i need help with these problems please

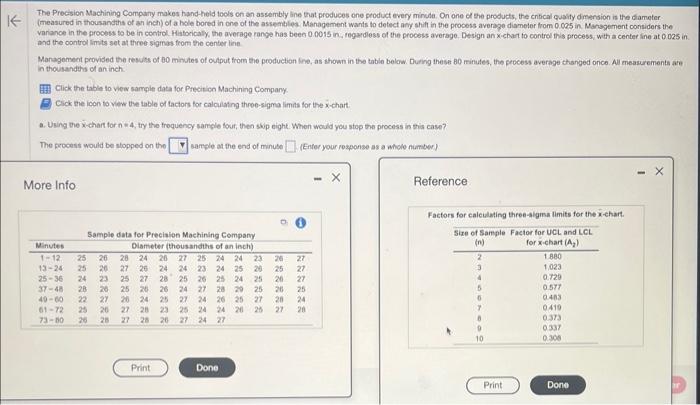

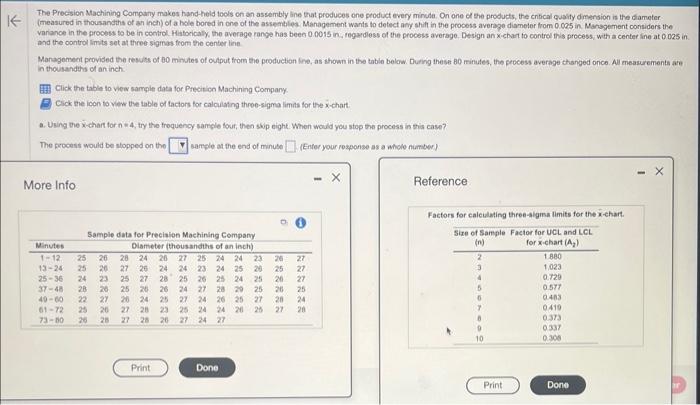

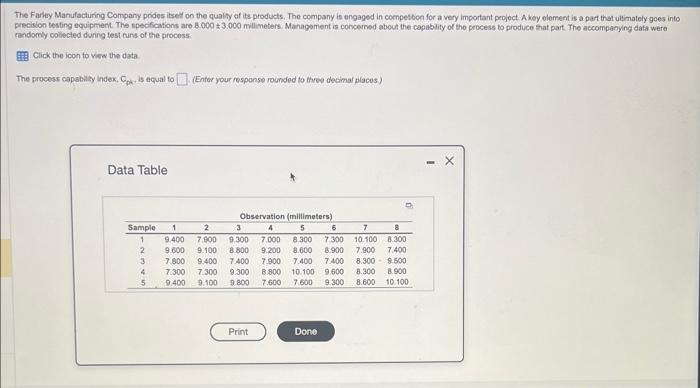

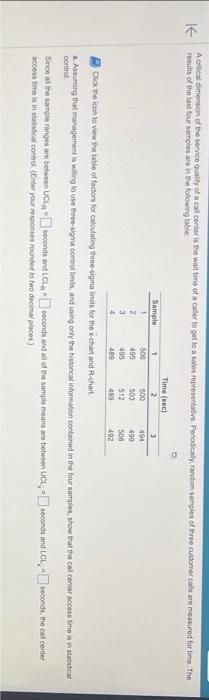

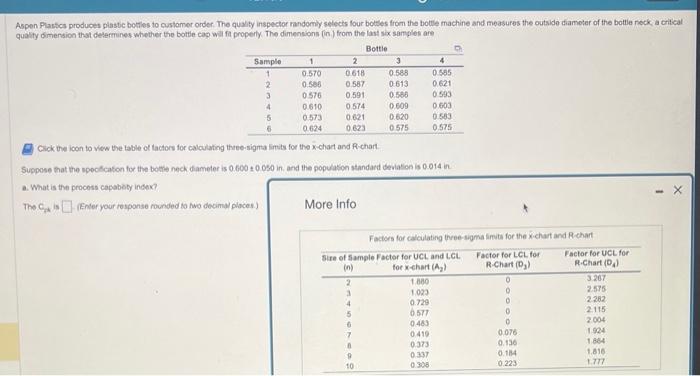

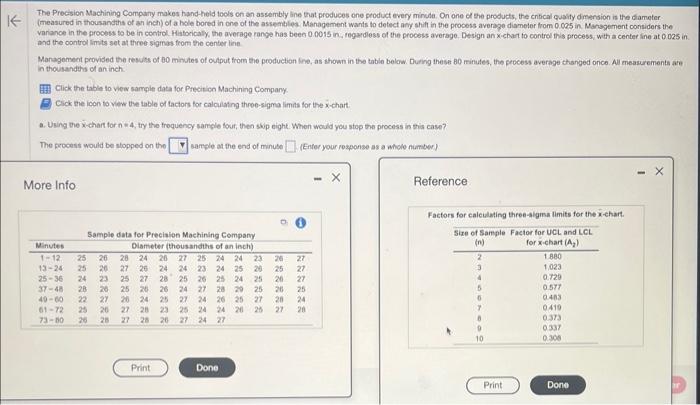

The Prectsion Machining Company makes hand-held tools on an assembly ine tenat produces one product every minude. On one of the products, the entical qualify dimersion is the diameter (measured in thousanths of an inch) of a hole bored in one of the assembles. Management wants to detect anj shift in the process averape dianeler from 0.005 in. Manspement considers the variance in the process to be in control Hatocicaly, the average range has been 0.0015 in, regardess of the process average. Design an xichar to contrel this process, with a center ine at 0.025 in. and the control innits set at three sigmas from the center line Management provised the rewits of too minutes of cutput from the peoduction ine, as thown in the tabia belaw. During these 80 minutes, the process average changed once. Al measurements are In thousandis of an inch. Click the table to view sampie data for Precition Machining Compary. Cick the icon to view the table of taciors for calcuiating throe-sigma limits for the x-chart a. Using the x-chart for n=4, try the troquency sargle tout, then skip eight. When would you stop the process in tis case? The procest would be stopped on the sample at the end of minuse (Enter your response as a whole number) More Info Reference Factors for calculating three-alginu limits for the x-ehart. The Farley Manufacturing Company prides itsey on the qualis of its products. The company is engaged in compescon for a very important peojoct A koy element is a part that ultimately goes into precision testing equipment. The specfications are 80003.000 milimeters. Management is concerned about the capablity of tho process to produce that part. The accompanying data were eandomy collected doring test runs of the procoss Click the icon to wies the data. The process capbbility index, Cpk+ is equal to (Enter your response rounded to three decimal places) Data Table A cilical dimension of the sevice qualcy of a call center is the wad tme of a caller to get la a sabes representabive. Penodcaly, tandom sampins of three cistomer calls are measured for ime. The Tesults of the last four sainples are in tefe folowing thote. Clok ne icon lo view the table of faclons for calculating three sigma imuis tor the x-char and R-chart. n. Assuming thw management is wiling to use thee-sigma conteol limis, and using only the hishoncat informason contained in the four samples, show that the cal centor acosse pime a in staisticat contral Aspen Plastics produces plaste bottles to custamer order. The qualiy inspector randomiy selects lour botses from the botle machine and measures the outside diameter of the bottle neck, a criteal quality dimension that delermines whether the botile cag will fa properly The dimensions (in) from the lasi six samples are Cick the icon to view the table of tactors for calculating thee-sigma insits for the x-chart and R-chart Suppose that the spectication tor the bente neck dameter is 0.6000.050 in. and the populason