Question

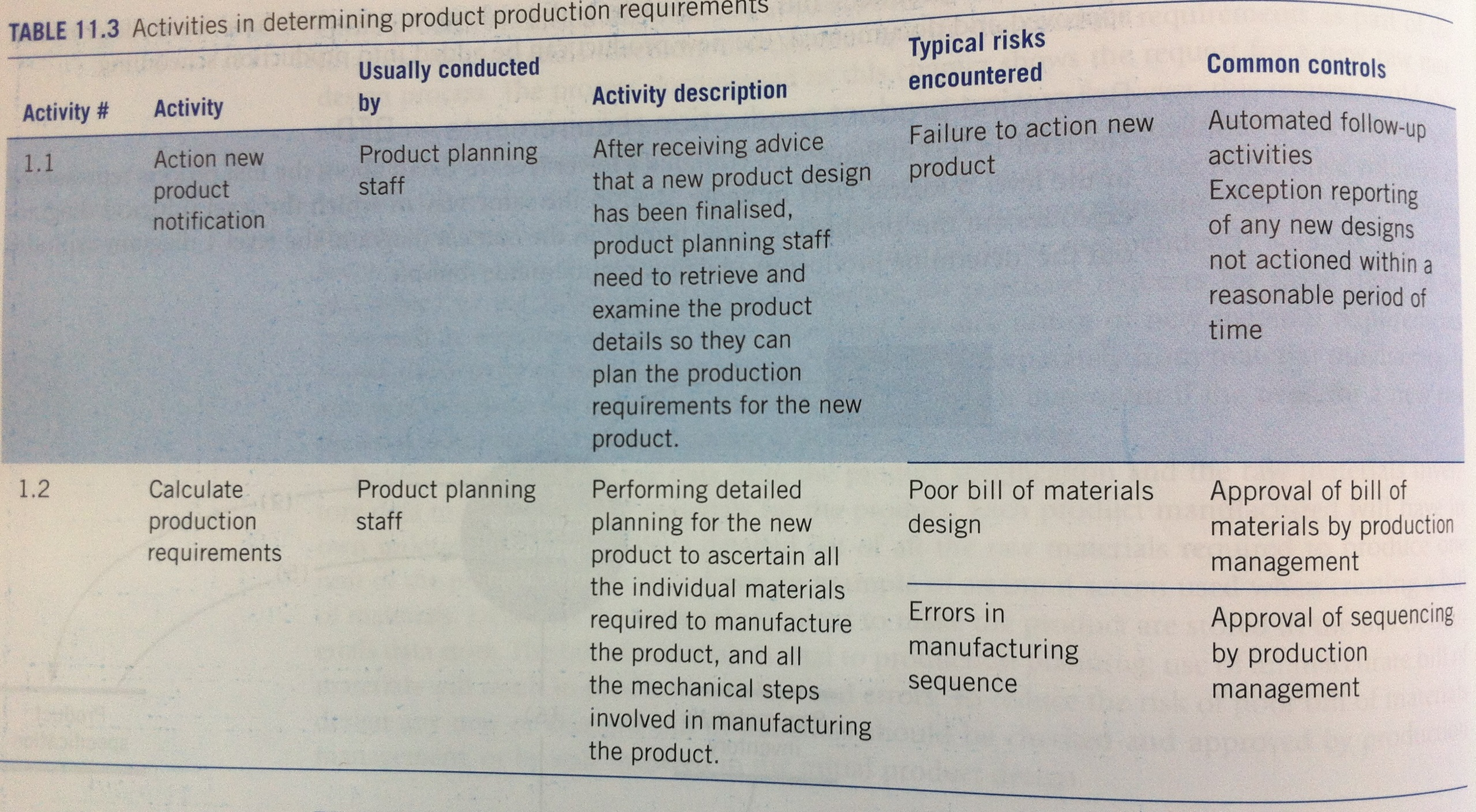

I got an incorrect answer for this first time. Im reposting. TABLE 11.3: Table 11.3 identifies three risks typically encountered when determining product production requirements.

I got an incorrect answer for this first time. Im reposting.

TABLE 11.3:

Table 11.3 identifies three risks typically encountered when determining product production requirements. Required: (a) Analyse the degree of exposure to each of these risks for the determine product production requirements process at AB Hi-Fi.

(b) Determine how many of the common controls described in table 11.3 are present in the determine product production requirements process at AB Hi-Fi.

(c) Prepare a short report suitable for senior management to explain how risky you think the determine product production requirements process is, and how comprehensive the current internal controls are. (2 paragraphs)

(d) Prepare a recommendation describing any changes you would like to make to the plan production process at AB Hi-Fi in order to reduce the level of risk.

