Answered step by step

Verified Expert Solution

Question

1 Approved Answer

In the Fibertec case, you are analyzing 2 possible decisions- they are the traditional make or buy decisions that face firms. Analyze the differential case

-

In the Fibertec case, you are analyzing 2 possible decisions- they are the traditional make or buy decisions that face firms.

-

Analyze the differential case flows of the 2 options

-

What are the comparative impacts on people, clients/customers?

-

Based on all these things, what is your recommended approach?

-

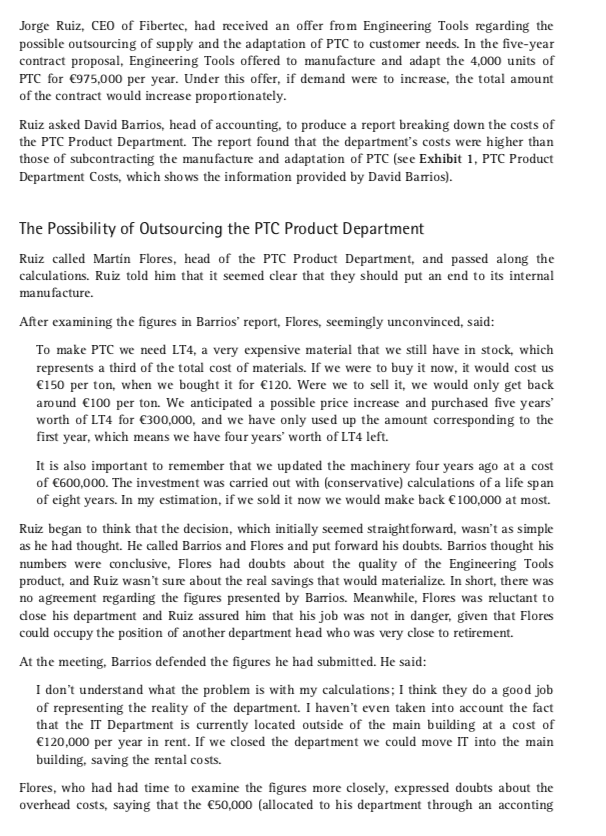

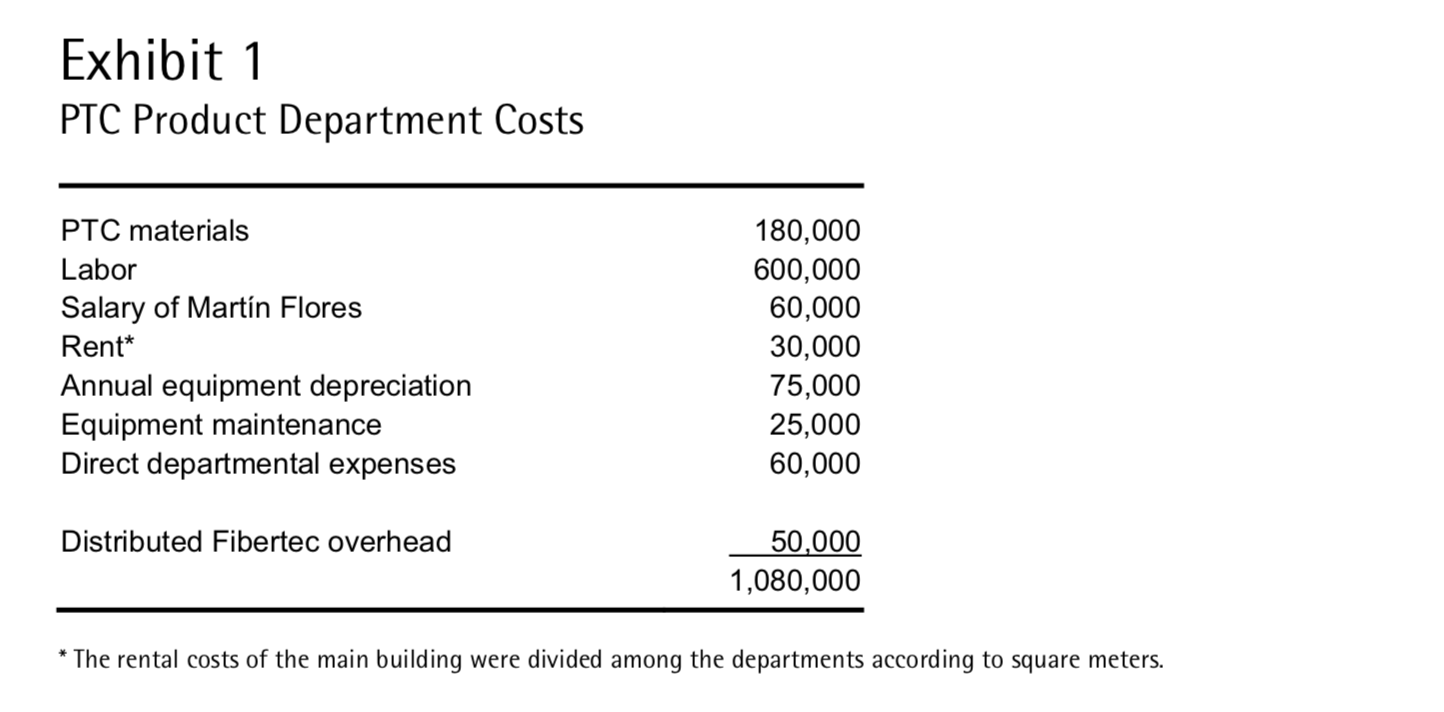

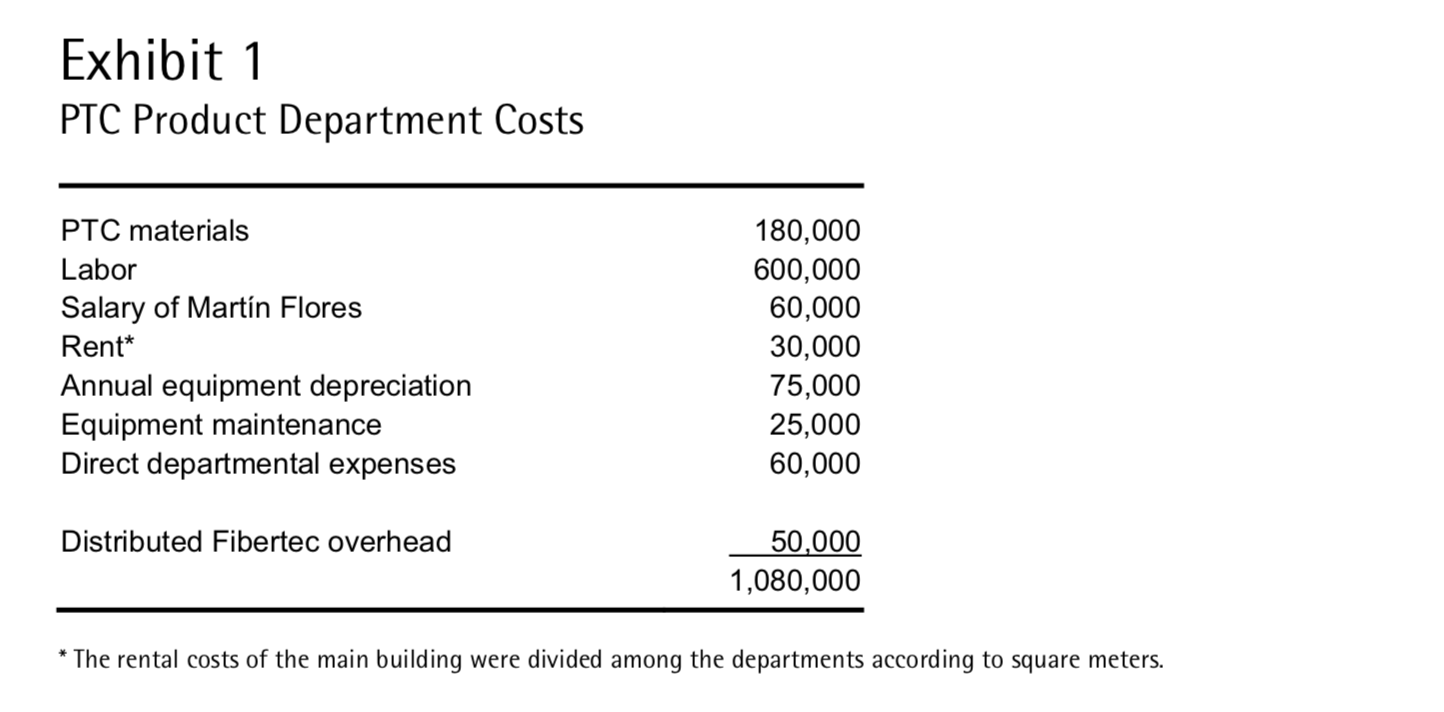

Fibertec Background Fibertec was a company that manufactured and processed a variety of natural products. It used highly advanced material processing technologies and had several departments engaged in the manufacture of numerous semi-finished products. The growing complexity of its products made the collaboration of engineering teams increasingly necessary. The Belgium-based company had a branch in Spain almost from the start. The Spanish office, which had six product departments, operated as a profit center that supplied its products globally. Its product strategy was fairly decentralized and it was able to make investment and disinvestment decisions on its own, requiring authorization from the head office in Belgium solely in the case of new product launches. Its clients had always been big industrial groups that used Fibertec products in their end products, such as in special storage containers and household and industrial textile products, among many others. The PTC Product Department From the very beginning, the PTC Product Department manufactured one of the company's leading products: PTC. At the time, it was considered to be a key product requested by many of its most important clients, and the company boasted about its particular skill in this area. However, this product did not generate especially high margins due to strong competitive pressure from alternative products. Jorge Ruiz, CEO of Fibertec, had received an offer from Engineering Tools regarding the possible outsourcing of supply and the adaptation of PTC to customer needs. In the five-year contract proposal, Engineering Tools offered to manufacture and adapt the 4,000 units of PTC for 975,000 per year. Under this offer, if demand were to increase, the total amount of the contract would increase proportionately. Ruiz asked David Barrios, head of accounting, to produce a report breaking down the costs of the PTC Product Department. The report found that the department's costs were higher than those of subcontracting the manufacture and adaptation of PTC (see Exhibit 1, PTC Product Department Costs, which shows the information provided by David Barrios). The Possibility of Outsourcing the PTC Product Department Ruiz called Martin Flores, head of the PTC Product Department, and passed along the calculations. Ruiz told him that it seemed clear that they should put an end to its internal manufacture. After examining the figures in Barrios' report, Flores, seemingly unconvinced, said: To make PTC we need LT4, a very expensive material that we still have in stock, which represents a third