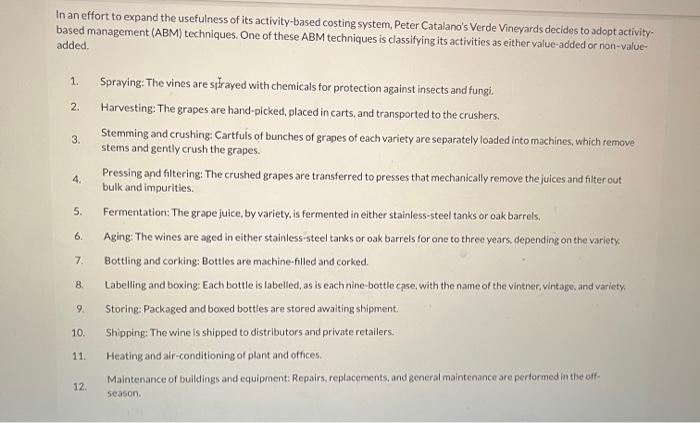

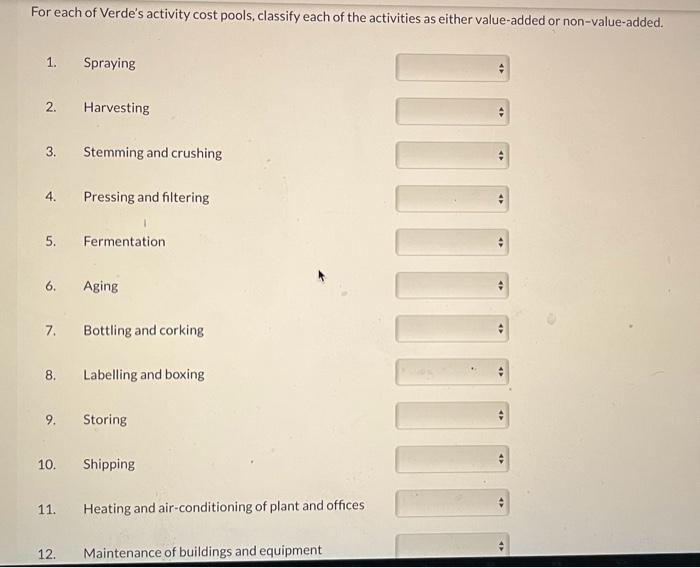

In an effort to expand the usefulness of its activity-based costing system, Peter Catalano's Verde Vineyards decides to adopt activitybased management (ABM) techniques. One of these ABM techniques is classifying its activities as either value-added or non-valueadded. 1. Spraying: The vines are strayed with chemicals for protection against insects and fungi. 2. Harvesting: The grapes are hand-picked, placed in carts, and transported to the crushers. 3. Stemming and crushing: Cartfuls of bunches of grapes of each variety are separately loaded into machines, which remove stems and gently crush the grapes. 4. Pressing and filtering: The crushed grapes are transferred to presses that mechanically remove the juices and filter out bulk and impurities. 5. Fermentation: The grape juice, by variety, is fermented in either stainless-steel tanks or oak barrels. 6. Aging: The wines are aged in either stainless-steel tanks or oak barrels for one to three years. depending on the variety. 7. Bottling and corking: Bottles are machine-filled and corked. 8. Labelling and boxing: Each bottle is labelled, as is each nine-bottle cpse, with the name of the vintner vintage, and variety. 9. Storing: Packoged and boxed bottles are stored awaiting shipment. 10. Shipping: The wine is shipped to distributors and private retailers. 11. Heating and air-conditioning of plant and offices. 12. Maintenance of buildings and equipment: Repairs, replacements, and general maintenance are periormed in the offseason. r non-value-added. In an effort to expand the usefulness of its activity-based costing system, Peter Catalano's Verde Vineyards decides to adopt activitybased management (ABM) techniques. One of these ABM techniques is classifying its activities as either value-added or non-valueadded. 1. Spraying: The vines are strayed with chemicals for protection against insects and fungi. 2. Harvesting: The grapes are hand-picked, placed in carts, and transported to the crushers. 3. Stemming and crushing: Cartfuls of bunches of grapes of each variety are separately loaded into machines, which remove stems and gently crush the grapes. 4. Pressing and filtering: The crushed grapes are transferred to presses that mechanically remove the juices and filter out bulk and impurities. 5. Fermentation: The grape juice, by variety, is fermented in either stainless-steel tanks or oak barrels. 6. Aging: The wines are aged in either stainless-steel tanks or oak barrels for one to three years. depending on the variety. 7. Bottling and corking: Bottles are machine-filled and corked. 8. Labelling and boxing: Each bottle is labelled, as is each nine-bottle cpse, with the name of the vintner vintage, and variety. 9. Storing: Packoged and boxed bottles are stored awaiting shipment. 10. Shipping: The wine is shipped to distributors and private retailers. 11. Heating and air-conditioning of plant and offices. 12. Maintenance of buildings and equipment: Repairs, replacements, and general maintenance are periormed in the offseason. r non-value-added