Here I have attached the excel worksheets that goes with the questions

what do you mean networking?

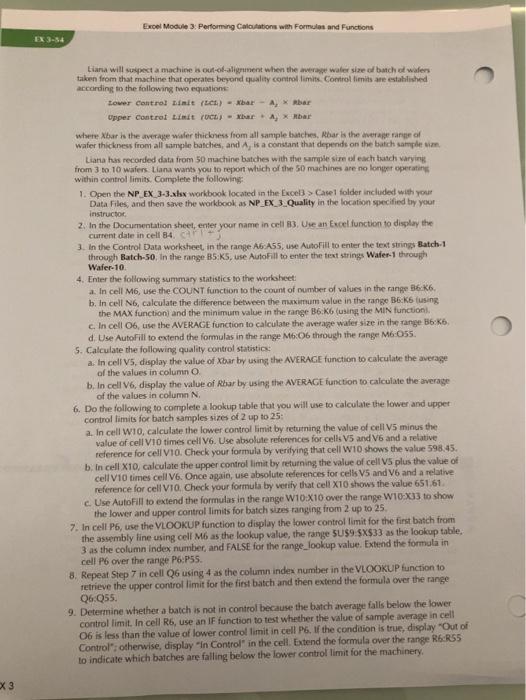

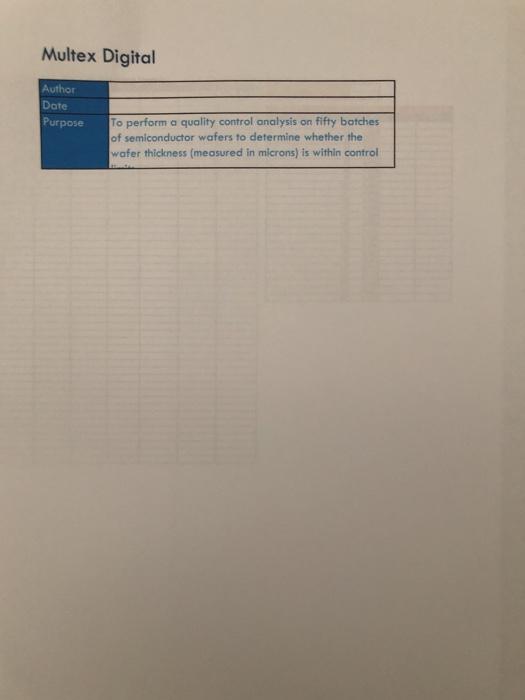

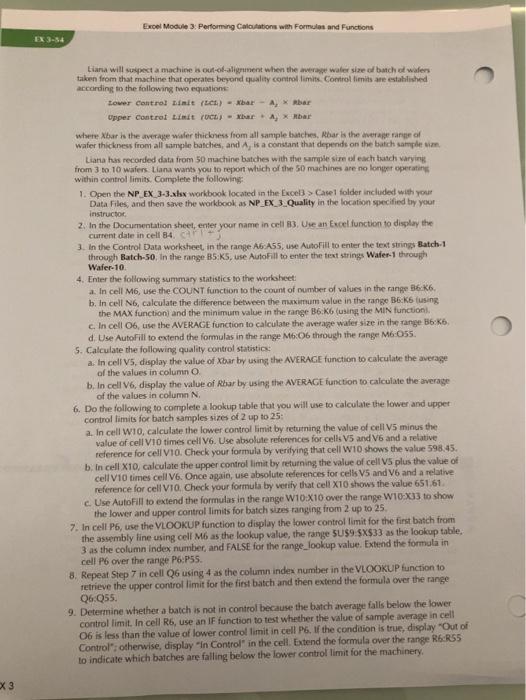

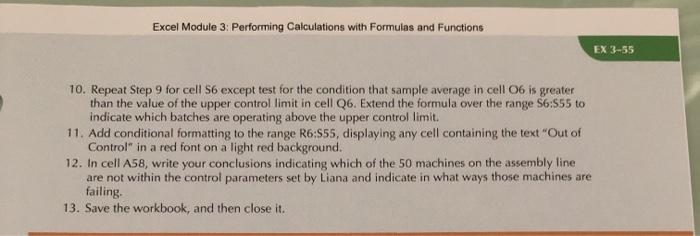

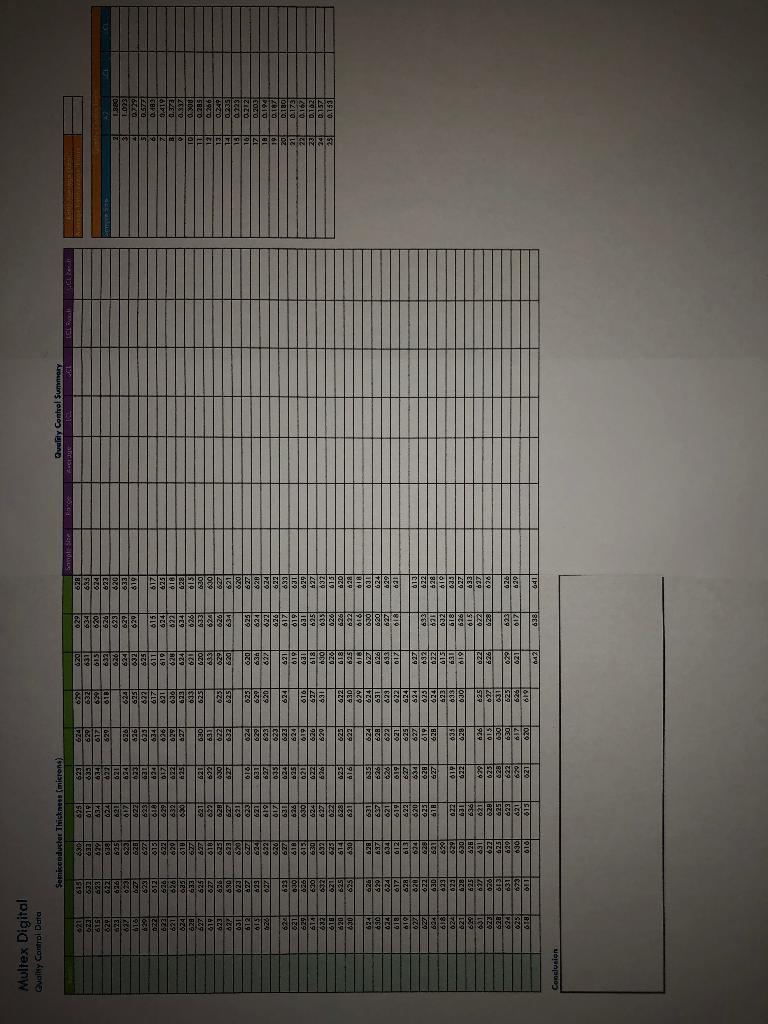

Excel Module 3. Performing Calculations wih Formulas and Functions EX 3-54 Liana will suspect a machine is out-of-alignment when the average wale size of batch of wafers taken from that machine that operates beyond quality controllimits. Controllimits are established according to the following two equatione tower Control Dimit (LCA) - Kar - A, bar Upper Control LINE TOCA - Xarx Mbar where bar is the average water thickness from all sample batches, Rhar is the average range of wafer thickness from all sample batches, and is a constant that depends on the batch sample Liana has recorded data from 50 machine batches with the same size of each batch varying from 3 to 10 wafers Liana wants you to report which of the 50 machines are no longer operating within control limits. Complete the following: 1. Open the NP EX 3-3.xlsx workbook located in the Excel) > Case folder included with your Data Files, and then save the workbook as NP_EX_Quality in the location specified by your instructor 2. In the Documentation sheet, enter your name in cell 83. Use an Excel function to display the current date in cell 34 3. In the Control Data worksheet in the range Ab A55, use AutoFill to enter the text strings Batch-1 through Batch-50, in the range B5 KS, use AutoFill to enter the text strings Water1 through Wafer-10 4. Enter the following summary statistics to the worksheet: a. In cell M6, use the COUNT function to the count of number of values in the range 36 K6. b. In cell N6, calculate the difference between the maximum value in the range B6K6 fusing the MAX function and the minimum value in the range 36.K6 (using the MIN function c. In cell 06, use the AVERAGE function to calculate the average wafer size in the range 36.6 d. Use Autofill to extend the formulas in the range MbO6 through the range M6-055. 5. Calculate the following quality control statistics: a. In cells, display the value of Xbar by using the AVERAGE function to calculate the average of the values in column b. In cell V6, display the value of Rbar by using the AVERAGE function to calculate the average of the values in column N 6. Do the following to complete a lookup table that you will use to calculate the lower and upper control limits for batch samples sizes of 2 up to 25: a. In cell wio, calculate the lower controllimit by returning the value of cell V5 minus the value of cell V10 times cell V6. Use absolute references for cells V5 and V6 and a relative reference for cell V10. Check your formula by verifying that cell W10 shows the value 598.45 b. In cell X10, calculate the upper controllimit by returning the value of cell VS plus the value of cell V10 times cell V6. Once again, use absolute references for cells V5 and V6 and a relative reference for cell VIO. Check your formula by verify that cell X10 shows the value 651.61 c. Use AutoFill to extend the formulas in the range W10:X10 over the range W10 X33 to show the lower and upper control limits for batch sizes ranging from 2 up to 25 7. In cell P6, use the VLOOKUP function to display the lower controllimit for the first batch from the assembly fine using cell M6 as the lookup value, the range 50$9:$X$33 as the lookup table, 3 as the column index number, and FALSE for the range_lookup value. Extend the formula in cell P over the range P6:P55. 