Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Holding cost $8/toolbox/month Month Demand Subcontract $80/toolbox July 400 Regular time $45/toolbox August 500 Regular time cost plus OT additional $20 per September 500

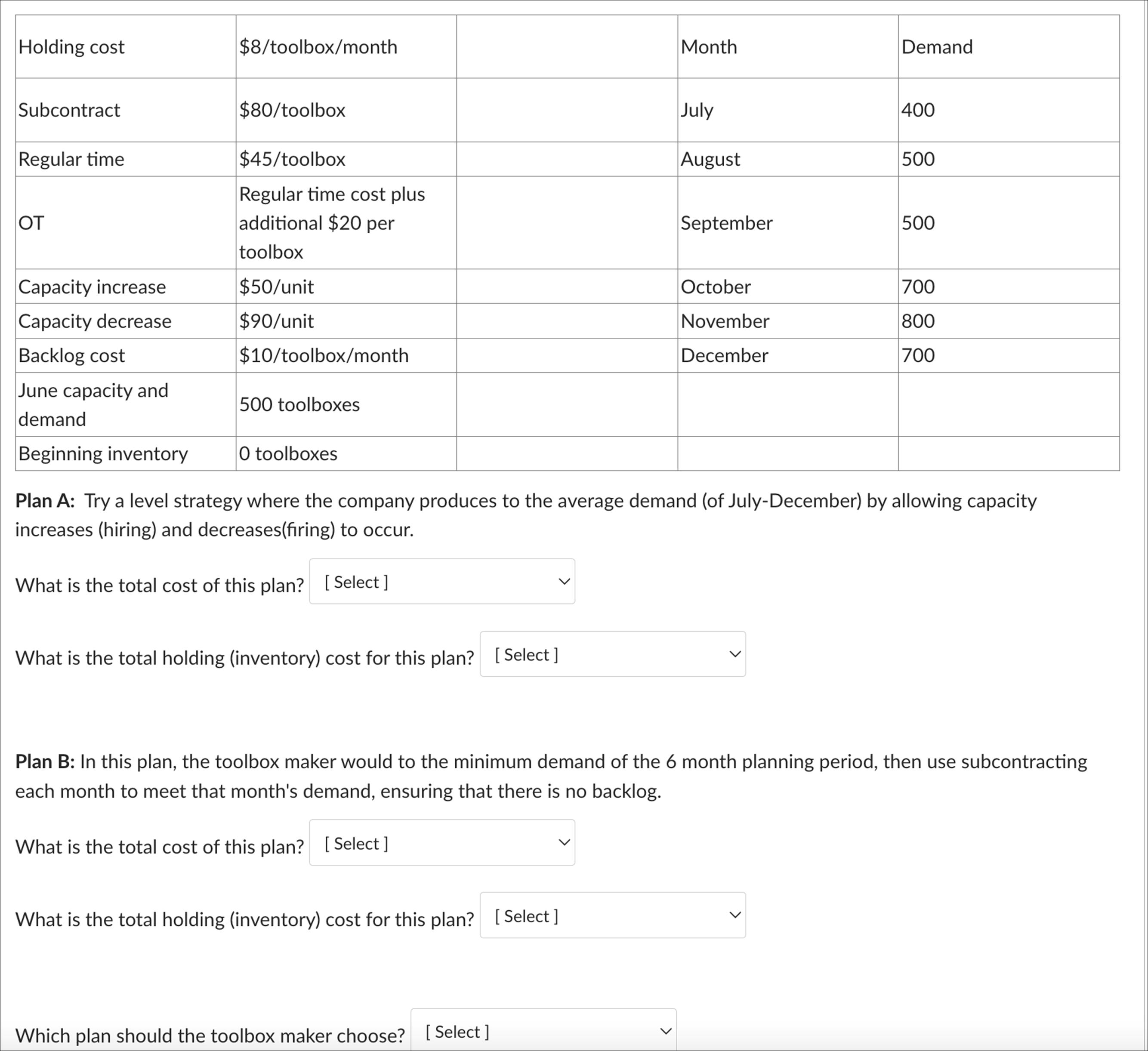

Holding cost $8/toolbox/month Month Demand Subcontract $80/toolbox July 400 Regular time $45/toolbox August 500 Regular time cost plus OT additional $20 per September 500 toolbox Capacity increase $50/unit Capacity decrease $90/unit Backlog cost $10/toolbox/month October 700 November 800 December 700 June capacity and demand 500 toolboxes Beginning inventory O toolboxes Plan A: Try a level strategy where the company produces to the average demand (of July-December) by allowing capacity increases (hiring) and decreases(firing) to occur. What is the total cost of this plan? [Select] What is the total holding (inventory) cost for this plan? [Select] > Plan B: In this plan, the toolbox maker would to the minimum demand of the 6 month planning period, then use subcontracting each month to meet that month's demand, ensuring that there is no backlog. What is the total cost of this plan? [Select] What is the total holding (inventory) cost for this plan? [Select] > Which plan should the toolbox maker choose? [Select] >

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started