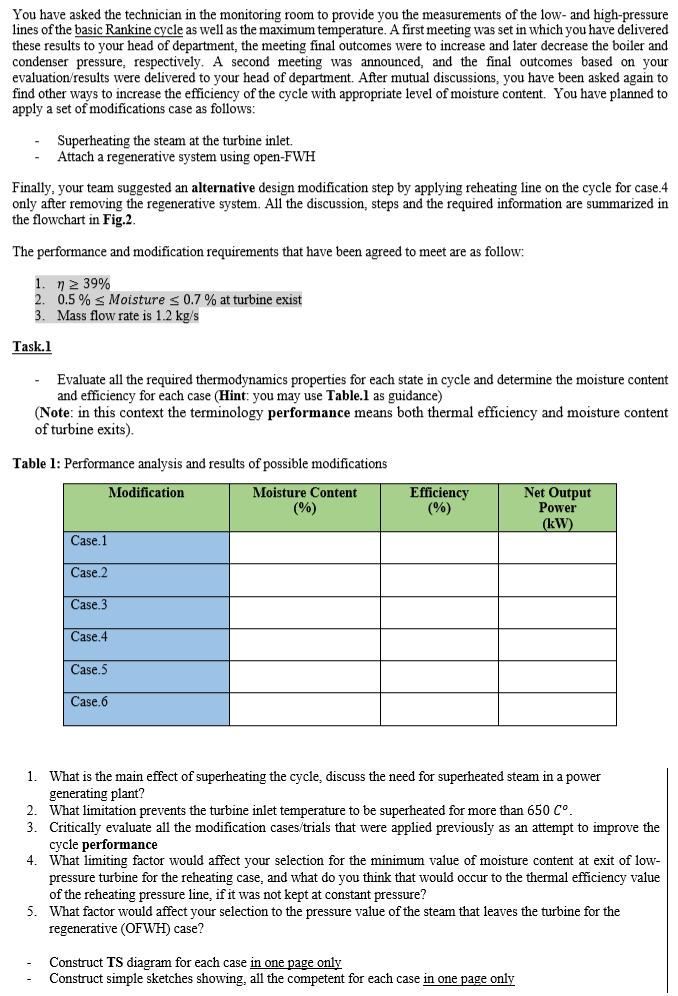

Steam power plants (Rankine cycle) are commonly used to generate mechanical power through a turbine to produce electricity (see Fig.1). You are working in a fuel-based power plant in the design and development department. Your role is to investigate and suggest ways to improve the efficiency of the steam power plant at your station. Your head of department assigned you this project and you have decided to make use of tables/charts to investigate the efficiency and modifications that may be applied to basic Rankine cycle: Air Stack Combustion gase to stack Boiler Beatri desser -Feedwater pump Figure.1: Layout of a steam power plant operated on basic Rankine cycle Your team developed a flowchart (see Fig.2) for purpose of cycle modification at the station. This chart describes the procedures that must be followed to systemically achieve a set of modification requirements. Start Analysis Collecting Measurement/Control Room: Case.1: Basic Rankine Cycle High Pressure-8 MPa Low Pressure=100 kPa Maximum Temperature -400 C Determine: 1. Cycle Efficiency 2. Moisture Percentage Check if: performance parameters meet the requirements No Perform Modification: Case 2: Increase Boiler Pressure Updated High Pressure = 14 Mpa Check if: performance parameters meet the requirements No Yes Yes Yes Yes Modification Completed Check it: performance parameters meet the requirements Perform Modification: Case. 4: Superheating Steam Fix High Pressure=14 MPa Fix Low Pressure = 70 kPa Update Maximum Temperature=650 Co No Check if: performance parameters meet the requirements Perform Modification: Case.3: Reduce Condenser Pressure Fix High Pressure = 14 MPa Updated Low Pressure = 70 kPa No Perform Modification: Case.5: Regenerative-Open FWH Fix High Pressure=14 MPa Fix Low Pressure = 70 kPa Fix Maximum Temperature=650 C Apply Low Turbine Stage Pressure- 4 MPa Check if: performance parameters meet the requirements No Perform Modification: Case.6: Reheating Line Fix High Pressure = 14 MPa Fix Low Pressure = 70 kPa Fix Maximum Temperature -650 C Remove Regenerative System Attach Reheating Line at Pressure= 4.5 MPa Check if: performance parameters meet the requirements No Modification Failid Figure.2: Modification procedures flowchart Yes Yes You have asked the technician in the monitoring room to provide you the measurements of the low- and high-pressure lines of the basic Rankine cycle as well as the maximum temperature. A first meeting was set in which you have delivered these results to your head of department, the meeting final outcomes were to increase and later decrease the boiler and condenser pressure, respectively. A second meeting was announced, and the final outcomes based on your evaluation/results were delivered to your head of department. After mutual discussions, you have been asked again to find other ways to increase the efficiency of the cycle with appropriate level of moisture content. You have planned to apply a set of modifications case as follows: Superheating the steam at the turbine inlet. Attach a regenerative system using open-FWH Finally, your team suggested an alternative design modification step by applying reheating line on the cycle for case.4 only after removing the regenerative system. All the discussion, steps and the required information are summarized in the flowchart in Fig.2. The performance and modification requirements that have been agreed to meet are as follow: 1. n 39% 2. 0.5% Moisture 0.7 % at turbine exist 3. Mass flow rate is 1.2 kg/s Task.1 Evaluate all the required thermodynamics properties for each state in cycle and determine the moisture content and efficiency for each case (Hint: you may use Table.1 as guidance) (Note: in this context the terminology performance means both thermal efficiency and moisture content of turbine exits). Table 1: Performance analysis and results of possible modifications Modification Moisture Content (%) Case. 1 Case.2 Case.3 Case.4 Case.5 Case.6 Efficiency (%) Net Output Power (kW) 1. What is the main effect of superheating the cycle, discuss the need for superheated steam in a power generating plant? 2. What limitation prevents the turbine inlet temperature to be superheated for more than 650 C. 3. Critically evaluate all the modification cases/trials that were applied previously as an attempt to improve the cycle performance 4. What limiting factor would affect your selection for the minimum value of moisture content at exit of low- pressure turbine for the reheating case, and what do you think that would occur to the thermal efficiency value of the reheating pressure line, if it was not kept at constant pressure? 5. What factor would affect your selection to the pressure value of the steam that leaves the turbine for the regenerative (OFWH) case? Construct TS diagram for each case in one page only Construct simple sketches showing, all the competent for each case in one page only

Step by Step Solution

★★★★★

3.42 Rating (165 Votes )

There are 3 Steps involved in it

Step: 1

ANSWER Task 1 To evaluate the required thermodynamics properties for each state in the cycle and determine the moisture content and efficiency for each case we will use the data provided in Table 1 an...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started