Question

In anticipation of the heating and cooling demands of the properties, Lance has decided to start a side business producing air filters. Because of the

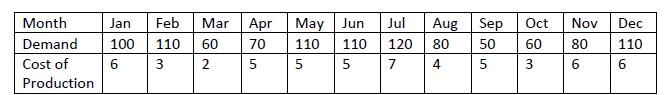

In anticipation of the heating and cooling demands of the properties, Lance has decided to start a side business producing air filters. Because of the demands on his time and varying production costs, Lance must be very strategic in determining his production schedule. He believes that he can produce no more than 100 air filters per month, but he can also hold inventory from one month to the next and he can outsource production. After consulting with Corin and other industry experts, he developed the following estimates of monthly air filter demand and his monthly air filter production cost (in cents).

Lance can use the current month’s production to meet the current month’s demand. If he holds air filters at the end of a month he will incur a holding cost of 2 cents/air filter/month. Due to space restrictions, no more than 50 air filters can be held at a time. For outsourcing, Lance has contracted with a Canadian supplier who will sell Lance air filters at a constant price of 5 cents per filter at any time during the year. For quality assurance, Lance and Corin determined that no more than 10% of total filter demand should be met with outsourced filters.

Determine the Lance’s minimum cost production schedule for the year, i.e., how many filters should he produce each month, how many should he obtain from Canada each month, and how many should he store each month?

Month Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Demand 100 110 60 70 110 110 120 80 50 60 80 110 Cost of 6 2 5 5 5 7 4 5 3 6 6 Production

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started