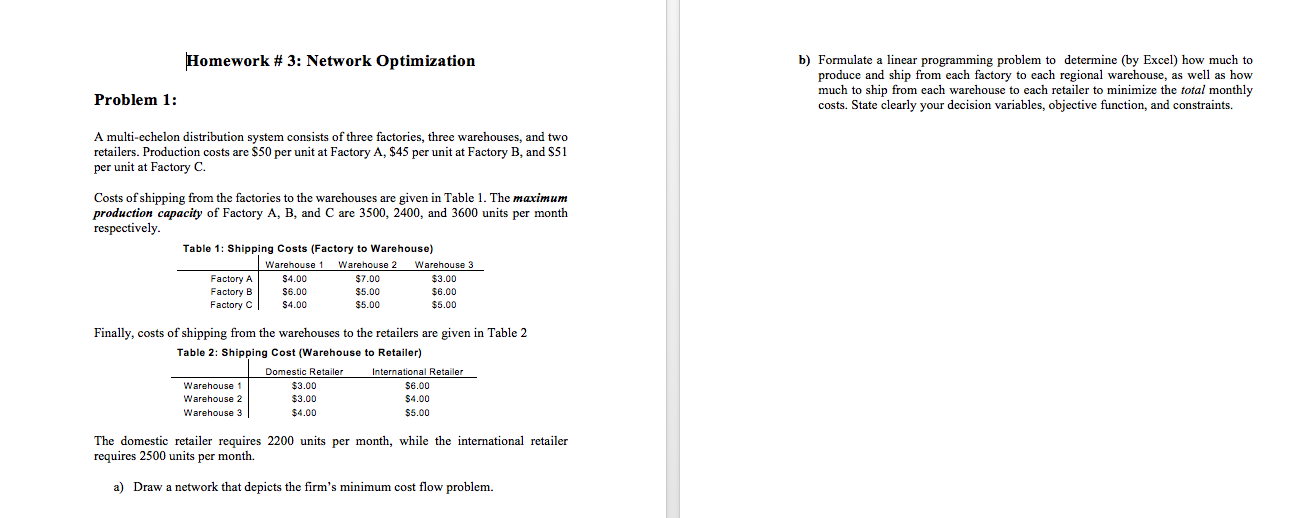

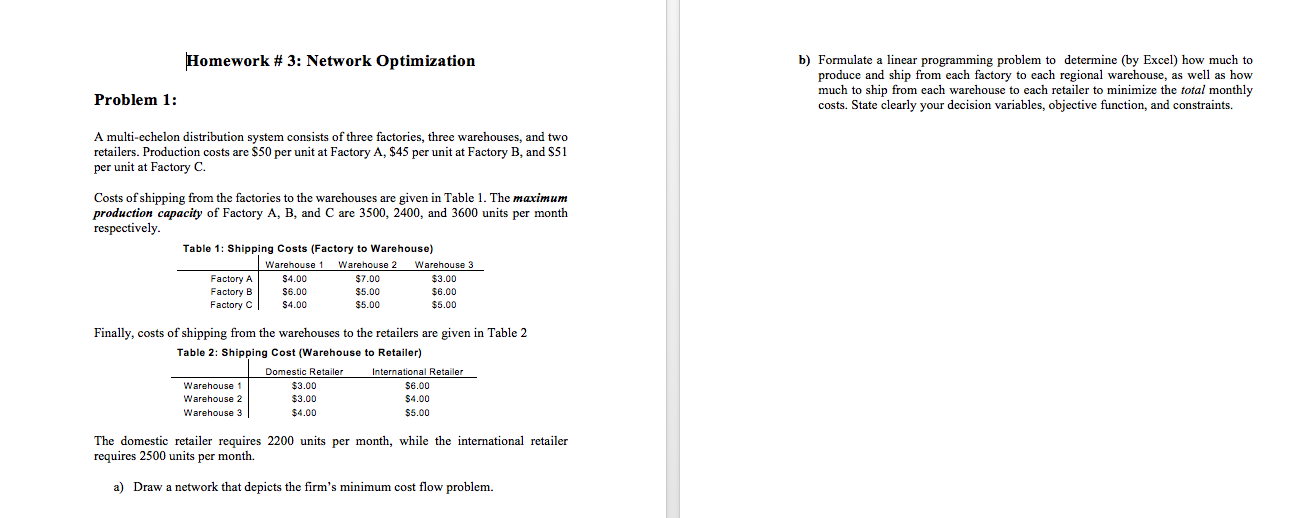

Homework # 3: Network Optimization b) Formulate a linear programming problem to determine (by Excel) how much to produce and ship from each factory to each regional warehouse, as well a much to ship from each warehouse to each retailer to minimize the total monthly costs. State clearly your decision variables, objective function, and constraints. Problem 1: A multi-echelon distribution system consists of three factories, three warehouses, and two retailers. Production costs are $50 per unit at Factory A, $45 per unit at Factory B, and $51 per unit at Factory C. Costs of shipping from the factories to the warehouses are given in Table 1. The maximum production capacity of Factory A, B, and C are 3500, 2400, and 3600 units per month respectively. Table 1: Shipping Costs (Factory to Warehouse) Warehouse 1 Warehouse 2 Warehouse 3 Factory A $4.00 $7.00 $3.00 Factory B $6.00 $5.00 $6.00 Factory c $4.00 $5.00 $5.00 Finally, costs of shipping from the warehouses to the retailers are given in Table 2 Table 2: Shipping Cost (Warehouse to Retailer) Domestic Retailer International Retailer Warehouse 1 $3.00 $6.00 Warehouse 2 $3.00 $4.00 Warehouse 3 $4.00 $5.00 The domestic retailer requires 2200 units per month, while the international retailer requires 2500 units per month. a) Draw a network that depicts the firm's minimum cost flow problem. Homework # 3: Network Optimization b) Formulate a linear programming problem to determine (by Excel) how much to produce and ship from each factory to each regional warehouse, as well a much to ship from each warehouse to each retailer to minimize the total monthly costs. State clearly your decision variables, objective function, and constraints. Problem 1: A multi-echelon distribution system consists of three factories, three warehouses, and two retailers. Production costs are $50 per unit at Factory A, $45 per unit at Factory B, and $51 per unit at Factory C. Costs of shipping from the factories to the warehouses are given in Table 1. The maximum production capacity of Factory A, B, and C are 3500, 2400, and 3600 units per month respectively. Table 1: Shipping Costs (Factory to Warehouse) Warehouse 1 Warehouse 2 Warehouse 3 Factory A $4.00 $7.00 $3.00 Factory B $6.00 $5.00 $6.00 Factory c $4.00 $5.00 $5.00 Finally, costs of shipping from the warehouses to the retailers are given in Table 2 Table 2: Shipping Cost (Warehouse to Retailer) Domestic Retailer International Retailer Warehouse 1 $3.00 $6.00 Warehouse 2 $3.00 $4.00 Warehouse 3 $4.00 $5.00 The domestic retailer requires 2200 units per month, while the international retailer requires 2500 units per month. a) Draw a network that depicts the firm's minimum cost flow