Answered step by step

Verified Expert Solution

Question

1 Approved Answer

I need help with parts 1 and 2 given the information above please and thank you A cheese plant produces 500,000 liters of liquid whey

I need help with parts 1 and 2 given the information above please and thank you

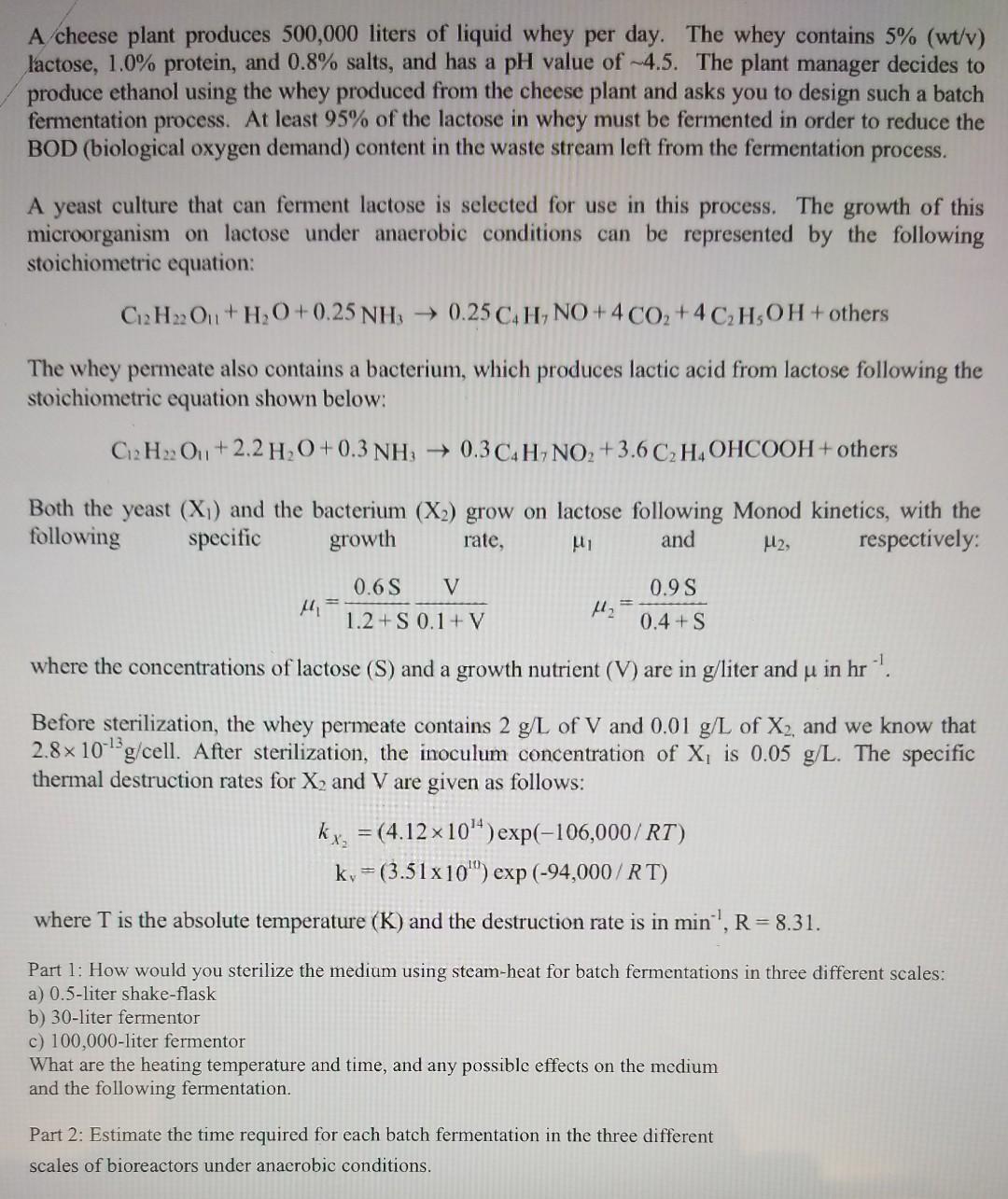

A cheese plant produces 500,000 liters of liquid whey per day. The whey contains 5% (wt/v) lactose, 1.0% protein, and 0.8% salts, and has a pH value of -4.5. The plant manager decides to produce ethanol using the whey produced from the cheese plant and asks you to design such a batch fermentation process. At least 95% of the lactose in whey must be fermented in order to reduce the BOD (biological oxygen demand) content in the waste stream left from the fermentation process. A yeast culture that can ferment lactose is selected for use in this process. The growth of this microorganism on lactose under anaerobic conditions can be represented by the following stoichiometric equation: C2H2O + H2O+0.25 NH 0.25C4H, NO+ 4CO2+4 CH OH + others The whey permeate also contains a bacterium, which produces lactic acid from lactose following the stoichiometric equation shown below: C2H220 +2.2 H2O+0.3 NH; 0.3C4H, NO. +3.6 C,H,OHCOOH + others + Both the yeast (Xi) and the bacterium (X2) grow on lactose following Monod kinetics, with the following specific growth rate, M1 and H2, respectively 0.6S V 0.9 S 1.2 +S 0.1+ V M 0.4+S where the concentrations of lactose (S) and a growth nutrient (V) are in g/liter and u in hr! Before sterilization, the whey permeate contains 2 g/L of V and 0.01 g/L of X2, and we know that 2.8 x 10-1g/cell. After sterilization, the inoculum concentration of X, is 0.05 g/L. The specific thermal destruction rates for X and V are given as follows: kx, = (4.12 x 10') exp(-106,000/RT) kv = (3.51x10") exp (-94,000/RT) where T is the absolute temperature (K) and the destruction rate is in min', R= 8.31. Part 1: How would you sterilize the medium using steam-heat for batch fermentations in three different scales: a) 0.5-liter shake-flask b) 30-liter fermentor c) 100,000-liter fermentor What are the heating temperature and time, and any possible effects on the medium and the following fermentation. Part 