Question

In service level agreements with customers, The Fresh Connection promises to deliver its products with the majority of shelf life still remaining, generally around 75%.

In service level agreements with customers, The Fresh Connection promises to deliver its products with the majority of shelf life still remaining, generally around 75%. This allows the customer to keep the product in stock for some time and guarantees consumers a decent shelf life period.

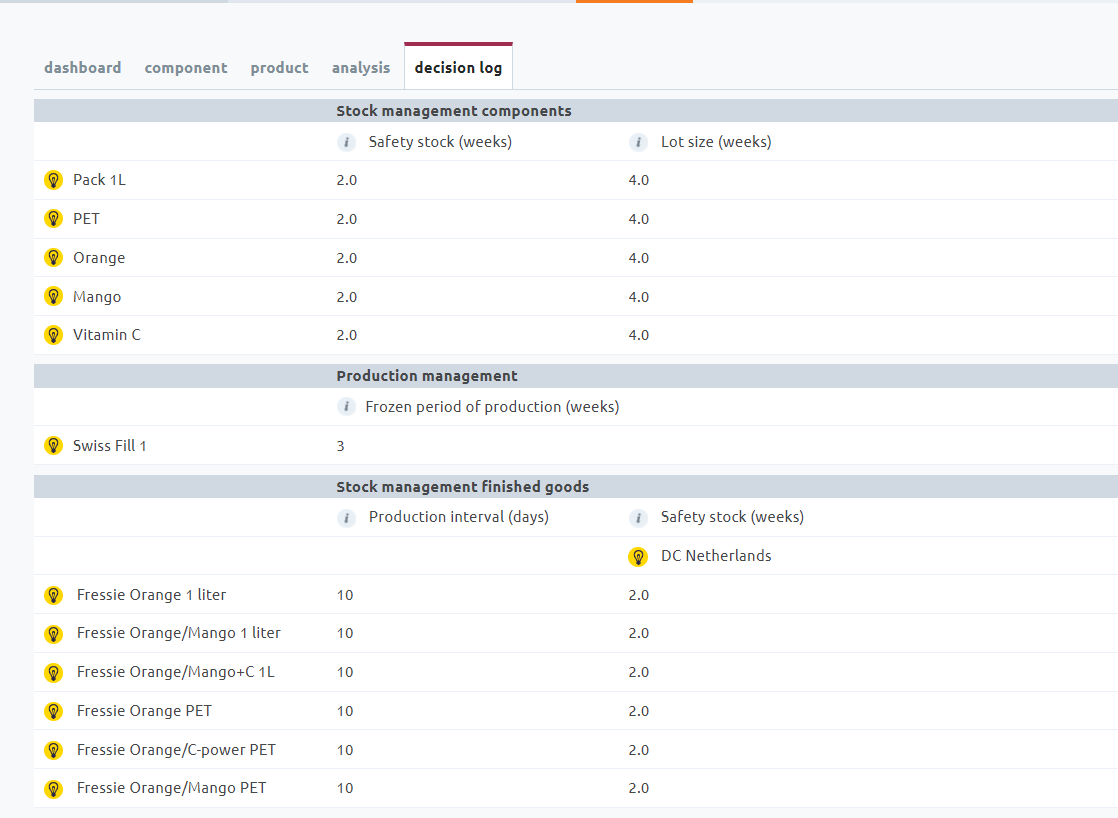

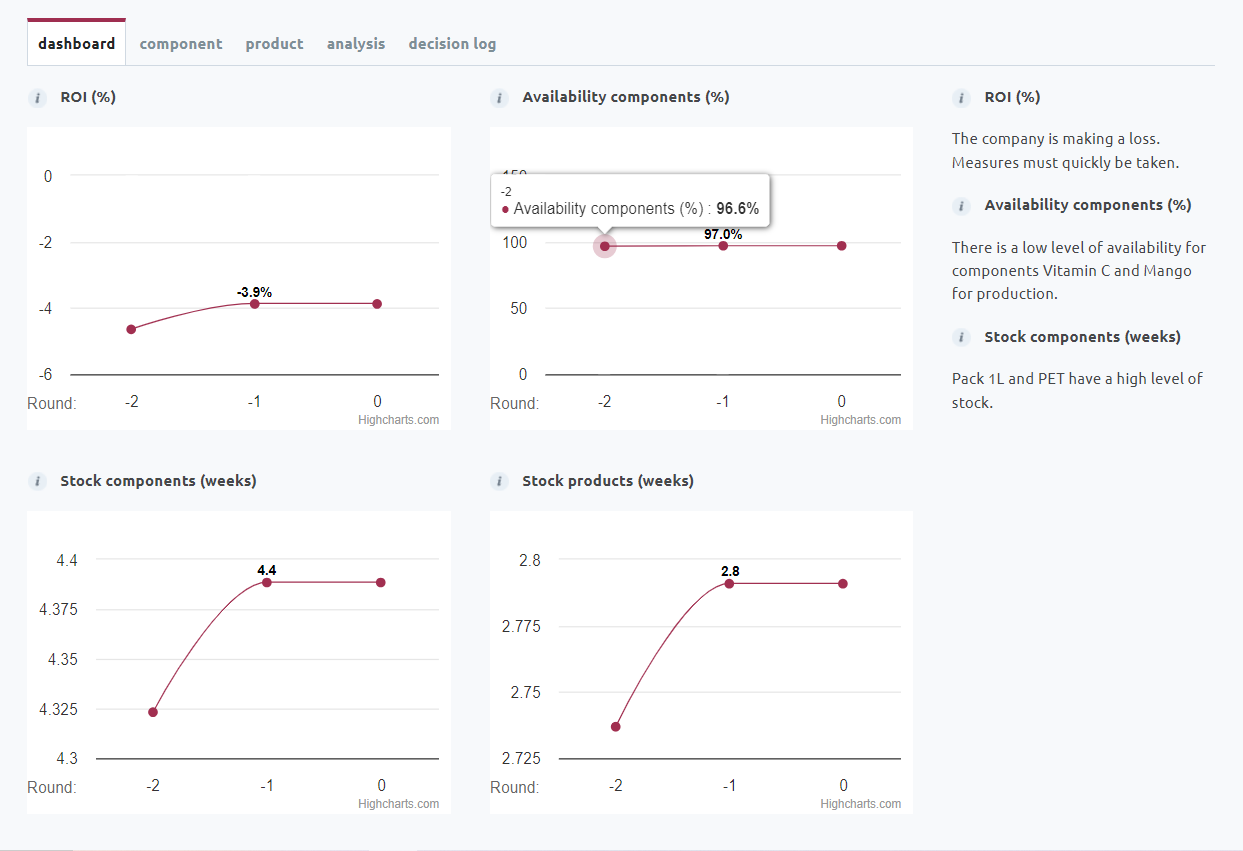

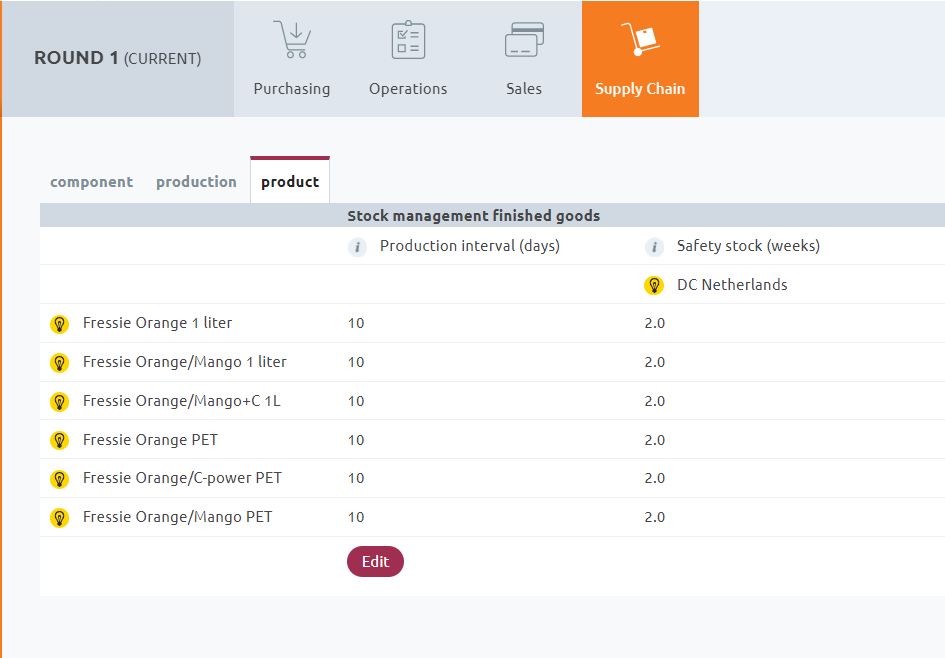

An example: a customer demands 75% of shelf life remaining, then only 25% of shelf life remains for The Fresh Connection. Suppose shelf life of a certain product is 20 weeks, this means that after production it can only remain in stock in The Fresh Connection's