Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Im not sure that we can achieve the, level of efficiency advocated by the study. In my opinion, the plant is operating efficiently for the

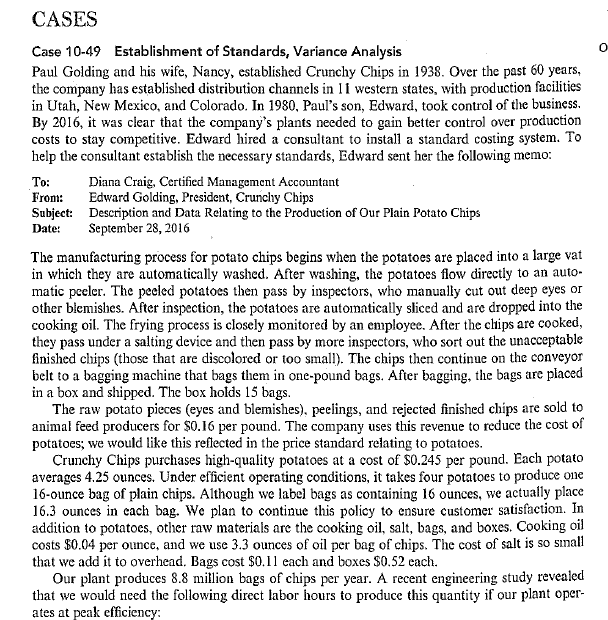

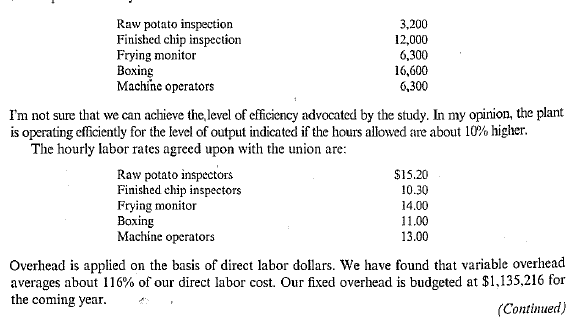

Im not sure that we can achieve the, level of efficiency advocated by the study. In my opinion, the plant is operating efficiently for the level of output indicated if the hours allowed are about \10 higher. The hourly labor rates agreed upon with the union are: Overhead is applied on the basis of direct labor dollars. We have found that variable overhead averages about \116 of our direct labor cost. Our fixed overhead is budgeted at \\( \\$ 1,135,216 \\) for the coming year. (Continued) Required: 1. Discuss the benefits of a standard costing system for Crunchy Chips. 2. Discuss the president's concern about using the result of the engineering study to set the labor standards. What standard would you recommend? 3. Form a group with two or three other students. Develop a standard cost sheet for Crunchy Chips' plain potato chips. Round all computations to four decimal places. 4. Suppose that the level of production was 8.8 million bags of potato chips for the year as planned. If 9.5 million pounds of potatoes were used, compute the materials usage variance for potatoes. CASES Case 10-49 Establishment of Standards, Variance Analysis Paul Golding and his wife, Nancy, established Crunchy Chips in 1938 . Over the past 60 years, the company has established distribution channels in 11 western states, with production facilities in Utah, New Mexico, and Colorado. In 1980, Paul's son, Edward, took control of the business. By 2016, it was clear that the company's plants needed to gain better control over production costs to stay competitive. Edward hired a consultant to install a standard costing system. To help the consultant establish the necessary standards, Edward sent her the following memo: \\( \\begin{array}{ll}\\text { To: } & \\text { Diana Craig, Certified Management Accountant } \\\\ \\text { From: } & \\text { Edward Golding, President, Crunchy Chips } \\\\ \\text { Subject: } & \\text { Description and Data Relating to the Production of Our Plain Potato Chips } \\\\ \\text { Date: } & \\text { September 28, 2016 }\\end{array} \\) The manufacturing process for potato chips begins when the potatoes are placed into a large vat in which they are automatically washed. After washing, the potatoes flow directly to an automatic peeler. The peeled potatoes then pass by inspectors, who manually cut out deep eyes or other blemishes. After inspection, the potatoes are automatically sliced and are dropped into the cooking oil. The frying process is closely monitored by an employee. After the chips are cooked, they pass under a salting device and then pass by more inspectors, who sort out the unacceptable finished clips (those that are discolored or too small). The chips then continue on the conveyor belt to a bagging machine that bags them in one-pound bags. After bagging, the bags are placed in a box and shipped. The box holds 15 bags. The raw potato pieces (eyes and blemishes), peelings, and rejected finished chips are sold to animal feed producers for \\( \\$ 0.16 \\) per pound. The company uses this revenue to reduce the cost of potatoes; we would like this reflected in the price standard relating to potatoes. Crunchy Chips purchases high-quality potatoes at a cost of \\( \\$ 0.245 \\) per pound. Each potato averages 4.25 ounces. Under efficient operating conditions, it takes four potatoes to produce one 16 -ounce bag of plain chips. Although we label bags as containing 16 ounces, we actually place 16.3 ounces in each bag. We plan to continue this policy to ensure customer satisfaction. In addition to potatoes, other raw materials are the cooking oil, salt, bags, and boxes. Cooking oil costs \\( \\$ 0.04 \\) per ounce, and we use 3.3 ounces of oil per bag of chips. The cost of salt is so small that we add it to overhead. Bags cost \\( \\$ 0.11 \\) each and boxes \\( \\$ 0.52 \\) each. Our plant produces 8.8 million bags of chips per year. A recent engineering study revealed that we would need the following direct labor hours to produce this quantity if our plant operates at peak efficiency

