Question

In January 2001, Mary Linn, Vice President of Finance for Ocean Carriers, a shipping company with offices in New York and Hong Kong, was evaluating

In January 2001, Mary Linn, Vice President of Finance for Ocean Carriers, a shipping company with offices in New York and Hong Kong, was evaluating a proposed lease of a ship for a three-year period, beginning in early 2003. The customer was eager to finalize the contract to meet his own commitments and offered very attractive terms. No ship in Ocean Carriers current fleet met the customers requirements. Linn, therefore, had to decide whether Ocean Carriers should immediately commission a new capesize carrier that would be completed two years hence and could be leased to the customer.

Ocean Carriers Inc. owned and operated capesize dry bulk carriers that mainly carried iron ore worldwide. This type of vessel ranged in size from 80,000 deadweight tons to 210,000 deadweight tons of cargo carrying capacity. Capesize carriers were too large to transit the Panama Canal and therefore had to sail around Cape Horn to travel between the Atlantic and Pacific Oceans. In January 2001, there were 553 capesizes in service in the world.

Ocean Carriers vessels were mostly chartered on a time charter basis for a period such as one year, three years, or five years, although the spot charter market was used on occasion. The company that chartered the ship was called the charterer. The charterer paid Ocean Carriers a daily hire rate for the entire length of the contract, determined what cargo the vessel carried, and controlled where the vessel loaded and unloaded. The company, in turn, supplied a seaworthy vessel that complied with international regulations and manned the vessel with a fully qualified and certified crew.

Ship Operations

Operations also included ensuring adequate supplies and stores were onboard, supplying lubricating oils, scheduling repairs, conducting overall maintenance of the vessel, and placing all insurances for the vessel. For a new ship coming on line in early 2003, operating costs were expected to initially average $4,000 per day, and to increase annually at a rate of 1% above inflation. Charterers were not charged a daily rate for the time the vessel spent in maintenance and repair, although operating costs were still incurred. Initially, 8 days a year were scheduled for such work. The time allotted to maintenance and repairs increased to 12 days per year after five years of operation, and to 16 days a year for ships older than ten years.

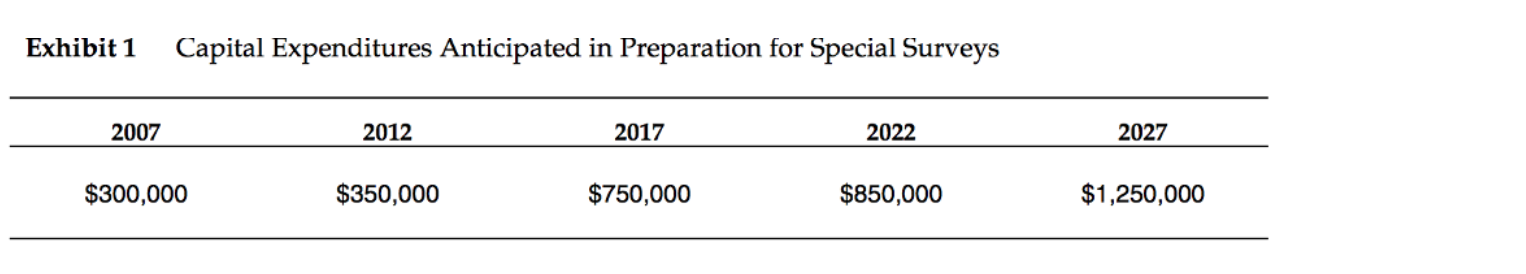

The company had a policy of not operating vessels older than 15 years. Every five years, international regulations mandated that a special survey be undertaken to ensure seaworthiness as defined by international regulations. By the fifteenth year, the maintenance required to comply with the special surveys was very costly. Exhibit 1 shows the capital expenditures anticipated in preparation for the special surveys. These outlays were considered capital expenditures, which would each be depreciated on a straight-line basis over a 5-year period. To avoid the larger expenditures for older ships, the company planned to sell the vessel into the secondhand market, or scrap the vessel just before the third special survey. When scrapped, the vessel was demolished and its steel was sold to demolition yards. The company estimated the scrap value to be $5M at the end of the fifteenth year.