warehouse for at maximum 5 weeks (25% of 20 weeks). If it becomes older than 5 weeks, this customer will not accept it. The production interval is the number of working days between two production runs for the same finished product. If the production interval is 1, then the finished product is, produced every day, and if the production interval is 5, the finished product is produced once every week. The longer the production interval, the larger the production runs and the higher the average stock. And as with safety stocks, if inventory gets too high, this will cause obsolescence. Can anyone help on what decisions have to be made for changes from round 0 to Round 1. And why theses numbers changed. (Supply Chain Role) ROUND 0:

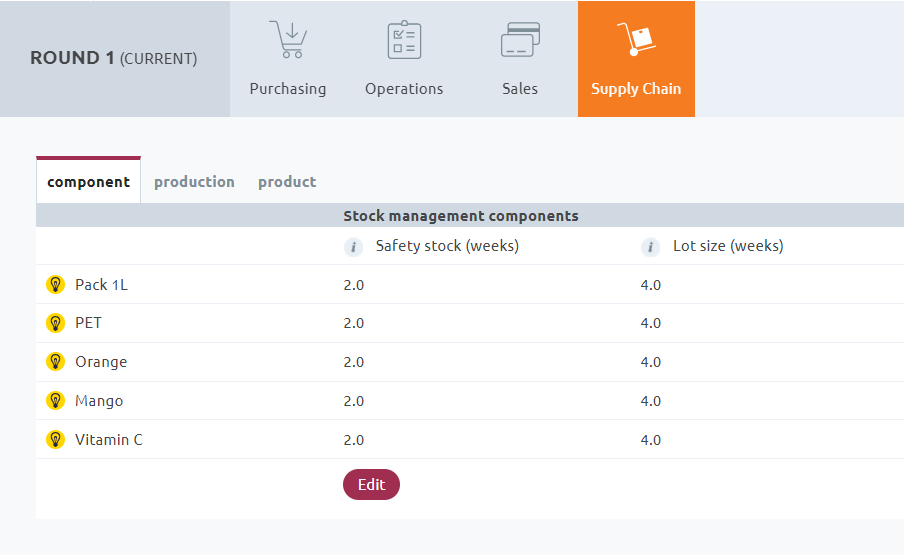

ROUND 1:

ROUND 1:

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started