Im not sure that we can achieve the, level of efficiency advocated by the study. In my opinion, the plant is operating efficiently for the level of output indicated if the hours allowed are about \10 higher. The hourly labor rates agreed upon with the union are: Overhead is applied on the basis of direct labor dollars. We have found that variable overhead averages about \116 of our direct labor cost. Our fixed overhead is budgeted at \\( \\$ 1,135,216 \\) for the coming year. (Continued) Required: 1. Discuss the benefits of a standard costing system for Crunchy Chips. 2. Discuss the president's concern about using the result of the engineering study to set the labor standards. What standard would you recommend? 3. Form a group with two or three other students. Develop a standard cost sheet for Crunchy Chips' plain potato chips. Round all computations to four decimal places. 4. Suppose that the level of production was 8.8 million bags of potato chips for the year as planned. If 9.5 million pounds of potatoes were used, compute the materials usage variance for potatoes. CASES Case 10-49 Establishment of Standards, Variance Analysis Paul Golding and his wife, Nancy, established Crunchy Chips in 1938 . Over the past 60 years, the company has established distribution channels in 11 western states, with production facilities in Utah, New Mexico, and Colorado. In 1980, Paul's son, Edward, took control of the business. By 2016, it was clear that the company's plants needed to gain better control over production costs to stay competitive. Edward hired a consultant to install a standard costing system. To help the consultant establish the necessary standards, Edward sent her the following memo: \\( \\begin{array}{ll}\\text { To: } & \\text { Diana Craig, Certified Management Accountant } \\\\ \\text { From: } & \\text { Edward Golding, President, Crunchy Chips } \\\\ \\text { Subject: } & \\text { Description and Data Relating to the Production of Our Plain Potato Chips } \\\\ \\text { Date: } & \\text { September 28, 2016 }\\end{array} \\) The manufacturing process for potato chips begins when the potatoes are placed into a large vat in which they are automatically washed. After washing, the potatoes flow directly to an automatic peeler. The peeled potatoes then pass by inspectors, who manually cut out deep eyes or other blemishes. After inspection, the potatoes are automatically sliced and are dropped into the cooking oil. The frying process is closely monitored by an employee. After the chips are cooked, they pass under a salting device and then pass by more inspectors, who sort out the unacceptable finished clips (those that are discolored or too small). The chips then continue on the conveyor belt to a bagging machine that bags them in one-pound bags. After bagging, the bags are placed in a box and shipped. The box holds 15 bags. The raw potato pieces (eyes and blemishes), peelings, and rejected finished chips are sold to animal feed producers for \\( \\$ 0.16 \\) per pound. The company uses this revenue to reduce the cost of potatoes; we would like this reflected in the price standard relating to potatoes. Crunchy Chips purchases high-quality potatoes at a cost of \\( \\$ 0.245 \\) per pound. Each potato averages 4.25 ounces. Under efficient operating conditions, it takes four potatoes to produce one 16 -ounce bag of plain chips. Although we label bags as containing 16 ounces, we actually place 16.3 ounces in each bag. We plan to continue this policy to ensure customer satisfaction. In addition to potatoes, other raw materials are the cooking oil, salt, bags, and boxes. Cooking oil costs \\( \\$ 0.04 \\) per ounce, and we use 3.3 ounces of oil per bag of chips. The cost of salt is so small that we add it to overhead. Bags cost \\( \\$ 0.11 \\) each and boxes \\( \\$ 0.52 \\) each. Our plant produces 8.8 million bags of chips per year. A recent engineering study revealed that we would need the following direct labor hours to produce this quantity if our plant operates at peak efficiency Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started