I need help with the attached question, especially part a. I dont know how to formulate LP equation with the stipulated question. Please help.

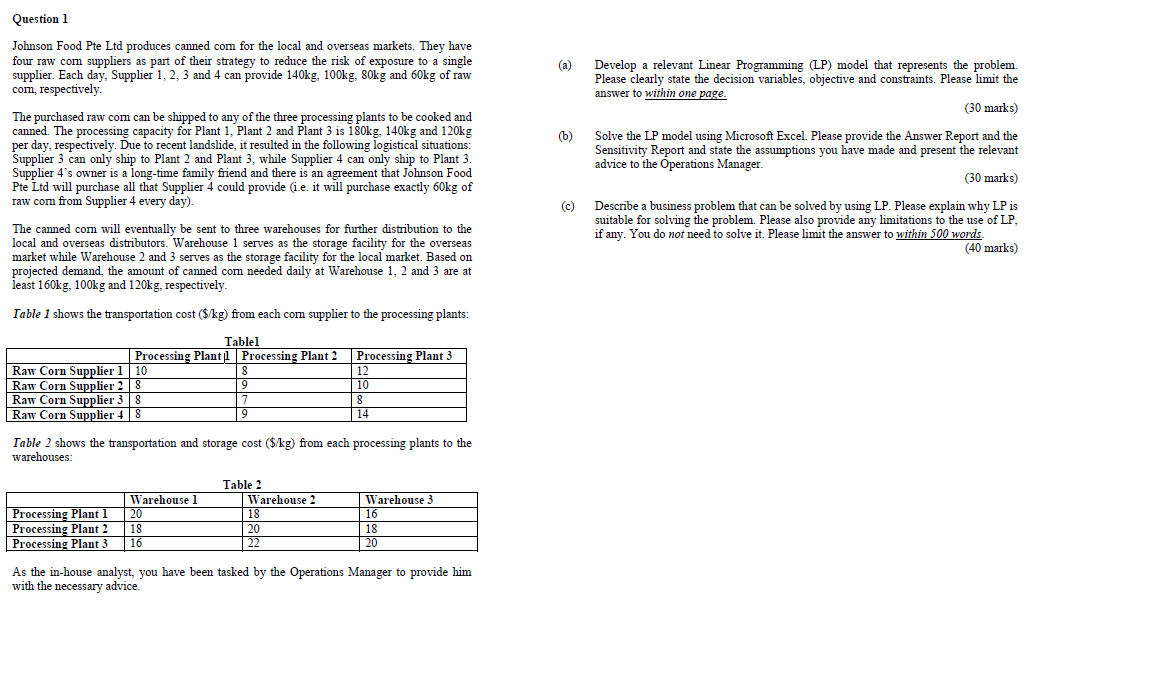

Question 1 Johnson Food Pte Led produces canned com for the local and overseas markets. They have four raw com suppliers as part of their strategy to reduce the risk of exposure to a single supplier. Each day, Supplier 1, 2, 3 and 4 can provide 140kg, 100kg, 80kg and 60kg of raw (a) Develop a relevant Linear Programming (LP) model that represents the problem. com, respectively. Please clearly state the decision variables, objective and constraints. Please limit the answer to within one page. The purchased raw com can be shipped to any of the three processing plants to be cooked and (30 marks) canned. The processing capacity for Plant 1, Plant 2 and Plant 3 is 180kg, 140kg and 120kg per day, respectively. Due to recent landslide, it resulted in the following logistical situations: b) Solve the LP model using Microsoft Excel. Please provide the Answer Report and the Supplier 3 can only ship to Plant 2 and Plant 3, while Supplier 4 can only ship to Plant 3. Sensitivity Report and state the assumptions you have made and present the relevant Supplier 4's owner is a long-time family friend and there is an agreement that Johnson Food advice to the Operations Manager. Pte Ltd will purchase all that Supplier 4 could provide (i.e. it will purchase exactly 60kg of (30 marks) raw com from Supplier 4 every day). (c) Describe a business problem that can be solved by using LP. Please explain why LP is The canned com will eventually be sent to three warehouses for further distribution to the suitable for solving the problem. Please also provide any limitations to the use of LP, local and overseas distributors. Warehouse 1 serves as the storage facility for the overseas if any. You do not need to solve it. Please limit the answer to within 300 words. market while Warehouse 2 and 3 serves as the storage facility for the local market. Based on (40 marks) projected demand, the amount of canned com needed daily at Warehouse 1, 2 and 3 are at least 160kg, 100kg and 120kg, respectively. Table 1 shows the transportation cost ($/kg) from each com supplier to the processing plants: Tablel Processing Plant ] |Processing Plant 2 Processing Plant 3 Raw Corn Supplier 1 |10 8 12 Raw Corn Supplier 2 |8 10 Raw Corn Supplier 3|8 8 Raw Corn Supplier 4 8 14 Table 2 shows the transportation and storage cost ($/kg) from each processing plants to the warehouses Table 2 Warehouse 1 |Warehouse 2 Warehouse 3 Processing Plant ] 20 18 16 Processing Plant 2 18 Processing Plant 3 16 20 22 18 20 As the in-house analyst, you have been tasked by the Operations Manager to provide him with the necessary advice