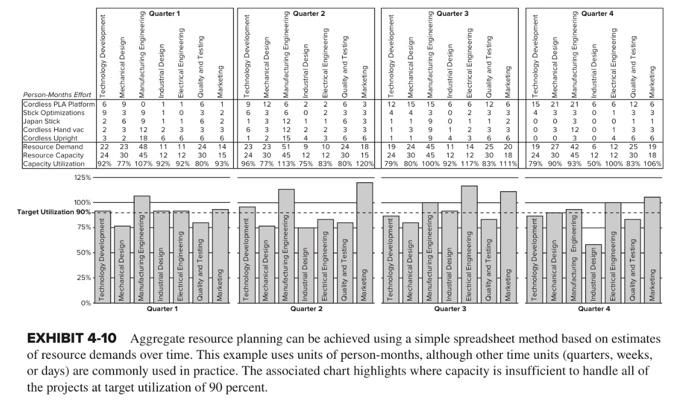

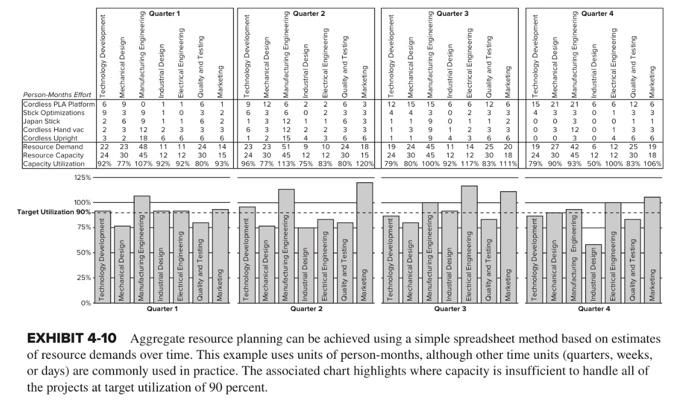

How might an organization be able to address the shortage of manufacturing engineers identified by the aggregate project planning analysis shown in Exhibit 4-10? List five ways to possibly increase the capacity and five ways to reduce the demand for manufac- turing engineers.