8. Repeat Step 7 in cell Q6 using 4 as the column index number in the VLOOKUP function to retrieve the upper controllimit for the first batch and then extend the formula over the range Q6:Q55. 9. Determine whether a batch is not in control because the batch average falls below the lower controllimit. In cell R6, use an IF function to test whether the value of sample average in cell 06 is less than the value of lower controllimit in cell Ps. If the condition is true, display "Out of Control: otherwise, display in Control in the cell. Extend the formula over the range R6R55 to indicate which batches are falling below the lower controllimit for the machinery x 3 Excel Module 3: Performing Calculations with Formulas and Functions EX 3-55 10. Repeat Step 9 for cell S6 except test for the condition that sample average in cell 06 is greater than the value of the upper controllimit in cell 06. Extend the formula over the range 56:555 to indicate which batches are operating above the upper controllimit. 11. Add conditional formatting to the range R6:555, displaying any cell containing the text "Out of Control" in a red font on a light red background. 12. In cell A58, write your conclusions indicating which of the 50 machines on the assembly line are not within the control parameters set by Liana and indicate in what ways those machines are failing 13. Save the workbook, and then close it. Multex Digital Author Date Purpose To perform a quality control analysis on fifty batches of semiconductor wafers to determine whether the wafer thickness (measured in microns) is within control Multex Digital Quailty Control Data 1913 Excel Module 3. Performing Calculations wih Formulas and Functions EX 3-54 Liana will suspect a machine is out-of-alignment when the average wale size of batch of wafers taken from that machine that operates beyond quality controllimits. Controllimits are established according to the following two equatione tower Control Dimit (LCA) - Kar - A, bar Upper Control LINE TOCA - Xarx Mbar where bar is the average water thickness from all sample batches, Rhar is the average range of wafer thickness from all sample batches, and is a constant that depends on the batch sample Liana has recorded data from 50 machine batches with the same size of each batch varying from 3 to 10 wafers Liana wants you to report which of the 50 machines are no longer operating within control limits. Complete the following: 1. Open the NP EX 3-3.xlsx workbook located in the Excel) > Case folder included with your Data Files, and then save the workbook as NP_EX_Quality in the location specified by your instructor 2. In the Documentation sheet, enter your name in cell 83. Use an Excel function to display the current date in cell 34 3. In the Control Data worksheet in the range Ab A55, use AutoFill to enter the text strings Batch-1 through Batch-50, in the range B5 KS, use AutoFill to enter the text strings Water1 through Wafer-10 4. Enter the following summary statistics to the worksheet: a. In cell M6, use the COUNT function to the count of number of values in the range 36 K6. b. In cell N6, calculate the difference between the maximum value in the range B6K6 fusing the MAX function and the minimum value in the range 36.K6 (using the MIN function c. In cell 06, use the AVERAGE function to calculate the average wafer size in the range 36.6 d. Use Autofill to extend the formulas in the range MbO6 through the range M6-055. 