Supply of Capesizes

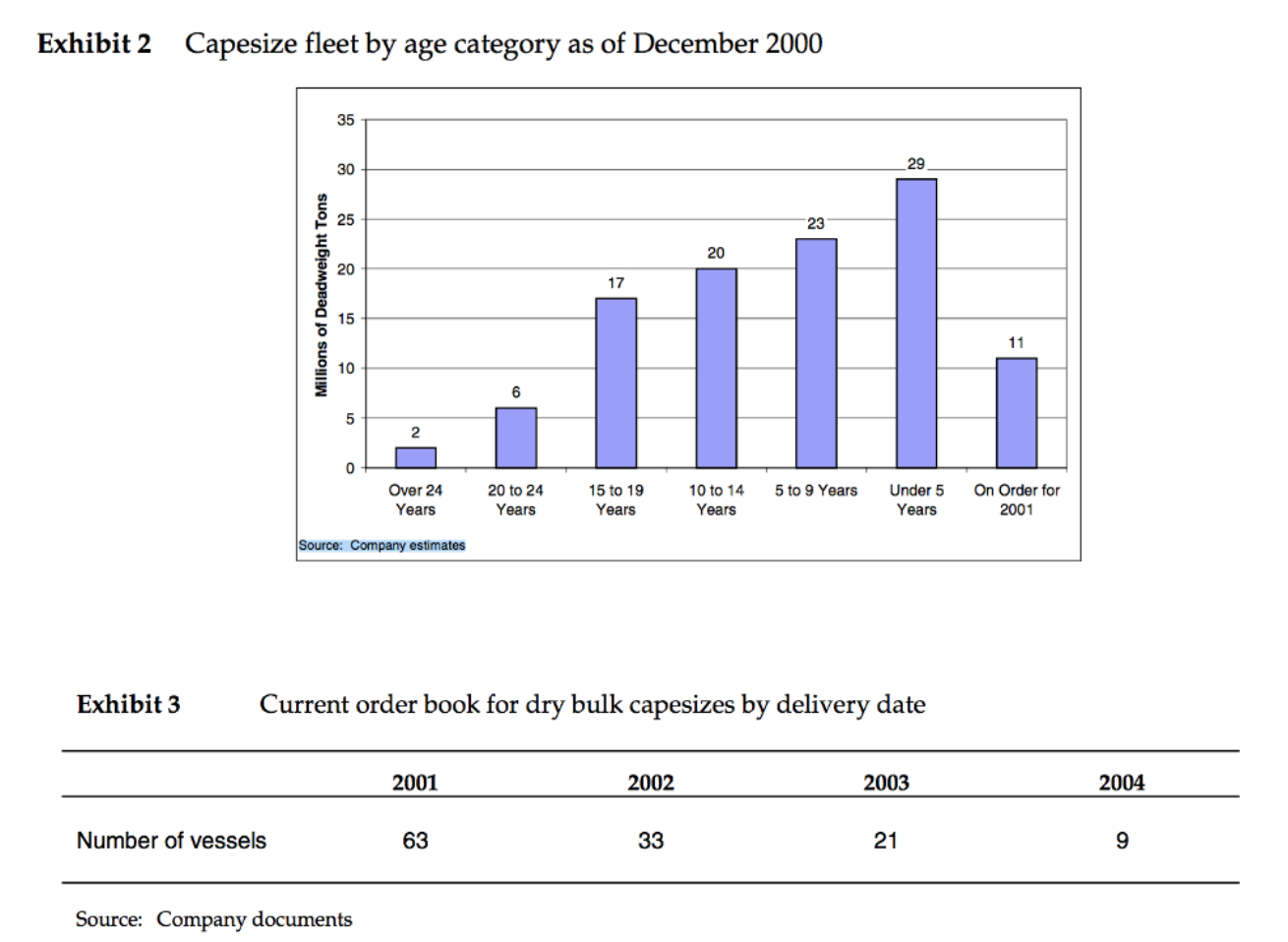

Daily hire rates were determined by supply and demand. The number of ships available equaled the number of vessels in service the previous year plus any new ships delivered minus any scrappings and sinkings. When the market demand for shipping capacity was high, owners would keep a vessel in operation as long as possible. Conversely, when market demand was low, scrapping rose. Supply was also affected by the increases in size and efficiency the newer ships offered. As ships got bigger, faster, and more fuel efficient, fewer ships were needed to carry the same amount of cargo. Moreover, there had been very few scrappings in recent years, and most of the capacity of the worldwide fleet of capesizes was fairly young. Exhibit 2 shows the capesize fleet by age category as of December 2000. Exhibit 3 shows the number of new capesize vessels by expected delivery date.