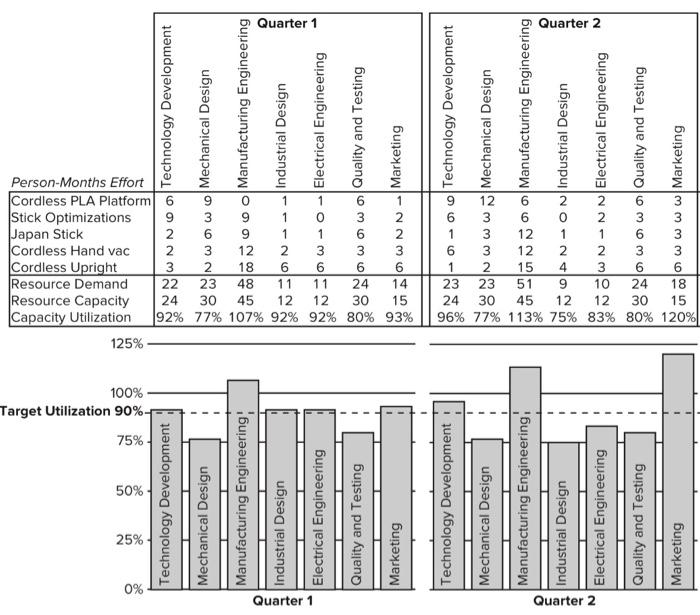

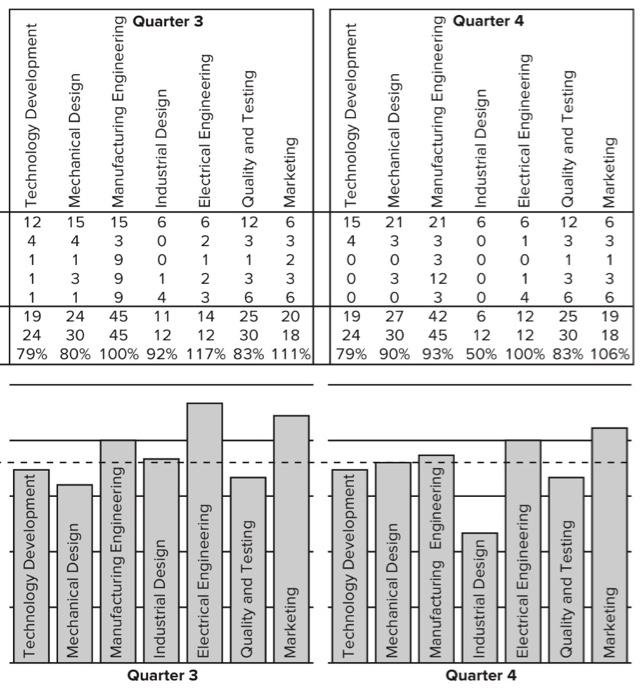

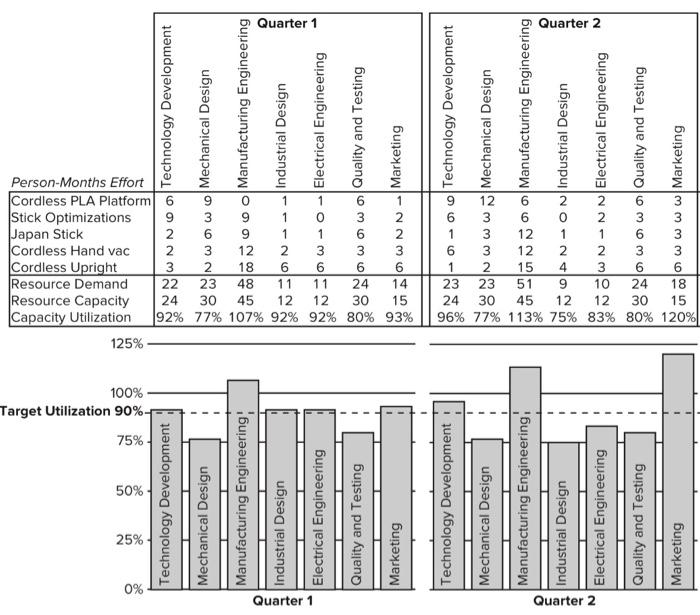

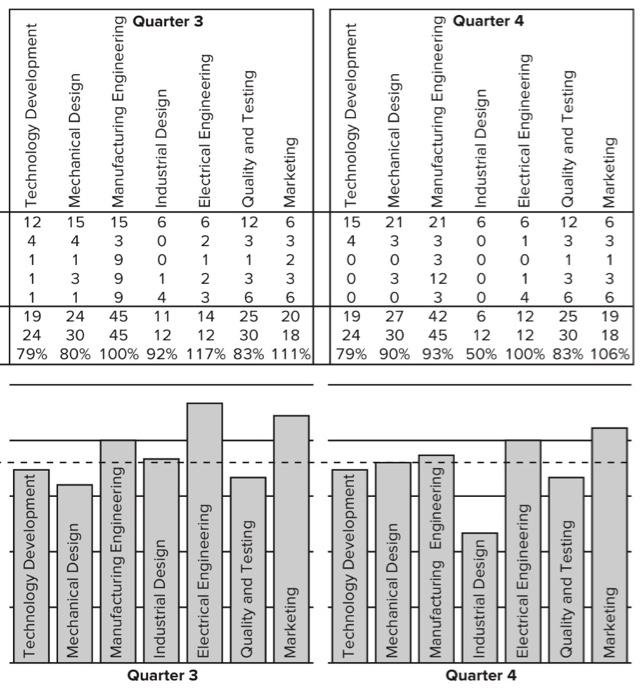

Quarter 1 Quarter 2 Quarter Quarter 4 Technology Development Mechanical Design Manufacturing Engineering Industrial Design - Electrical Engineering w Quality and Testing Technology Development w Mechanical Design Maracturing Engineering ON Industrial Design ectrical Engineering NN-Marketing w Quality and Testing Technology Development Manufacturing Engineering Mechanical Design Marketing industrial Design Quality and Testing Ne Electrical Engineering ww Marketing Technology Development www Manufacturing Engineering industrial Design Sowow Mechanical Design - Electrical Engineering Quality and Testing a low-warketing - 1- Person Months Em Cordless PLA Platform Stick Optimizations Japan Stick 9 . 12 Cordless Hand vac 2. 14 2 2 3 Cordless Upright 2 10 56 3 D Resource Demand 22 23 4 11 11 24 14 23 23 51 1024 18 Resource Capacity 24 30 45 12 12 30 15 24 30 45 12 12 30 15 Capacity Utilization 92% 77% 107% 92% 92% 80% 93, 96% 77%. 113% 75% 83% 80%, 1200 125% - E 9 E 9 O O 0 D le 94 1924 4511 24 30 45 12 79% 80% 100% 92% 12 30 17% 83% 18 115 5 12 25 45 12 12 30 79% 90% 93% 50100% 83% 106 100 Target Utilization 90%- 75 50% Technology Development Mechanical Design Manufacturing Engineering Industrial Design Electrical Engineering Quity and Testing Technology Development Mechanical Design Manufacturing Engineering industrial Design Electrical Engineering Technology Development Quality and Testing Manufacturing Engineering, Marketing Mechanical Design Electrical Engineering Industrial Design Technology Development Marketing Qualty and Testing Mancturing Engineering Electrical Engineering Mechanical Design Marketing Industrial Design Qually and Testing Marketing Quarter 1 Quarter 2 Quarter Quarter 4 EXHIBIT 4-10 Aggregate resource planning can be achieved using a simple spreadsheet method based on estimates of resource demands over time. This example uses units of person-months, although other time units (quarters, weeks, or days) are commonly used in practice. The associated chart highlights where capacity is insufficient to handle all of the projects target utilization of 90 percent. Quarter 1 Quarter 2 NNO Technology Development wow Mechanical Design ooooo Manufacturing Engineering Industrial Design -O-Electrical Engineering WOW Quality and Testing Technology Development www Mechanical Design Manufacturing Engineering WNN-Marketing -On Industrial Design N N N Electrical Engineering wow Quality and Testing wwww Marketing Person-Months Effort Cordless PLA Platform 6 Stick Optimizations 1 Japan