5. Calculate the following quality control statistics: a. In cells, display the value of Xbar by using the AVERAGE function to calculate the average of the values in column b. In cell V6, display the value of Rbar by using the AVERAGE function to calculate the average of the values in column N 6. Do the following to complete a lookup table that you will use to calculate the lower and upper control limits for batch samples sizes of 2 up to 25: a. In cell wio, calculate the lower controllimit by returning the value of cell V5 minus the value of cell V10 times cell V6. Use absolute references for cells V5 and V6 and a relative reference for cell V10. Check your formula by verifying that cell W10 shows the value 598.45 b. In cell X10, calculate the upper controllimit by returning the value of cell VS plus the value of cell V10 times cell V6. Once again, use absolute references for cells V5 and V6 and a relative reference for cell VIO. Check your formula by verify that cell X10 shows the value 651.61 c. Use AutoFill to extend the formulas in the range W10:X10 over the range W10 X33 to show the lower and upper control limits for batch sizes ranging from 2 up to 25 7. In cell P6, use the VLOOKUP function to display the lower controllimit for the first batch from the assembly fine using cell M6 as the lookup value, the range 50$9:$X$33 as the lookup table, 3 as the column index number, and FALSE for the range_lookup value. Extend the formula in cell P over the range P6:P55. 8. Repeat Step 7 in cell Q6 using 4 as the column index number in the VLOOKUP function to retrieve the upper controllimit for the first batch and then extend the formula over the range Q6:Q55. 9. Determine whether a batch is not in control because the batch average falls below the lower controllimit. In cell R6, use an IF function to test whether the value of sample average in cell 06 is less than the value of lower controllimit in cell Ps. If the condition is true, display "Out of Control: otherwise, display in Control in the cell. Extend the formula over the range R6R55 to indicate which batches are falling below the lower controllimit for the machinery x 3 Excel Module 3: Performing Calculations with Formulas and Functions EX 3-55 10. Repeat Step 9 for cell S6 except test for the condition that sample average in cell 06 is greater than the value of the upper controllimit in cell 06. Extend the formula over the range 56:555 to indicate which batches are operating above the upper controllimit. 11. Add conditional formatting to the range R6:555, displaying any cell containing the text "Out of Control" in a red font on a light red background. 12. In cell A58, write your conclusions indicating which of the 50 machines on the assembly line are not within the control parameters set by Liana and indicate in what ways those machines are failing 13. Save the workbook, and then close it. Multex Digital Author Date Purpose To perform a quality control analysis on fifty batches of semiconductor wafers to determine whether the wafer thickness (measured in microns) is within control Multex Digital Quailty Control Data 1913