Answered step by step

Verified Expert Solution

Question

1 Approved Answer

In mid-January of 2016, Melissa Brown, president of BonaVista Pools Limited (BonaVista), and Peter Brown, vice-president of BonaVista, met at their office in Toronto,

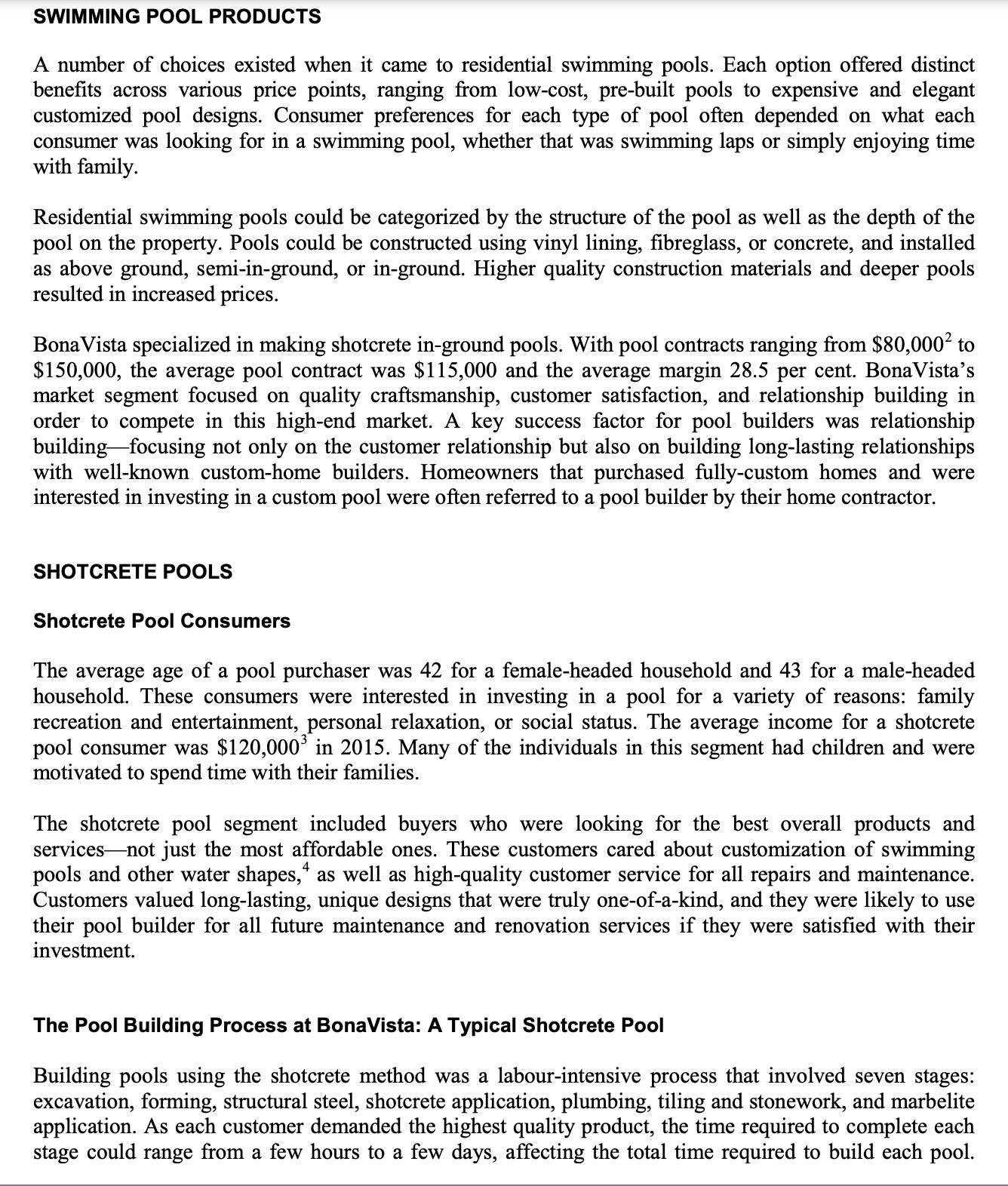

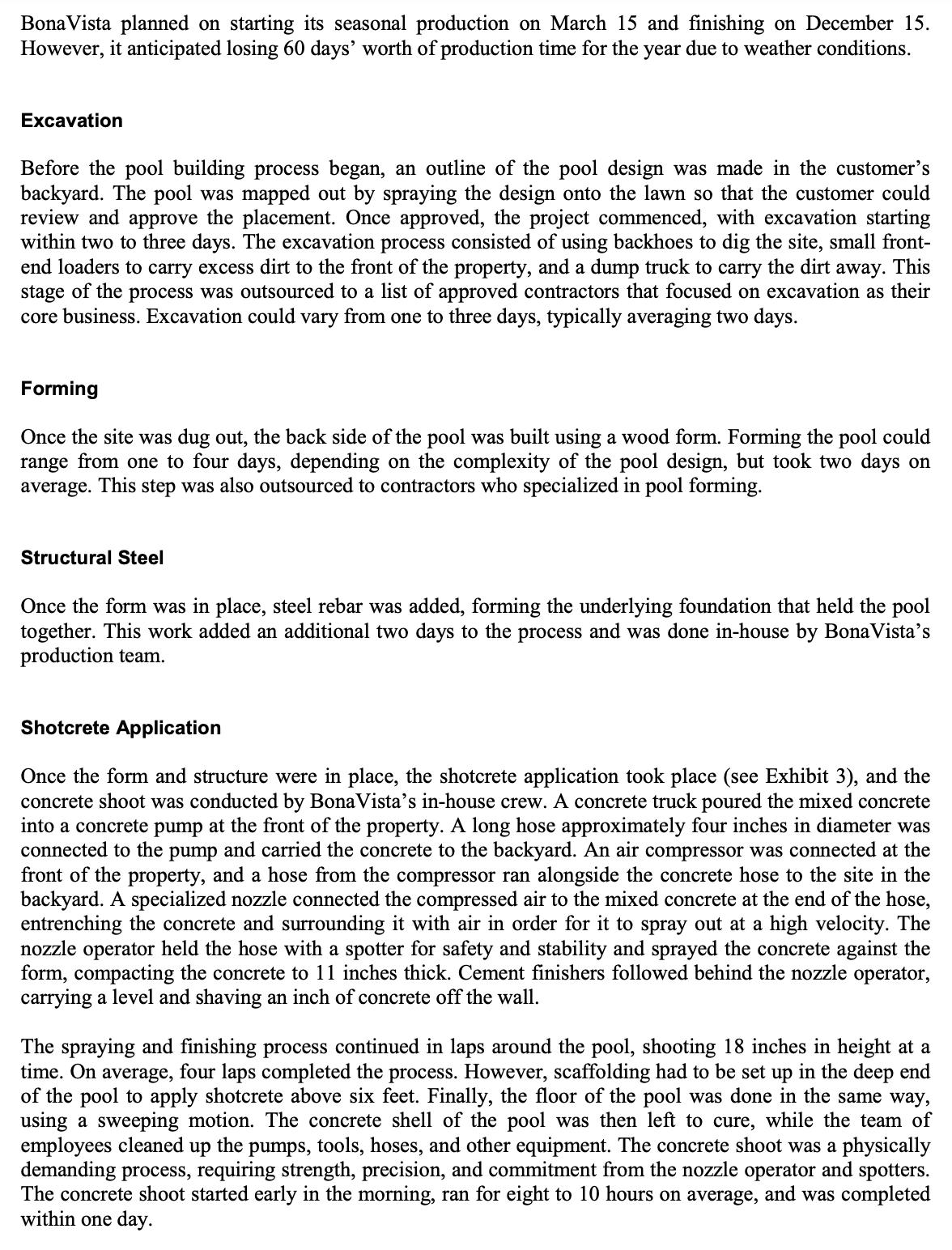

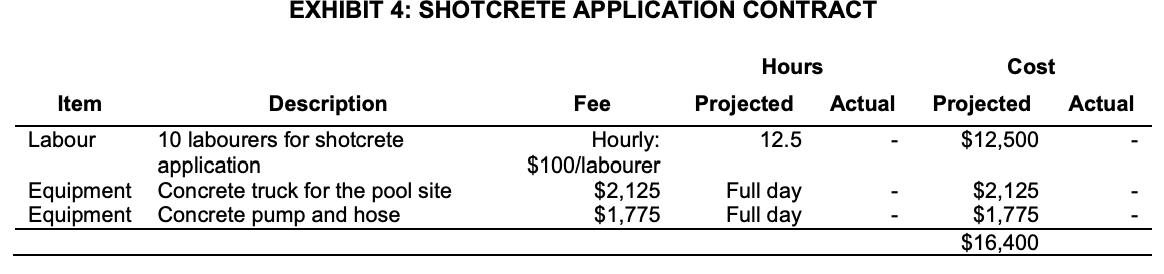

In mid-January of 2016, Melissa Brown, president of BonaVista Pools Limited (BonaVista), and Peter Brown, vice-president of BonaVista, met at their office in Toronto, Ontario, to discuss plans for the upcoming production season. Earlier that month, Melissa and Peter had received notice that their senior nozzle operator would be resigning to start a new career and that their second senior nozzle operator was injured and unable to work for the upcoming season. BonaVista was faced with the absence of their two most highly-trained employees, who oversaw an extremely important step in the pool production process. Anticipating a busy season, Melissa and Peter knew they needed to make a decision soon about how to handle the loss of their two senior nozzle operators. BONAVISTA POOLS Bona Vista was founded in 1969 under the name ValMar Toronto, a subsidiary of ValMar Pools in Montreal. At the time, Ken Valois, president of ValMar Pools, had tasked his cousin, Bob Brown, with managing the Toronto branch of the company. From 1969 to 1978, ValMar Toronto installed over 1,000 pools within the Greater Toronto Area (GTA). Bob was confident that this was just the beginning of the company's growth within the region and decided to purchase ValMar's Toronto operations in 1979. Bob renamed the business BonaVista Pools, and phased out the ValMar brand by 1982. From that point forward, the business ran under Bob's management and vision (see Exhibit 1). When Bob took over, the core focus of the business was to build shotcrete swimming pools. Over the years, BonaVista developed a much more customized, high-end pool design-build process (see Exhibit 2). The business grew to include a service department and retail sales team in the GTA, with approximately 85 per cent of BonaVista's sales being within two hours of the downtown Toronto area. All five of Bob's children grew up working in the business in some way, and ultimately his daughter Melissa (P.Eng and EMBA from the Ivey Business School) and son Peter (BBA) chose to take over when Bob retired in 2002. By that time, BonaVista was well known in the GTA as a premier, custom concrete- pool builder and service provider, a reputation it still currently enjoyed. 1 A mixture of cement, sand, and water applied through a pressure hose, producing a dense hard layer of concrete. SWIMMING POOL PRODUCTS A number of choices existed when it came to residential swimming pools. Each option offered distinct benefits across various price points, ranging from low-cost, pre-built pools to expensive and elegant customized pool designs. Consumer preferences for each type of pool often depended on what each consumer was looking for in a swimming pool, whether that was swimming laps or simply enjoying time with family. Residential swimming pools could be categorized by the structure of the pool