Answered step by step

Verified Expert Solution

Question

1 Approved Answer

In arena, just the modules used 5-9 Parts arrive at a machine shop with EXPO(25) interarrival times (all times are in minutes); the first part

In arena, just the modules used

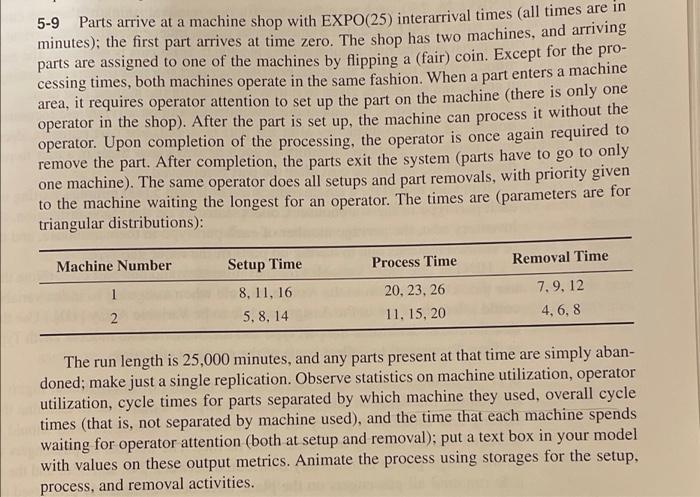

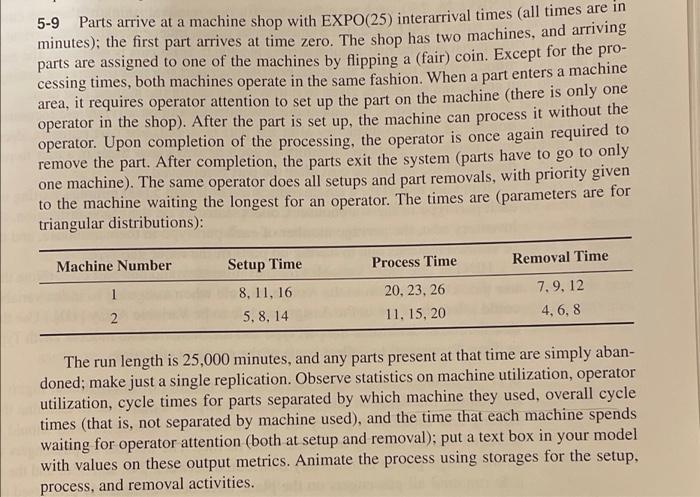

5-9 Parts arrive at a machine shop with EXPO(25) interarrival times (all times are in minutes); the first part arrives at time zero. The shop has two machines, and arriving parts are assigned to one of the machines by flipping a (fair) coin. Except for the pro- cessing times, both machines operate in the same fashion. When a part enters a machine area, it requires operator attention to set up the part on the machine (there is only one operator in the shop). After the part is set up, the machine can process it without the operator. Upon completion of the processing, the operator is once again required to remove the part. After completion, the parts exit the system (parts have to go to only one machine). The same operator does all setups and part removals, with priority given to the machine waiting the longest for an operator. The times are (parameters are for triangular distributions): Machine Number Removal Time Setup Time Process Time 1 8, 11, 16 5, 8, 14 20, 23, 26 11.15, 20 7,9,12 4,6,8 2 The run length is 25,000 minutes, and any parts present at that time are simply aban- doned; make just a single replication. Observe statistics on machine utilization, operator utilization, cycle times for parts separated by which machine they used, overall cycle times (that is, not separated by machine used), and the time that each machine spends waiting for operator attention (both at setup and removal): put a text box in your model with values on these output metrics. Animate the process using storages for the setup. process, and removal activities. 5-9 Parts arrive at a machine shop with EXPO(25) interarrival times (all times are in minutes); the first part arrives at time zero. The shop has two machines, and arriving parts are assigned to one of the machines by flipping a (fair) coin. Except for the pro- cessing times, both machines operate in the same fashion. When a part enters a machine area, it requires operator attention to set up the part on the machine (there is only one operator in the shop). After the part is set up, the machine can process it without the operator. Upon completion of the processing, the operator is once again required to remove the part. After completion, the parts exit the system (parts have to go to only one machine). The same operator does all setups and part removals, with priority given to the machine waiting the longest for an operator. The times are (parameters are for triangular distributions): Machine Number Removal Time Setup Time Process Time 1 8, 11, 16 5, 8, 14 20, 23, 26 11.15, 20 7,9,12 4,6,8 2 The run length is 25,000 minutes, and any parts present at that time are simply aban- doned; make just a single replication. Observe statistics on machine utilization, operator utilization, cycle times for parts separated by which machine they used, overall cycle times (that is, not separated by machine used), and the time that each machine spends waiting for operator attention (both at setup and removal): put a text box in your model with values on these output metrics. Animate the process using storages for the setup. process, and removal activities

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started