Answered step by step

Verified Expert Solution

Question

1 Approved Answer

i need numbers 1 & 2 please 16.1 carol cagle has a repetitive manufacturing plant. the plant has an average inventory turnover of only 12

i need numbers 1 & 2 please

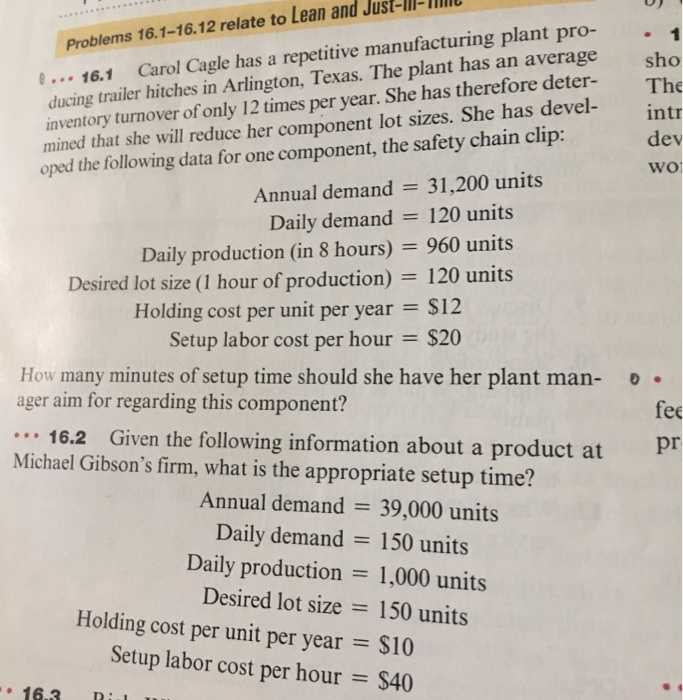

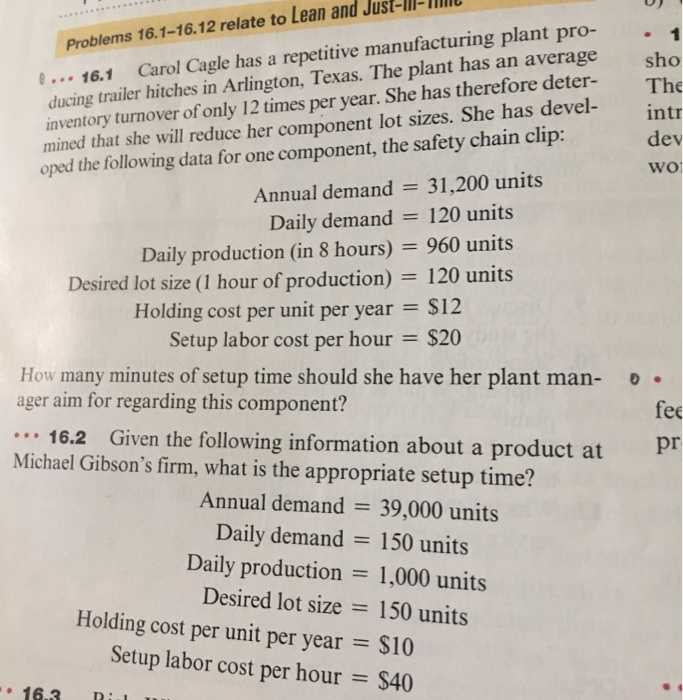

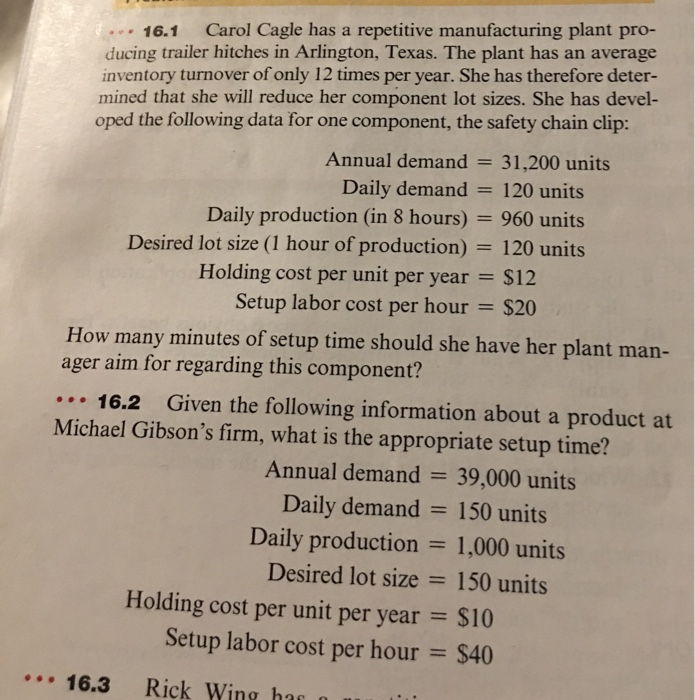

16.1 carol cagle has a repetitive manufacturing plant. the plant has an average inventory turnover of only 12 times per year. she has therefore, determined that she will reduce her component lot sizes. she has developed the following data for one component, the safety chain clip

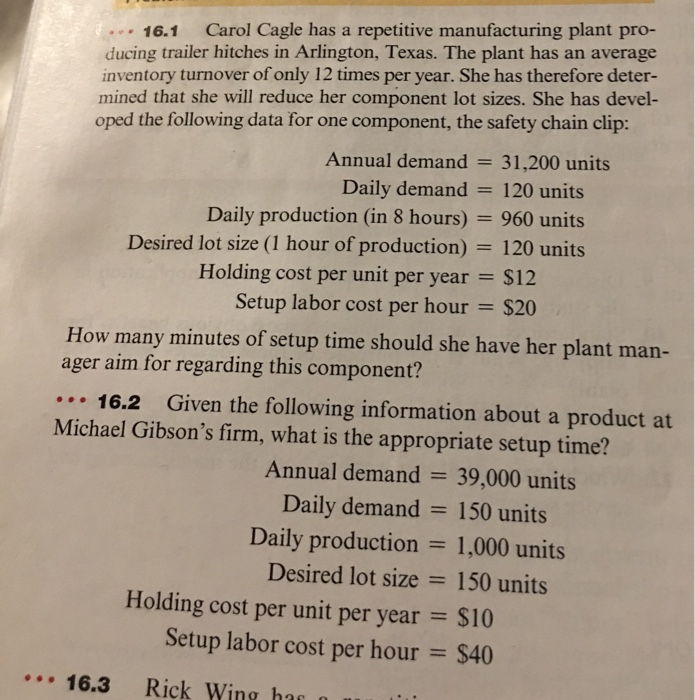

Problems 16.1-16.12 relate to Lean and Just-III-III sho The intr 2... 16.1 Carol Cagle has a repetitive manufacturing plant pro- ducing trailer hitches in Arlington, Texas. The plant has an average inventory turnover of only 12 times per year. She has therefore deter- mined that she will reduce her component lot sizes. She has devel- oped the following data for one component, the safety chain clip: dev wo Annual demand = 31,200 units Daily demand = 120 units Daily production (in 8 hours) = 960 units Desired lot size (1 hour of production) = 120 units Holding cost per unit per year = $12 Setup labor cost per hour = $20 D. fee pr How many minutes of setup time should she have her plant man- ager aim for regarding this component? ... 16.2 Given the following information about a product at Michael Gibson's firm, what is the appropriate setup time? Annual demand = 39,000 units Daily demand = 150 units Daily production = 1,000 units Desired lot size = 150 units Holding cost per unit per year = $10 Setup labor cost per hour = $40 16.3 1:1 T... 16.1 Carol Cagle has a repetitive manufacturing plant pro- ducing trailer hitches in Arlington, Texas. The plant has an average inventory turnover of only 12 times per year. She has therefore deter- mined that she will reduce her component lot sizes. She has devel- oped the following data for one component, the safety chain clip: Annual demand = 31,200 units Daily demand = 120 units Daily production (in 8 hours) = 960 units Desired lot size (1 hour of production) = 120 units Holding cost per unit per year = $12 Setup labor cost per hour = $20 How many minutes of setup time should she have her plant man- ager aim for regarding this component? ... 16.2 Given the following information about a product at Michael Gibson's firm, what is the appropriate setup time? Annual demand = 39,000 units Daily demand = 150 units Daily production = 1,000 units Desired lot size = 150 units Holding cost per unit per year = $10 Setup labor cost per hour = $40 ... 16.3 Rick Wing har 16.2 given the following informatikn about a profuct ar michael gibsons firm, what is the appropriate setup time?

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started