as well as the depth of the pool on the property. Pools could be constructed using vinyl lining, fibreglass, or concrete, and installed as above ground, semi-in-ground, or in-ground. Higher quality construction materials and deeper pools resulted in increased prices. Bona Vista specialized in making shotcrete in-ground pools. With pool contracts ranging from $80,000 to $150,000, the average pool contract was $115,000 and the average margin 28.5 per cent. BonaVista's market segment focused on quality craftsmanship, customer satisfaction, and relationship building in order to compete in this high-end market. A key success factor for pool builders was relationship building focusing not only on the customer relationship but also on building long-lasting relationships with well-known custom-home builders. Homeowners that purchased fully-custom homes and were interested in investing in a custom pool were often referred to a pool builder by their home contractor. SHOTCRETE POOLS Shotcrete Pool Consumers The average age of a pool purchaser was 42 for a female-headed household and 43 for a male-headed household. These consumers were interested in investing in a pool for a variety of reasons: family recreation and entertainment, personal relaxation, or social status. The average income for a shotcrete pool consumer was $120,000 in 2015. Many of the individuals in this segment had children and were motivated to spend time with their families. 4 The shotcrete pool segment included buyers who were looking for the best overall products and services not just the most affordable ones. These customers cared about customization of swimming pools and other water shapes, as well as high-quality customer service for all repairs and maintenance. Customers valued long-lasting, unique designs that were truly one-of-a-kind, and they were likely to use their pool builder for all future maintenance and renovation services if they were satisfied with their investment. The Pool Building Process at BonaVista: A Typical Shotcrete Pool Building pools using the shotcrete method was a labour-intensive process that involved seven stages: excavation, forming, structural steel, shotcrete application, plumbing, tiling and stonework, and marbelite application. As each customer demanded the highest quality product, the time required to complete each stage could range from a few hours to a few days, affecting the total time required to build each pool. BonaVista planned on starting its seasonal production on March 15 and finishing on December 15. However, it anticipated losing 60 days' worth of production time for the year due to weather conditions. Excavation Before the pool building process began, an outline of the pool design was made in the customer's backyard. The pool was mapped out by spraying the design onto the lawn so that the customer could review and approve the placement. Once approved, the project commenced, with excavation starting within two to three days. The excavation process consisted of using backhoes to dig the site, small front- end loaders to carry excess dirt to the front of the property, and a dump truck to carry the dirt away. This stage of the process was outsourced to a