Exhibit 2 Capesize fleet by age category as of December 2000

Estimates of future orders for vessels were not entirely reliable, especially projections spanning more than two or three years in the future. If sentiment was optimistic on market conditions, more vessels would be added to the order book. If the market outlook was poor, then vessels would be cancelled or converted to other types of vessels. A capesize took approximately 10 months to build, but contracts were signed to secure a berth place approximately two years before delivery and over one year before steel cutting for the vessel. Delivery referred to when the vessel was complete and delivered from the shipyard to the owner.

Market conditions

The demand for dry bulk capesizes was determined by the world economy, especially its basic industries. Over 85% of the cargo carried by capesizes was iron ore and coal. Production and demand for these products increased in a strong economy. Changes in trade patterns also affected the demand for capesizes. For example, if a Western European country decided to switch its supply of iron ore from the United States to Australia, the demand for capesizes would increase since the distance between Europe and Australia is greater than the distance between Western Europe and the United States.

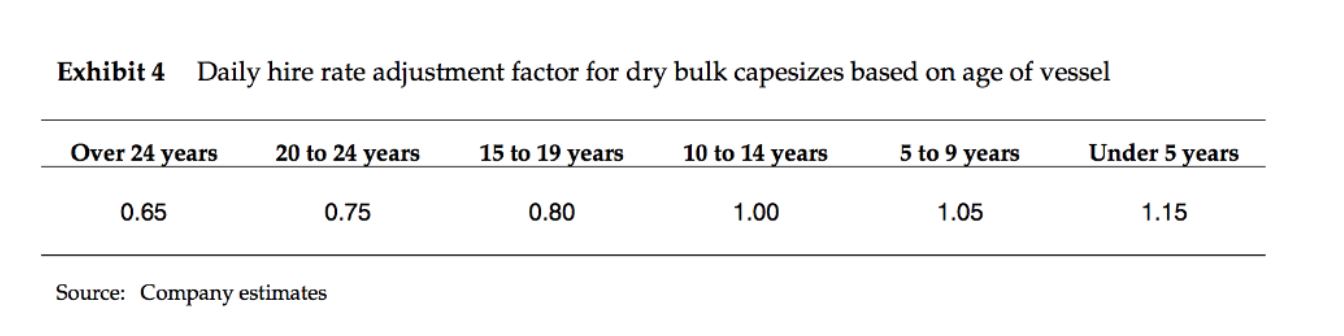

Spot charter rates tended to fluctuate more widely than time charter rates, i.e., the highs were higher and the lows were lower in the spot market. Therefore, when the market was high, ship owners sought time charters to lock in the high rates for as long a period as possible while the charterers preferred to trade in the spot market to avoid having to pay high daily rates any longer than necessary. Because Ocean Carriers vessels were relatively new and a bit larger than the industry average, they earned a premium to the market. For example, new ships generally earned a 15% premium in daily hire rates relative to the industry-wide average, while ships over 25 years old typically received a 35% discount from the industry average. Exhibit 4 shows average adjustments to daily hire rates for 3-year time charters based on the age of the ship.

