I need b,c,d excel sheets you created and your explanation

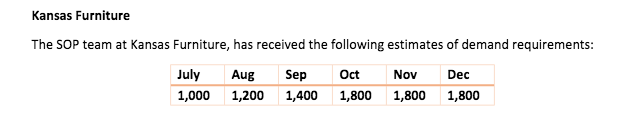

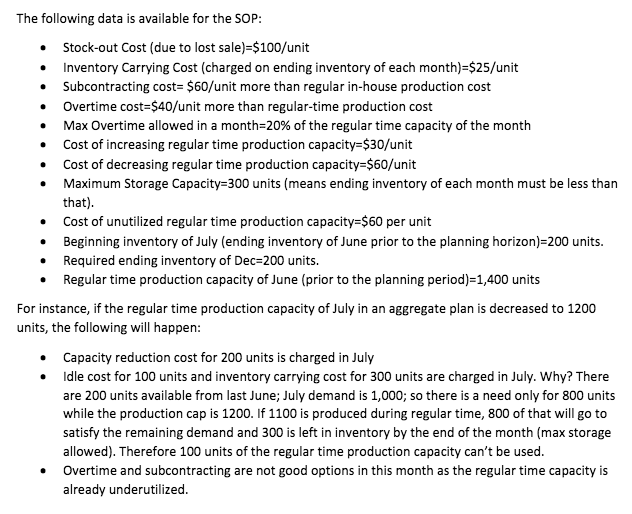

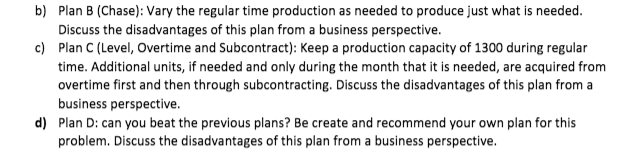

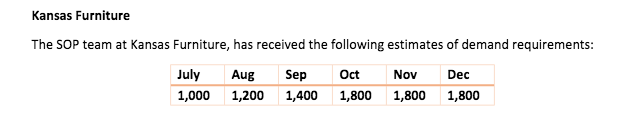

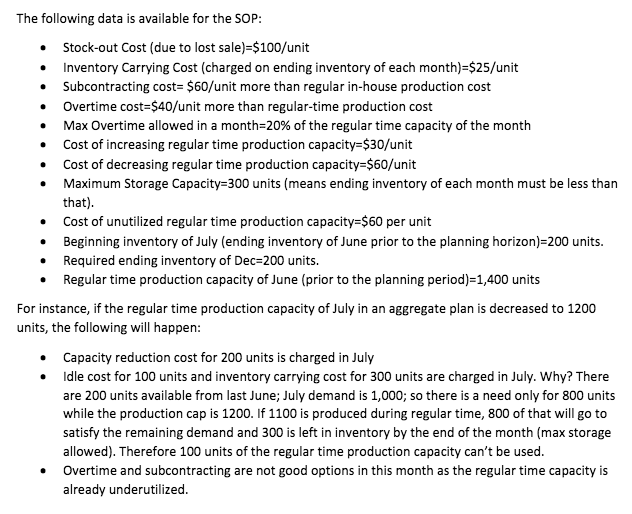

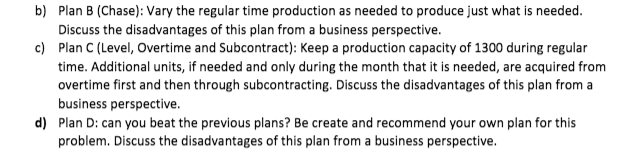

Kansas Furniture The SOP team at Kansas Furniture, has received the following estimates of demand requirements: July Aug Sep Oct Nov Dec 1,000 1,200 1,400 1,800 1,800 1,800 . . The following data is available for the SOP: Stock-out Cost (due to lost sale)=$100/unit Inventory Carrying Cost (charged on ending inventory of each month)=$25/unit Subcontracting cost= $60/unit more than regular in-house production cost Overtime cost=$40/unit more than regular-time production cost Max Overtime allowed in a month=20% of the regular time capacity of the month Cost of increasing regular time production capacity=$30/unit Cost of decreasing regular time production capacity=$60/unit Maximum Storage Capacity=300 units (means ending inventory of each month must be less than that). Cost of unutilized regular time production capacity=$60 per unit Beginning inventory of July (ending inventory of June prior to the planning horizon)=200 units. Required ending inventory of Dec=200 units. Regular time production capacity of June (prior to the planning period)=1,400 units For instance, if the regular time production capacity of July in an aggregate plan is decreased to 1200 units, the following will happen: Capacity reduction cost for 200 units is charged in July Idle cost for 100 units and inventory carrying cost for 300 units are charged in July. Why? There are 200 units available from last June; July demand is 1,000; so there is a need only for 800 units while the production cap is 1200. If 1100 is produced during regular time, 800 of that will go to satisfy the remaining demand and 300 is left in inventory by the end of the month (max storage allowed). Therefore 100 units of the regular time production capacity can't be used. Overtime and subcontracting are not good options in this month as the regular time capacity is already underutilized. b) Plan B (Chase): Vary the regular time production as needed to produce just what is needed. Discuss the disadvantages of this plan from a business perspective. c) Plan C (Level, Overtime and Subcontract): Keep a production capacity of 1300 during regular time. Additional units, if needed and only during the month that it is needed, are acquired from overtime first and then through subcontracting. Discuss the disadvantages of this plan from a business perspective. d) Plan D: can you beat the previous plans? Be create and recommend your own plan for this problem. Discuss the disadvantages of this plan from a business perspective. Kansas Furniture The SOP team at Kansas Furniture, has received the following estimates of demand requirements: July Aug Sep Oct Nov Dec 1,000 1,200 1,400 1,800 1,800 1,800 . . The following data is available for the SOP: Stock-out Cost (due to lost sale)=$100/unit Inventory Carrying Cost (charged on ending inventory of each month)=$25/unit Subcontracting cost= $60/unit more than regular in-house production cost Overtime cost=$40/unit more than regular-time production cost Max Overtime allowed in a month=20% of the regular time capacity of the month Cost of increasing regular time production capacity=$30/unit Cost of decreasing regular time production capacity=$60/unit Maximum Storage Capacity=300 units (means ending inventory of each month must be less than that). Cost of unutilized regular time production capacity=$60 per unit Beginning inventory of July (ending inventory of June prior to the planning horizon)=200 units. Required ending inventory of Dec=200 units. Regular time production capacity of June (prior to the planning period)=1,400 units For instance, if the regular time production capacity of July in an aggregate plan is decreased to 1200 units, the following will happen: Capacity reduction cost for 200 units is charged in July Idle cost for 100 units and inventory carrying cost for 300 units are charged in July. Why? There are 200 units available from last June; July demand is 1,000; so there is a need only for 800 units while the production cap is 1200. If 1100 is produced during regular time, 800 of that will go to satisfy the remaining demand and 300 is left in inventory by the end of the month (max storage allowed). Therefore 100 units of the regular time production capacity can't be used. Overtime and subcontracting are not good options in this month as the regular time capacity is already underutilized. b) Plan B (Chase): Vary the regular time production as needed to produce just what is needed. Discuss the disadvantages of this plan from a business perspective. c) Plan C (Level, Overtime and Subcontract): Keep a production capacity of 1300 during regular time. Additional units, if needed and only during the month that it is needed, are acquired from overtime first and then through subcontracting. Discuss the disadvantages of this plan from a business perspective. d) Plan D: can you beat the previous plans? Be create and recommend your own plan for this problem. Discuss the disadvantages of this plan from a business perspective