i need all the questions answered in details please.

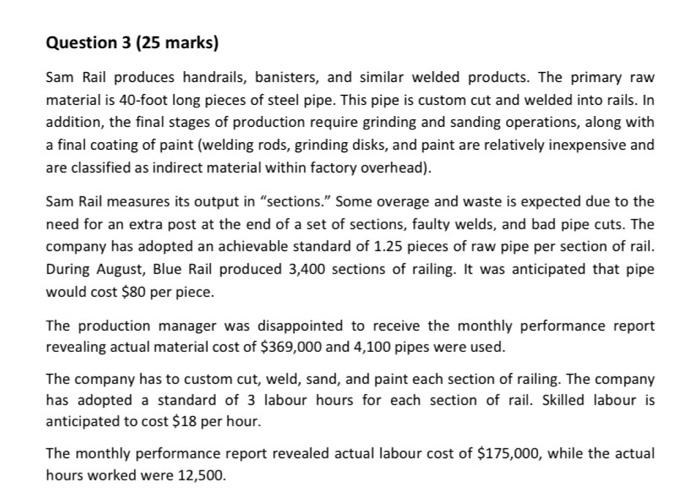

Question 3 (25 marks) Sam Rail produces handrails, banisters, and similar welded products. The primary raw material is 40-foot long pieces of steel pipe. This pipe is custom cut and welded into rails. In addition, the final stages of production require grinding and sanding operations, along with a final coating of paint (welding rods, grinding disks, and paint are relatively inexpensive and are classified as indirect material within factory overhead). Sam Rail measures its output in "sections." Some overage and waste is expected due to the need for an extra post at the end of a set of sections, faulty welds, and bad pipe cuts. The company has adopted an achievable standard of 1.25 pieces of raw pipe per section of rail. During August, Blue Rail produced 3,400 sections of railing. It was anticipated that pipe would cost $80 per piece. The production manager was disappointed to receive the monthly performance report revealing actual material cost of $369,000 and 4,100 pipes were used. The company has to custom cut, weld, sand, and paint each section of railing. The company has adopted a standard of 3 labour hours for each section of rail. Skilled labour is anticipated to cost $18 per hour. The monthly performance report revealed actual labour cost of $175,000, while the actual hours worked were 12,500. During August, Blue Rail produced 3,400 sections of railing. It was anticipated that pipe would cost $80 per piece. The production manager was disappointed to receive the monthly performance report revealing actual material cost of $369,000 and 4,100 pipes were used. The company has to custom cut, weld, sand, and paint each section of railing. The company has adopted a standard of 3 labour hours for each section of rail. Skilled labour is anticipated to cost $18 per hour. The monthly performance report revealed actual labour cost of $175,000, while the actual hours worked were 12,500. Sam Rail's variable factory overhead for August consisted primarily of indirect materials (welding rods, grinding disks, paint, etc.), indirect labour (inspector time, shop foreman, etc.), and other items. Extensive budgeting and analysis had been performed, and it was estimated that variable factory overhead should be applied at $10 per direct labour hour. During August, $105,000 was actually spent on variable factory overhead items. Sam Rail budgeted total fixed overhead at $72,000, but only $70,000 was spent. Sam Rail had planned on producing 4,000 rail systems during the month but only 3,400 systems were actually produced. Budgeted revenue was $1,024,000 while actual revenue was $ 900,000. Required: (a) Prepare a statement showing the actual and the budgeted profit for the actual production level. (4 marks) (b) Prepare an operating statement reconciling the budgeted profit to the actual profit, using as many variances as the data permit. (13 marks) (c) Write a report highlighting the main areas of concern based on the statement you have prepared in (b). Your report should comment on some plausible reasons for the materials and labour variances. (8 marks)