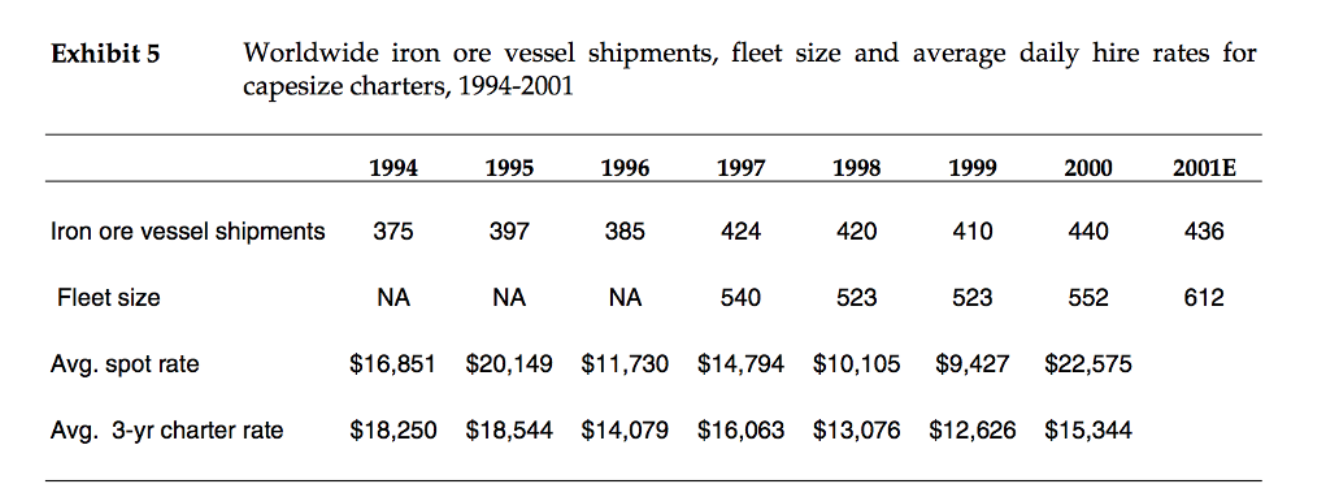

The average prevailing spot market rate at the time was $22,000 per day.1 With Australian production in iron ore expected to be strong and Indian iron ore exports expected to take off in the next few years, Linn took an optimistic view of the long-term market demand for capesizes. However, she also considered that 63 new vessels were scheduled for delivery in 2001 and that imports of iron ore and coal would probably remain stagnant over the next two years. Linn therefore anticipated that spot rates would fall in 2001 and 2002. In 2003, however, Linn was aware that Australian and Indian ore exports would begin, and that these new supplies would significantly increase trading volumes. Demand for capesizes would likely increase with these higher trading volumes, possibly boosting prices. Exhibit 5 provides data on some demand drivers, fleet size, and average daily hire rates over time.