list of approved contractors that focused on excavation as their core business. Excavation could vary from one to three days, typically averaging two days. Forming Once the site was dug out, the back side of the pool was built using a wood form. Forming the pool could range from one to four days, depending on the complexity of the pool design, but took two days on average. This step was also outsourced to contractors who specialized in pool forming. Structural Steel Once the form was in place, steel rebar was added, forming the underlying foundation that held the pool together. This work added an additional two days to the process and was done in-house by BonaVista's production team. Shotcrete Application Once the form and structure were in place, the shotcrete application took place (see Exhibit 3), and the concrete shoot was conducted by BonaVista's in-house crew. A concrete truck poured the mixed concrete into a concrete pump at the front of the property. A long hose approximately four inches in diameter was connected to the pump and carried the concrete to the backyard. An air compressor was connected at the front of the property, and a hose from the compressor ran alongside the concrete hose to the site in the backyard. A specialized nozzle connected the compressed air to the mixed concrete at the end of the hose, entrenching the concrete and surrounding it with air in order for it to spray out at a high velocity. The nozzle operator held the hose with a spotter for safety and stability and sprayed the concrete against the form, compacting the concrete to 11 inches thick. Cement finishers followed behind the nozzle operator, carrying a level and shaving an inch of concrete off the wall. The spraying and finishing process continued in laps around the pool, shooting 18 inches in height at a time. On average, four laps completed the process. However, scaffolding had to be set up in the deep end of the pool to apply shotcrete above six feet. Finally, the floor of the pool was done in the same way, using a sweeping motion. The concrete shell of the pool was then left to cure, while the team of employees cleaned up the pumps, tools, hoses, and other equipment. The concrete shoot was a physically demanding process, requiring strength, precision, and commitment from the nozzle operator and spotters. The concrete shoot started early in the morning, ran for eight to 10 hours on average, and was completed within one day. Plumbing Once the pool was constructed, the plumbing was installed underground. Following this, the mechanical equipment, consisting of the pool pump and filter, was installed. The plumbing and mechanical equipment installation was done by BonaVista's team and usually took one day on average to complete. Tiling and Stonework Waterline tile was installed around the inside of the pool. BonaVista was hired to do the tile setting for approximately 90 per cent of the pools it built but outsourced this process to one of the two or three pre- approved tile setters, to reduce costs. A stonemason finished the stone coping around the pool. Since many of the elite projects BonaVista worked on usually involved an entire backyard remodel, BonaVista was hired to do