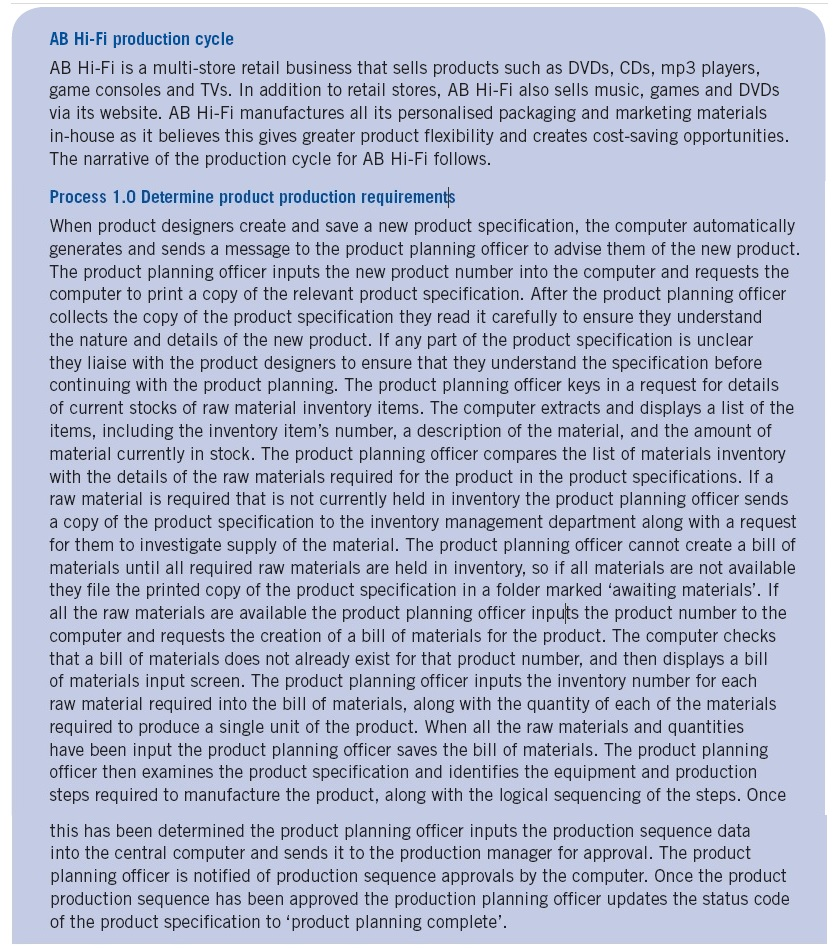

AB Hi-Fi production cycle AB Hi-Fi is a multi game consoles and TVs. In addition to retail stores, AB Hi-Fi also sells music, games and DVDs via its website. AB Hi-Fi manufactures all its personalised packaging and marketing materials in-house as it believes this gives greater product flexibility and creates cost-saving opportunities The narrative of the production cycle for AB Hi-Fi follows ore retail business that sells products such as DVDs, CDs, mp3 players, Process 1.0 Determine product production requiremen When product designers create and save a new product specification, the computer automatically generates and sends a message to the product planning officer to advise them of the new produ The product planning officer inputs the new product number into the computer and requests the computer to print a copy of the relevant product specification. After the product planning officer collects the copy of the product specification they read it carefully to ensure they understand the nature and details of the new product. If any part of the product specification is unclear they liaise with the product designers to ensure that they understand the specification before continuing with the product planning. The product planning officer keys in a request for details of current stocks of raw material inventory items. The computer extracts and displays a list of the items, including the inventory item's number, a description of the material, and the amount of material currently in stock. The product planning officer compares the list of materials inventory with the details of the raw materials required for the product in the product specifications. If a raw material is required that is a copy of the product specification to the inventory management department along with a request for them to investigate supply of the material. The product planning officer cannot create a bill of materials until all required raw materials are held in inventory, so if all materials are not available they file the printed copy of the product specification in a folder marked 'awaiting materials'. If all the raw materials are available the product planning officer inputs the product number to the computer and requests the creation of a bill of materials for the product. The computer checks that a bill of materials does not already exist for that product number, and then displays a bill of materials input screen. The product planning officer inputs the inventory number for each raw material required into the bill of materials, along with the quantity of each of the materials required to produce a single unit of the product. When all the raw materials and quantities have been input the product planning officer saves the bill of materials. The product planning officer then examines the product specification and identifies the equipment and production steps required to manufacture the product, along with the logical sequencing of the steps. Once t currently held in inventory the product planning officer sends this has been determined the product planning officer inputs the production sequence data into the central computer and sends it to the production manager for approval. The product planning officer is notified of production sequence approvals by the computer. Once the product production sequence has been approved the production planning officer updates the status code of the product specification to 'product planning completeStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started