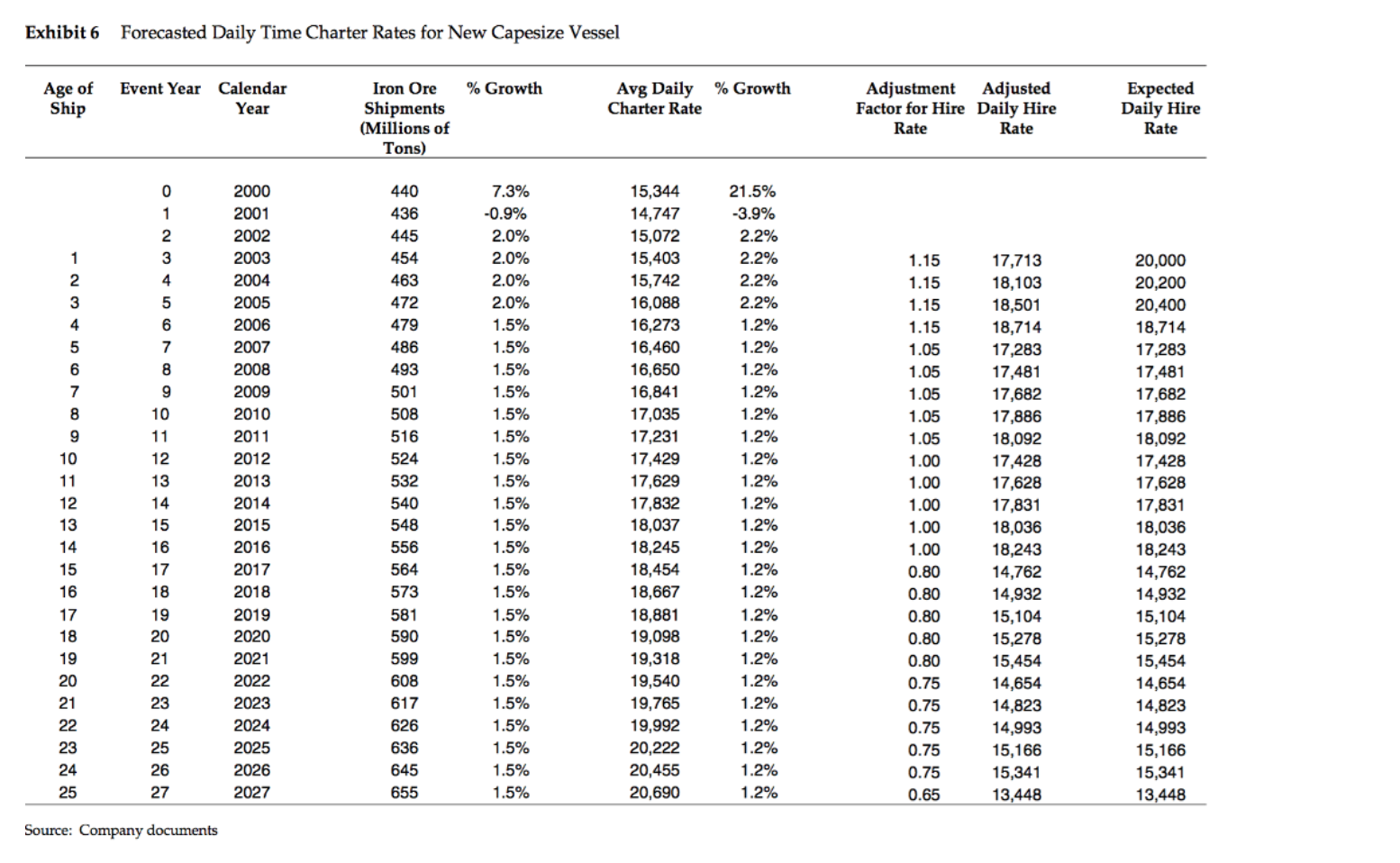

Linn enlisted the services of a shipping-industry consulting firm to help her forecast daily hire rates for a new capesize. Worldwide iron ore vessel shipments and charter rates had been very strongly associated historically. The consulting group felt that this relation would continue to hold in the future, and based its forecast of charter rates off of long-term forecasts for worldwide iron ore vessel shipments. The long-term forecast for worldwide iron ore vessel shipments was for 2% annual growth during 2002 to 2005, and then dropping to 1.5% thereafter. Exhibit 6 shows the forecast of daily hire rates that was prepared for Linn.

Newbuilding

The charterer currently in negotiations with Ocean Carriers for a three-year time charter starting in 2003 had offered a rate of $20,000 per day with an annual escalation of $200 per day. The expected rate of inflation was 3%.

The vessels in Ocean Carriers current fleet could not be committed to a time charter beginning in 2003 because the ships were either already leased during that period or were too small to meet the customers needs. Moreover, there were no sufficiently large capesizes available in the second-hand market. Ocean Carriers had to decide immediately if it should commission a new 180,000 deadweight ton ship for delivery in early 2003. The ship would cost $39 million, with 10% of the purchase price payable immediately and 10% due in a years time. The balance would be due on delivery. A new ship would be depreciated on a straight-line basis over 25 years. In addition, Linn expected to make a $500,000 initial investment in net working capital, which she anticipated would grow with inflation.

Linn was also confident that the charterer would honor his proposed contract with Ocean Carriers if the company agreed to the terms. While there is always a risk that the charterer would stop paying before the end of the contract or terminate the contract early, Linn considered that the risk was small. Ocean Carriers had long established relationships with its charterers and only contracted with reputable charterers.

The proposed contract, though, was only for three years, and it was Linns responsibility to decide if future market conditions warranted the considerable investment in a new ship.

Ocean Carriers uses a 9% discount rate.

- Do you expect daily spot hire rates to increase or decrease next year?

- What factors drive average daily hire rates?

- How would you characterize the long-term prospects of the capesize dry bulk industry?

- Should Ms. Linn purchase the $39M capesize? Make two different assumptions. First, assume that Ocean Carriers is a U.S. firm subject to 35% taxation. Second, assume that Ocean Carriers is located in Hong Kong, where owners of Hong Kong ships are not required to pay any tax on profits made overseas and are also exempted from paying any tax on profit made on cargo uplifted from Hong Kong.