standard deviation is 0.014 in a. What is the process capabety indax? The Cpk is (Enier your response rounded to heo desimal places.) More Info The Prectsion Machining Company makes hand-held tools on an assembly ine tenat produces one product every minude. On one of the products, the entical qualify dimersion is the diameter (measured in thousanths of an inch) of a hole bored in one of the assembles. Management wants to detect anj shift in the process averape dianeler from 0.005 in. Manspement considers the variance in the process to be in control Hatocicaly, the average range has been 0.0015 in, regardess of the process average. Design an xichar to contrel this process, with a center ine at 0.025 in. and the control innits set at three sigmas from the center line Management provised the rewits of too minutes of cutput from the peoduction ine, as thown in the tabia belaw. During these 80 minutes, the process average changed once. Al measurements are In thousandis of an inch. Click the table to view sampie data for Precition Machining Compary. Cick the icon to view the table of taciors for calcuiating throe-sigma limits for the x-chart a. Using the x-chart for n=4, try the troquency sargle tout, then skip eight. When would you stop the process in tis case? The procest would be stopped on the sample at the end of minuse (Enter your response as a whole number) More Info Reference Factors for calculating three-alginu limits for the x-ehart. The Farley Manufacturing Company prides itsey on the qualis of its products. The company is engaged in compescon for a very important peojoct A koy element is a part that ultimately goes into precision testing equipment. The specfications are 80003.000 milimeters. Management is concerned about the capablity of tho process to produce that part. The accompanying data were eandomy collected doring test runs of the procoss Click the icon to wies the data. The process capbbility index, Cpk+ is equal to (Enter your response rounded to three decimal places) Data Table A cilical dimension of the sevice qualcy of a call center is the wad tme of a caller to get la a sabes representabive. Penodcaly, tandom sampins of three cistomer calls are measured for ime. The Tesults of the last four sainples are in tefe folowing thote. Clok ne icon lo view the table of faclons for calculating three sigma imuis tor the x-char and R-chart. n. Assuming thw management is wiling to use thee-sigma conteol limis, and using only the hishoncat informason contained in the four samples, show that the cal centor acosse pime a in staisticat contral Aspen Plastics produces plaste bottles to custamer order. The qualiy inspector randomiy selects lour botses from the botle machine and measures the outside diameter of the bottle neck, a criteal quality dimension that delermines whether the botile cag will fa properly The dimensions (in) from the lasi six samples are Cick the icon to view the table of tactors for calculating thee-sigma insits for the x-chart and R-chart Suppose that the spectication tor the bente neck dameter is 0.6000.050 in. and the populason standard deviation is 0.014 in a. What is the process capabety indax? The Cpk is (Enier your response rounded to heo desimal places.) More Info