Answered step by step

Verified Expert Solution

Question

1 Approved Answer

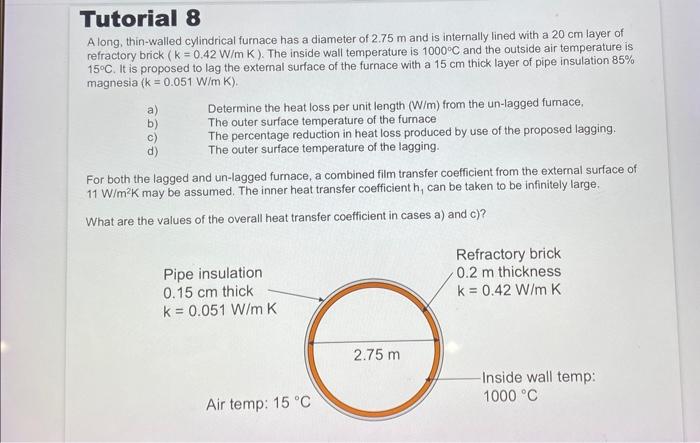

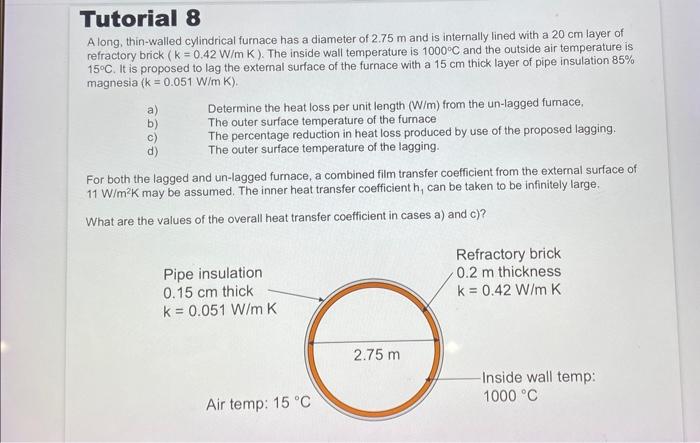

help A long, thin-walled cylindrical furnace has a diameter of 2.75m and is internally lined with a 20cm layer of refractory brick (k=0.42W/mK). The inside

help

A long, thin-walled cylindrical furnace has a diameter of 2.75m and is internally lined with a 20cm layer of refractory brick (k=0.42W/mK). The inside wall temperature is 1000C and the outside air temperature is 15C. It is proposed to lag the external surface of the furnace with a 15cm thick layer of pipe insulation 85% magnesia (k=0.051 W /mK). a) Determine the heat loss per unit length (W/m) from the un-lagged fumace, b) The outer surface temperature of the furnace c) The percentage reduction in heat loss produced by use of the proposed lagging. d) The outer surface temperature of the lagging. For both the lagged and un-lagged furnace, a combined film transfer coefficient from the external surface of 11W/m2K may be assumed. The inner heat transfer coefficient h1 can be taken to be infinitely large. What are the values of the overall heat transfer coefficient in cases a) and c)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started