- What do you think of the companys policy of not operating ships over 15 years old?

- Create and submit an Excel model your team used for FCF and NPV calculations. Grading will be based on a) good organization of spreadsheet layout and b) correct formula for every calculated cell.

Very confused on how to solve in excel in terms of formulas.

Exhibit 1 Capital Expenditures Anticipated in Preparation for Special Surveys 2007 2012 2017 2022 2027 $300,000 $350,000 $750,000 $850,000 $1,250,000 Exhibit 2 Capesize fleet by age category as of December 2000 35 30 29 25 23 20 20 17 Millions of Deadweight Tons 15 11 10 6 5 2 0 5 to 9 Years Under 5 Over 24 Years 20 to 24 Years 15 to 19 Years 10 to 14 Years Years On Order for 2001 Source: Company estimates Exhibit 3 Current order book for dry bulk capesizes by delivery date 2001 2002 2003 2004 Number of vessels 63 33 21 9 Source: Company documents Exhibit 4 Daily hire rate adjustment factor for dry bulk capesizes based on age of vessel Over 24 years 20 to 24 years 15 to 19 years 10 to 14 years 5 to 9 years Under 5 years 0.65 0.75 0.80 1.00 1.05 1.15 Source: Company estimates Exhibit 5 Worldwide iron ore vessel shipments, fleet size and average daily hire rates for capesize charters, 1994-2001 1994 1995 1996 1997 1998 1999 2000 2001E Iron ore vessel shipments 375 397 385 424 420 410 440 436 Fleet size NA NA NA 540 523 523 552 612 Avg. spot rate $16,851 $20,149 $11,730 $14,794 $10,105 $9,427 $22,575 Avg. 3-yr charter rate $18,250 $18,544 $14,079 $16,063 $13,076 $12,626 $15,344 Exhibit 6 Forecasted Daily Time Charter Rates for New Capesize Vessel Event Year Calendar Year % Growth Age of Ship % Growth Avg Daily Charter Rate Iron Ore Shipments (Millions of Tons) Adjustment Adjusted Factor for Hire Daily Hire Rate Rate Expected Daily Hire Rate 440 436 445 454 463 1 2 3 4 5 472 479 486 6 7 493 501 508 516 8 9 10 11 524 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 2022 2023 2024 2025 2026 2027 7.3% -0.9% 2.0% 2.0% 2.0% 2.0% 1.5% 1.5% 1.5% 1.5% 1.5% 1.5% 1.5% 1.5% 1.5% 1.5% 1.5% 1.5% 1.5% 1.5% 1.5% 1.5% 1.5% 1.5% 1.5% 1.5% 1.5% 1.5% 15,344 14,747 15,072 15,403 15,742 16,088 16,273 16,460 16,650 16,841 17,035 17,231 17,429 17,629 17,832 18,037 18,245 18,454 18,667 18,881 19,098 19,318 19,540 19,765 19,992 20,222 20,455 20,690 21.5% -3.9% 2.2% 2.2% 2.2% 2.2% 1.2% 1.2% 1.2% 1.2% 1.2% 1.2% 1.2% 1.2% 1.2% 1.2% 1.2% 1.2% 1.2% 1.2% 1.2% 1.2% 1.2% 1.2% 1.2% 1.2% 1.2% 1.2% 532 540 548 556 564 573 581 590 599 608 12 13 1.15 1.15 1.15 1.15 1.05 1.05 1.05 1.05 1.05 1.00 1.00 1.00 1.00 1.00 0.80 0.80 0.80 0.80 0.80 0.75 0.75 0.75 0.75 0.75 0.65 17,713 18,103 18,501 18,714 17,283 17,481 17,682 17,886 18,092 17,428 17,628 17,831 18,036 18,243 14,762 14,932 15,104 15,278 15,454 14,654 14,823 14,993 15,166 15,341 13,448 20,000 20,200 20,400 18,714 17,283 17,481 17,682 17,886 18,092 17,428 17,628 17,831 18,036 18,243 14,762 14,932 15,104 15,278 15,454 14,654 14,823 14,993 15,166 15,341 13,448 14 15 16 17 18 617 19 20 21 22 23 24 25 626 636 645 655 Source: Company documentsStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started