the stone coping on only approximately 40 per cent of the pools it built. Therefore, due to the low frequency of stone coping jobs awarded to BonaVista, this process was also subcontracted out. Once the pool was almost complete, an electrician and a gas fitter installed the controls for the pool. BonaVista outsourced this process to certified electricians and gas fitters. Overall, waterline tiling and stonework added three days to the pool production process. Marbelite Application Marbelite application was the final step in the process. Marbelite was used to finish the rough concrete shell of the pool. The marbelite application was subcontracted out to a company that was able to complete at least one pool a day. Once the marbelite was applied, water was pumped into the pool to ensure that the application cured properly. ALTERNATIVES With the season starting soon and no dependable nozzle operator on BonaVista's crew to build pools, Melissa and Peter had three options: hire and train a new senior nozzle operator, train and promote their junior nozzle operator, or outsource the shotcrete application to another company. Hiring a New Senior Nozzle Operator A senior nozzle operator was considered to have at least five years of nozzle operator experience and to have undergone extensive training. This trade was considered a niche service, which made it difficult to find anyone with the necessary experience who was also searching for employment in the GTA. Senior nozzle operators earned an hourly wage of $24. Because of their experience, qualified senior nozzle operators were able to maintain the current pace of completing the shotcrete application process in one day. However, if a new senior nozzle operator were to be hired, there would be concerns about the quality of the shotcrete application and the new employee's fit within the organization. Shotcrete application required specific skills and expertise to ensure the pool was built with minimal structural weaknesses. Although a new nozzle operator may have had experience with shotcrete application, the process for shotcrete application in pools differed from the process for other structures. After the shoot was finished, the nozzle operator was responsible for assisting the team of employees in cleaning up the site, something that was not expected of a nozzle operator on other job sites. To ensure the operator had the required skills and was a good fit with the team, BonaVista planned to spend $1,000 for obtaining the services of a headhunting agency and $2,000 for training. Training and Promoting the Junior Nozzle Operator The current junior nozzle operator had been with BonaVista for three years and had experience assisting the senior nozzle operators as the spotter during shotcrete application. The junior nozzle operator was paid an hourly wage of $18 and worked approximately 40 hours per week. If BonaVista were to provide its junior nozzle operator with more specialized training, the projected cost was approximately $4,800 and a new hourly wage of $22 would be required. Although the junior nozzle operator showed strong potential, that operator's limited experience and lack of on-the-job training would require spending