Read the below case and help me with the following question: Identify and prioritize the management accounting issues Full analysis of options and decisions to

Read the below case and help me with the following question:

Identify and prioritize the management accounting issues

Full analysis of options and decisions to be made including the status quo analysis

Justin Miller is a proud third-generation Canadian, having been born and raised in Toronto, the most populous city in Canada. His grandfather, Jason, had experience as a shoe shiner and cobbler, and eventually opened a shoe repair store after getting married in 1930. Since Justin’s grandmother had experience working as a seamstress, she decided to start making men’s leather shoes that catered to the financial district clientele. By combining technical know-how and experience on what the common issues and points of weakness were with most shoes, their hand-made leather shoes became highly sought after in downtown Toronto for their quality and durability. In 1940, Justin’s grandparents decided to incorporate the business as JM & Co. Leather Goods Company (JM & Co.), with a mission to manufacture and sell “high-quality leather footwear to urban professionals in Toronto”. By 1945, the company decided to expand into women’s shoes in order to cater to the underserved female clientele, by producing a pair of heels that were stylish and practical for all-day wear at the office. As the company’s reputation and business grew among the financial district, the company became synonymous with high-quality and durability, which the company strives to maintain. Throughout the years, the company has remained privately-owned by the Miller family, with a minority of the company’s shares owned by the family’s close friends, the Jones family.

When Justin’s father retired from the company in 2005, Justin became the President and CEO of the JM & Co. Armed with an MBA from Schulich Business School, he realized that automation would be key to the company’s ability to modernize and survive in the increasingly competitive market. As a result, the company added modern cutting, stitching, and sole pressing machines to increase manufacturing capacity while maintaining quality standards. Since many of the employees were long-term employees, substantial training was required to ensure that these seasoned employees are able to work efficiently and safely with the new high-tech machinery. Growing up, Justin visited the business after school, and became very close with these employees.

With the advice from his wife, Justin noticed that handbags and other small leather goods might also be a growing market that the company can enter. Justin also thought that this might be a good usage of the extra materials left over from shoe production. After performing the necessary market research to study the existing competitive landscape, it was determined that the company should expand into the production of women’s handbags. In order to promote the new line of products, the company began issuing semi-annual lookbooks to their existing loyal customers for Spring/Summer 2010. At this point, the company also decided to start building their online presence by creating a website and joining social media platforms.

After a recent health scare in 2020, Justin is considering slowing down in the next five to ten years, by slowly transitioning more responsibilities to his daughter, Jasmine. Jasmine has been a part of the company since 2017, after she completed her MBA from Schulich School of Business. As part of the succession plan, Jasmine has worked in multiple areas of the company to gain a stronger understanding of the company’s operations.

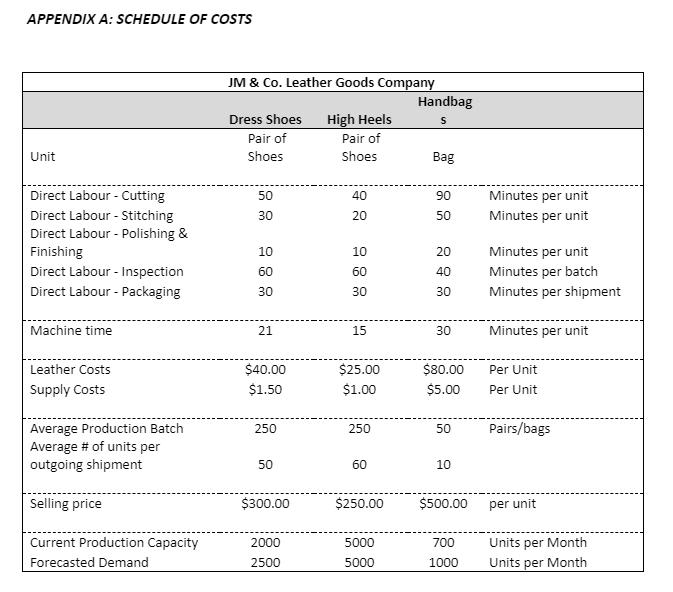

Currently, the company’s manufacturing facilities are located in Aurora, a suburb in the Greater Toronto Area (GTA) that is 50 km away from downtown Toronto. Justin believes that it is important to support the local economy by manufacturing in the GTA, but understands that at the end of the day, JM & Co. is a business that needs to be profitable. He has concerns about outsourcing, but is open to a discussion of the pros and cons. All of the cutting and stitching of raw materials occurs at the Aurora facility, along with inspections of the final products before shipment to customers. The raw material costs consist of the leather required for the shoes and bags, as well as miscellaneous indirect expenses (e.g. shoe laces, buckles and other hardware for shoes and bags, etc.). Based on the product, the amount of machine time required to cut and stitch can vary. Since a portion of the production of shoes and bags remains manual, each product has various amounts of direct labour required to complete certain tasks (e.g. sealing edges, polishing and staining, etc.). In order to develop a better understanding of the costs, Justin has provided the costs relating to JM & CO.’s three product lines (Appendix A).

Due to different production methods, each product line has a different production batch size. The average production batch sizes for each product line are: 250 pairs for dress shoes, 250 pairs for high heels, and 50 handbags. Each batch that is produced also requires an inspection, which has been included in the table above. Since dress shoes and high heels have more units per batch, they require 60 minutes of inspection per batch. A batch of handbags requires 40 minutes of inspection to ensure that the quality meets the company’s standards. Once inspection has been completed, the items are packaged and shipped to customers. For all three product lines, packaging takes 30 minutes per shipment. On average, each standard shipment of dress shoes includes 50 pairs; 60 pairs per shipment of high heels; and 10 bags per shipment of handbags.

