Question

Homecamp manufactures home office equipment for remote work and is the leading provider of such equipment in North Europe for the B2B segment. With the

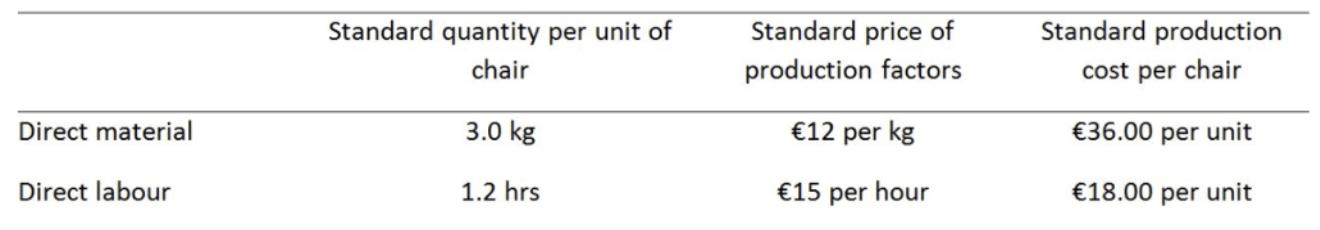

Homecamp manufactures home office equipment for remote work and is the leading provider of such equipment in North Europe for the B2B segment. With the pandemic crisis, remote work has developed a lot and practices have evolved with successive lockdowns occurring globally. Homecamp has refined its offer by proposing a line of ergonomic desk chairs usable indoors and outdoors. They are produced in one of Homecamp’s plants that we will call the ‘Ergo chair’ plant. Until now Homecamp desk chairs were not appropriate for outdoor use. This new line has required adjustment in the production process of chairs, including a new material with better resistance to light, humidity, and variation of temperature. The ‘Ergo chair’ plant uses a standard cost system and has established the following standards per unit of chair:

In April 20n, the plant recorded the following activity:

- The plant produced 6000 units of the desk chair, the same as budgeted. All units were sold.

- A total of 21 000 kg of material were used. Material purchases were invoiced at €241500 in total

- The plant employs 40 persons to work on the production of the chairs. These employees worked an average of 160 hours during the month, at an average rate of €16 per hour.

The director of the division is particularly interested in the performance brought by the new material. To support results analysis on this perspective, fill in the blank cells of the following table (Careful: only numerical value accepted, no text, 2 decimals expected at max)

![Flexible budget adjusted to actual yield Actual Budget (Réel) (Budget ajusté au rendement réel) 6000 [B] [G] 3[C] [H] Produc](https://dsd5zvtm8ll6.cloudfront.net/si.experts.images/questions/2022/02/62187ca37e60e_1645771933048.jpg)

Standard quantity per unit of Standard price of Standard production chair production factors cost per chair Direct material 3.0 kg 12 per kg 36.00 per unit Direct labour 1.2 hrs 15 per hour 18.00 per unit

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Flexible budget adjusted to actual yield Budget Act...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started