Stick 1 Cordless Hand vac 2 3 Cordless Upright 3 6 6 6 Resource Demand 22 23 48 11 11 24 14 Resource Capacity 24 30 45 12 12 30 15 Capacity Utilization 92% 77% 107% 92% 92% 80% 93% 125% o 12 2 1 2 15 4 3 23 23 51 9 10 24 24 30 45 12 12 30 15 96% 77% 113% 75% 83% 80% 120% 100% Target Utilization 90%- 75% 50% Technology Development Mechanical Design Manufacturing Engineering Industrial Design Electrical Engineering Quality and Testing Technology Development Manufacturing Engineeringi Mechanical Design Marketing Electrical Engineering 25% Industrial Design Quality and Testing Marketing 0% Quarter 1 Quarter 2 Technology Development 4 12 Technology Development Mechanical Design W - Mechanical Design Manufacturing Engineering! Cow Manufacturing Engineering Quarter 3 Industrial Design 24 19 1 1 1 30 24 1 45 45 79% 80% 100% 92% 117% 83% 111% 12 11 4 1 12 14 30 25 18 20 6 o o Industrial Design Quarter 3 Electrical Engineering WNNO Electrical Engineering Quality and Testing > W - Quality and Testing Marketing WNW Marketing Technology Development: DOO Technology Development Mechanical Design wow Mechanical Design Manufacturing Engineering www Manufacturing Engineering Quarter 4 Industrial Design 24 19 30 27 45 42 79% 90% 93% 50% 100% 83% 106% 12 6 0 12 12 4 1 30 25 18 19 6 o o Industrial Design Quarter 4 Electrical Engineering o Electrical Engineering Quality and Testing WW Quality and Testing Marketing w - w Marketing Quarter 1 Quarter 2 Quarter Quarter 4 Technology Development Mechanical Design Manufacturing Engineering Industrial Design - Electrical Engineering w Quality and Testing Technology Development w Mechanical Design Maracturing Engineering ON Industrial Design ectrical Engineering NN-Marketing w Quality and Testing Technology Development Manufacturing Engineering Mechanical Design Marketing industrial Design Quality and Testing Ne Electrical Engineering ww Marketing Technology Development www Manufacturing Engineering industrial Design Sowow Mechanical Design - Electrical Engineering Quality and Testing a low-warketing - 1- Person Months Em Cordless PLA Platform Stick Optimizations Japan Stick 9 . 12 Cordless Hand vac 2. 14 2 2 3 Cordless Upright 2 10 56 3 D Resource Demand 22 23 4 11 11 24 14 23 23 51 1024 18 Resource Capacity 24 30 45 12 12 30 15 24 30 45 12 12 30 15 Capacity Utilization 92% 77% 107% 92% 92% 80% 93, 96% 77%. 