As previously mentioned, the production of each product includes both direct labour and machine hours. Due to machinery limitations, the total machine hours cannot exceed 2,300 hours per month. Regarding the direct labour, the hourly labour rate varies based on the task that is being performed. The level of experience required for the role is dependent on the task, resulting in this different labour rates. For example, cutting and stitching require less expertise, so employees are more junior and have a $15 per hour rate. Employees performing polishing and finishing are more experienced, and therefore cost $18 per hour. Inspection is performed by employees with years of experience in order to have a trained eye to spot any minor perfections. Hence, employees performing the inspections cost $25 per hour. Packaging is performed by entry-level employees, costing $15 per hour. In addition to the direct labour wages, employees are also provided benefits. In order to attract talent, JM & Co. is generous with benefits, which costs the company 18% of total labour costs on average (not included in the hourly labour rates).

JM & Co. also has monthly overhead expenses that need to be considered. Total manufacturing overhead is $450,000 per month, including $55,000 in monthly machine repairs. It has been determined that the machine repairs costs are driven by machine hours. The remaining manufacturing overhead costs are driven by direct labour hours. The company also has a purchasing department, which incurs overhead expenses of $40,000 per month. This department orders products for the various product lines, which averages to be 10 purchase orders per month for dress shoes, 15 purchases orders per month for high heels, and 5 purchase orders per month for handbags. In addition to the aforementioned overhead costs, JM & Co. also spends $158,000 per month on other facility sustaining expenses, such as rent, President/CEO salary, Finance/Accounting functions, Human Resources, and other administrative functions. Justin has stated that he has looked into these expenses, and is unable to break them down by cost driver.

Due to the threat of obsolescence in the fashion industry, JM & Co. does not want to hold excess inventory. The company also has limited space in its facility to store inventory. Therefore, production quantities are in line with the amount they are expected to sell each month. Hence, any inventory held by JM & Co. is immaterial. Given the current economic environment, inflation is low enough to be considered negligible.

As a result of his recent health scare, Justin feels that there is some uncertainty with the future direction of the company. In addition, he is uncertain if growth within this industry is sustainable in the long-term. Therefore, he is unwilling to expand production capacity, even though JM & Co. is already manufacturing at full capacity.

After performing some research on how to increase sales, JM & Co. found a potential subcontractor to outsource some of the manufacturing. LB & Co. is located in Houston, Texas, and has the machines and experience required to manufacture high heels only. They have indicated that they have the capacity to produce 1,500 high heels at $55.00 per pair. If JM & Co. chooses to outsource to LB & Co., LB & Co. will be responsible for all raw materials (leather, supplies), cutting, stitching, polishing, and finishing the high heels. The completed products will then be sent back to JM & Co.’s facility in Aurora for inspection, packaging, and shipping. Since the manufacturing process will occur in LB & Co.’s production facilities, no machine hours will be needed at JM & Co. In addition, Justin estimates that by outsourcing 1,500 pairs of high heels, the purchasing department can cut their costs by $5,000 per month. Justin is on the fence about outsourcing, but also recognizes that this might free up capacity at JM & Co. to increase production of other product lines to meet the monthly demand.

Recently, JM & Co. has also been approached by a reputable chain of boutiques based in Toronto. Isabella’s Bags has ten locations in the GTA, with another 25 locations across other major cities in Canada and USA. The chain of boutiques is known for carrying premium-quality products that are fashion-forward, and has a loyal following of young, affluent women with discerning taste. The owner, Isabella, has indicated that she is interested in ordering 800 bags in the coming month, and willing to pay $425.00 per handbag. Justin realizes that even though this is lower than their regular selling price, it might be worth considering, due to the high volume of the order. Since Isabella’s Bags did not previously carry JM & Co. handbags, this order of 800 bags would be on top of the forecasted demand of 1,000 bags per month.

Justin and Jasmine recently approached you to get your advice on what the company should do. They are looking forward to the potential changes and would like to know what options they should take up.

APPENDIX A: SCHEDULE OF COSTS Unit Direct Labour - Cutting Direct Labour - Stitching Direct Labour - Polishing & Finishing Direct Labour - Inspection Direct Labour - Packaging Machine time Leather Costs Supply Costs Average Production Batch Average # of units per outgoing shipment Selling price Current Production Capacity Forecasted Demand JM & Co. Leather Goods Company Dress Shoes High Heels Pair of Pair of Shoes Shoes 50 40 30 20 10 10 60 60 30 30 21 15 $40.00 $25.00 $1.50 $1.00 250 250 50 60 $300.00 $250.00 2000 5000 2500 5000 Handbag S Bag 90 50 20 40 30 30 $80.00 $5.00 50 10 $500.00 700 1000 Minutes per unit Minutes per unit Minutes per unit Minutes per batch Minutes per shipment Minutes per unit Per Unit Per Unit Pairs/bags per unit Units per Month Units per Month

Step by Step Solution

3.39 Rating (149 Votes )

There are 3 Steps involved in it

Step: 1

The first management accounting issue is to decide whether to outsource the production of shoes or to keep the production inhouse The second issue is to decide what type of accounting system to use Th...

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started