more time on the shotcrete application. Thus, by training and promoting the junior nozzle operator, BonaVista would finish the shotcrete application process in one and a half days when it should take only one day. One additional concern was the lack of backup for the company's new senior nozzle operator. Who would replace the junior nozzle operator, and what would be the alternative if the senior nozzle operator resigned or was unable to work? Outsourcing Opportunity Melissa and Peter also met with two shotcrete companies to discuss the possibility of outsourcing the shotcrete application process. Both companies were located within the GTA and had over 20 years of experience specializing in structural shotcrete lication. However, neither company had experience in shotcrete application for pool structures. This was a concern for BonaVista, as the shotcrete application was a core component of the pool structure. If the shotcrete process was not completed correctly, the pool's quality would be compromised. Since the process had always been done in-house, resource allocation and quality control had been managed internally. By outsourcing this process, BonaVista would be exposed to potential risks stemming from shooting delays and quality issues. One of the shotcrete companies provided BonaVista with a quote for a typical pool shoot (see Exhibit 4). If Bona Vista were to outsource this process, three general labourers from BonaVista would need to be on- site to ensure the shoot was meeting the specified requirements of the design. Each general labourer earned on average $16 per hour. BonaVista wondered about the financial implications of outsourcing the shotcrete process. Currently, it hired one in-house crew with six employees a senior nozzle operator who was paid $24 an hour, a junior nozzle operator who was paid $18 an hour, and four general labourers who were paid $16 an hour. The upside of outsourcing was that it simplified the operations of the business. The shotcrete application process was labour intensive and involved specific high-skilled labourers who were difficult to find and train. All of these operational and logistical issues would be the responsibility of the subcontractor. Item Labour EXHIBIT 4: SHOTCRETE APPLICATION CONTRACT Description 10 labourers for shotcrete application Equipment Concrete truck for the pool site Equipment Concrete pump and hose Fee Hourly: $100/labourer $2,125 $1,775 Hours Projected Actual 12.5 Full day Full day Cost Projected Actual $12,500 $2,125 $1,775 $16,400 10 11 3. Determine the current process that BonaVista Pools uses. Is it appropriate? How will the options impact this? 4 Determine production capacity if BonaVista hired a new senior nozzle operator. Perform a net benefit and payback analysis. Discuss the qualitative pros and cons of this proposed solution.

Step by Step Solution

★★★★★

3.41 Rating (154 Votes )

There are 3 Steps involved in it

Step: 1

Based on the information provided in the case study lets analyze BonaVista Pools current situation and how hiring a new senior nozzle operator may impact the business Current Process at BonaVista Pool...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started