of the total cost of materials. If we were to buy it now, it would cost us 150 per ton, when we bought it for 120. Were we to sell it, we would only get back around 100 per ton. We anticipated a possible price increase and purchased five years' worth of LT4 for 300,000, and we have only used up the amount corresponding to the first year, which means we have four years' worth of LT4 left. It is also important to remember that we updated the machinery four years ago at a cost of 600,000. The investment was carried out with (conservative) calculations of a life span of eight years. In my estimation, if we sold it now we would make back 100,000 at Ruiz began to think that the decision, which initially seemed straightforward, wasn't as simple as he had thought. He called Barrios and Flores and put forward his doubts. Barrios thought his numbers were conclusive, Flores had doubts about the quality of the Engineering Tools product, and Ruiz wasn't sure about the real savings that would materialize. In short, there was no agreement regarding the figures presented by Barrios. Meanwhile, Flores was reluctant to dose his department and Ruiz assured him that his job was not in danger, given that Flores could occupy the position of another department head who was very close to retirement. At the meeting, Barrios defended the figures he had submitted. He said: I don't understand what the problem is with my calculations; I think they do a good job of representing the reality of the department. I haven't even taken into account the fact that the IT Department is currently located outside of the main building at a cost of 120,000 per year in rent. If we closed the department we could move IT into the main building, saving the rental costs. Flores, who had had time to examine the figures more closely, expressed doubts about the overhead costs, saying that the 50,000 (allocated to his department through an acconting Fibertec C-760 procedure) would not represent real savings for the company since it would not involve any reduction in costs. The most important thing to Flores, however, was his team. He was particularly worried about those who had been with the company the longest. Some employees were close to retirement age, but others, who had been with Fibertec for over 20 years, were of ages that would make it difficult to be hired by another company. What's more, they sometimes helped out with engineering tasks in other departments, though these departments paid the corresponding part of their wages. Flores thought that this aspect should not be considered in the decision. Finally, Flores said he didn't see where Barrios had included the severance pay that would have to be paid in the event of terminating the contracts of the department's employees. Barrios nodded and provided information on the delicate subject: "The total cost of the severance pay amounts to 660,000. Even though this is the amount calculated according to the law, we would probably have difficult negotiations with the unions about the subject" The Decision Ruiz was glad that he had included Flores in the deliberation, who, with a more realistic knowledge of the situation, had provided a very specific and pragmatic vision. He now had to decide, with the available options