2: Estimate the time required for each batch fermentation in the three different scales of bioreactors under anaerobic conditions. A cheese plant produces 500,000 liters of liquid whey per day. The whey contains 5% (wt/v) lactose, 1.0% protein, and 0.8% salts, and has a pH value of -4.5. The plant manager decides to produce ethanol using the whey produced from the cheese plant and asks you to design such a batch fermentation process. At least 95% of the lactose in whey must be fermented in order to reduce the BOD (biological oxygen demand) content in the waste stream left from the fermentation process. A yeast culture that can ferment lactose is selected for use in this process. The growth of this microorganism on lactose under anaerobic conditions can be represented by the following stoichiometric equation: C2H2O + H2O+0.25 NH 0.25C4H, NO+ 4CO2+4 CH OH + others The whey permeate also contains a bacterium, which produces lactic acid from lactose following the stoichiometric equation shown below: C2H220 +2.2 H2O+0.3 NH; 0.3C4H, NO. +3.6 C,H,OHCOOH + others + Both the yeast (Xi) and the bacterium (X2) grow on lactose following Monod kinetics, with the following specific growth rate, M1 and H2, respectively 0.6S V 0.9 S 1.2 +S 0.1+ V M 0.4+S where the concentrations of lactose (S) and a growth nutrient (V) are in g/liter and u in hr! Before sterilization, the whey permeate contains 2 g/L of V and 0.01 g/L of X2, and we know that 2.8 x 10-1g/cell. After sterilization, the inoculum concentration of X, is 0.05 g/L. The specific thermal destruction rates for X and V are given as follows: kx, = (4.12 x 10') exp(-106,000/RT) kv = (3.51x10") exp (-94,000/RT) where T is the absolute temperature (K) and the destruction rate is in min', R= 8.31. Part 1: How would you sterilize the medium using steam-heat for batch fermentations in three different scales: a) 0.5-liter shake-flask b) 30-liter fermentor c) 100,000-liter fermentor What are the heating temperature and time, and any possible effects on the medium and the following fermentation. Part 2: Estimate the time required for each batch fermentation in the three different scales of bioreactors under anaerobic conditionsStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started