113% 75% 83% 80%, 1200 125% - E 9 E 9 O O 0 D le 94 1924 4511 24 30 45 12 79% 80% 100% 92% 12 30 17% 83% 18 115 5 12 25 45 12 12 30 79% 90% 93% 50100% 83% 106 100 Target Utilization 90%- 75 50% Technology Development Mechanical Design Manufacturing Engineering Industrial Design Electrical Engineering Quity and Testing Technology Development Mechanical Design Manufacturing Engineering industrial Design Electrical Engineering Technology Development Quality and Testing Manufacturing Engineering, Marketing Mechanical Design Electrical Engineering Industrial Design Technology Development Marketing Qualty and Testing Mancturing Engineering Electrical Engineering Mechanical Design Marketing Industrial Design Qually and Testing Marketing Quarter 1 Quarter 2 Quarter Quarter 4 EXHIBIT 4-10 Aggregate resource planning can be achieved using a simple spreadsheet method based on estimates of resource demands over time. This example uses units of person-months, although other time units (quarters, weeks, or days) are commonly used in practice. The associated chart highlights where capacity is insufficient to handle all of the projects target utilization of 90 percent. Quarter 1 Quarter 2 NNO Technology Development wow Mechanical Design ooooo Manufacturing Engineering Industrial Design -O-Electrical Engineering WOW Quality and Testing Technology Development www Mechanical Design Manufacturing Engineering WNN-Marketing -On Industrial Design N N N Electrical Engineering wow Quality and Testing wwww Marketing Person-Months Effort Cordless PLA Platform 6 Stick Optimizations 1 Japan Stick 1 Cordless Hand vac 2 3 Cordless Upright 3 6 6 6 Resource Demand 22 23 48 11 11 24 14 Resource Capacity 24 30 45 12 12 30 15 Capacity Utilization 92% 77% 107% 92% 92% 80% 93% 125% o 12 2 1 2 15 4 3 23 23 51 9 10 24 24 30 45 12 12 30 15 96% 77% 113% 75% 83% 80% 120% 100% Target Utilization 90%- 75% 50% Technology Development Mechanical Design Manufacturing Engineering Industrial Design Electrical Engineering Quality and Testing Technology Development Manufacturing Engineeringi Mechanical Design Marketing Electrical Engineering 25% Industrial Design Quality and Testing Marketing 0% Quarter 1 Quarter 2 Technology Development 4 12 Technology Development Mechanical Design W - Mechanical Design Manufacturing Engineering! Cow Manufacturing Engineering Quarter 3 Industrial Design 24 19 1 1 1 30 24 1 45 45 79% 80% 100% 92% 117% 83% 111% 12 11 4 1 12 14 30 25 18 20 6 o o Industrial Design Quarter 3 Electrical Engineering WNNO Electrical Engineering Quality and Testing > W - Quality and Testing Marketing WNW Marketing Technology Development: DOO Technology Development Mechanical Design wow Mechanical Design Manufacturing Engineering www Manufacturing Engineering Quarter 4 Industrial Design 24 19 30 27 45 42 79% 90% 93% 50% 100% 83% 106% 12 6 0 12 12 4 1 30 25 18 19 6 o o Industrial Design Quarter 4 Electrical Engineering o Electrical Engineering Quality and Testing WW Quality and Testing Marketing w - w Marketing