and estimates, what the best decision for Fibertec was. Exhibit 1 PTC Product Department Costs PTC materials Labor Salary of Martn Flores Rent* Annual equipment depreciation Equipment maintenance Direct departmental expenses 180,000 600,000 60,000 30,000 75,000 25,000 60,000 Distributed Fibertec overhead 50,000 1,080,000 * The rental costs of the main building were divided among the departments according to square meters. Fibertec Background Fibertec was a company that manufactured and processed a variety of natural products. It used highly advanced material processing technologies and had several departments engaged in the manufacture of numerous semi-finished products. The growing complexity of its products made the collaboration of engineering teams increasingly necessary. The Belgium-based company had a branch in Spain almost from the start. The Spanish office, which had six product departments, operated as a profit center that supplied its products globally. Its product strategy was fairly decentralized and it was able to make investment and disinvestment decisions on its own, requiring authorization from the head office in Belgium solely in the case of new product launches. Its clients had always been big industrial groups that used Fibertec products in their end products, such as in special storage containers and household and industrial textile products, among many others. The PTC Product Department From the very beginning, the PTC Product Department manufactured one of the company's leading products: PTC. At the time, it was considered to be a key product requested by many of its most important clients, and the company boasted about its particular skill in this area. However, this product did not generate especially high margins due to strong competitive pressure from alternative products. Jorge Ruiz, CEO of Fibertec, had received an offer from Engineering Tools regarding the possible outsourcing of supply and the adaptation of PTC to customer needs. In the five-year contract proposal, Engineering Tools offered to manufacture and adapt the 4,000 units of PTC for 975,000 per year. Under this offer, if demand were to increase, the total amount of the contract would increase proportionately. Ruiz asked David Barrios, head of accounting, to produce a report breaking down the costs of the PTC Product Department. The report found that the department's costs were higher than those of subcontracting the manufacture and adaptation of PTC (see Exhibit 1, PTC Product Department Costs, which shows the information provided by David Barrios). The Possibility of Outsourcing the PTC Product Department Ruiz called Martin Flores, head of the PTC Product Department, and passed along the calculations. Ruiz told him that it seemed clear that they should put an end to its internal manufacture. After examining the figures in Barrios' report, Flores, seemingly unconvinced, said: To make PTC we need LT4, a very expensive material that we still have in stock, which represents a third of the total cost of materials. If we were to buy it now, it would cost us 150 per ton, when we bought it for 120. Were we to sell it, we would only get back around 100 per ton. We anticipated a possible price increase and purchased five years' worth of LT4 for 300,000, and we have only used up the amount corresponding to the first year, which means we have four years' worth of LT4 left. It is also important to remember that we updated the machinery four years ago at a cost of 600,000. The investment was carried out with (conservative) calculations of a life span of eight years. In my estimation, if we sold it now we would make back 100,000 at Ruiz began to think that the decision, which initially seemed straightforward, wasn't as simple as he had thought. He called Barrios and Flores and put forward his doubts. Barrios thought his numbers were conclusive, Flores had doubts about the quality of the Engineering Tools product, and Ruiz wasn't sure about the real savings that would materialize. In short, there was no agreement regarding the figures presented by Barrios. Meanwhile, Flores was reluctant to dose his department and Ruiz assured him that his job was not in danger, given that Flores could occupy the position of another department head who was very close to retirement. At the meeting, Barrios defended the figures he had submitted. He said: I don't understand what the problem is with my calculations; I think they do a good job of representing the reality of the department. I haven't even taken into account the fact that the IT Department is currently located outside of the main building at a cost of 120,000 per year in rent. If we closed the department we could move IT into the main building, saving the rental costs. Flores, who had had time to examine the figures more closely, expressed doubts about the overhead costs, saying that the 50,000 (allocated to his department through an acconting Fibertec C-760 procedure) would not represent real savings for the company since it would not involve any reduction in costs. The most important thing to Flores, however, was his team. He was particularly worried about those who had been with the company the longest. Some employees were close to retirement age, but others, who had been with Fibertec for over 20 years, were of ages that would make it difficult to be hired by another company. What's more, they sometimes helped out with engineering tasks in other departments, though these departments paid the corresponding part of their wages. Flores thought that this aspect should not be considered in the decision. Finally, Flores said he didn't see where Barrios had included the severance pay that would have to be paid in the event of terminating the contracts of the department's employees. Barrios nodded and provided information on the delicate subject: "The total cost of the severance pay amounts to 660,000. Even though this is the amount calculated according to the law, we would probably have difficult negotiations with the unions about the subject" The Decision Ruiz was glad that he had included Flores in the deliberation, who, with a more realistic knowledge of the situation, had provided a very specific and pragmatic vision. He now had to decide, with the available options and estimates, what the best decision for Fibertec was. Exhibit 1 PTC Product Department Costs PTC materials Labor Salary of Martn Flores Rent* Annual equipment depreciation Equipment maintenance Direct departmental expenses 180,000 600,000 60,000 30,000 75,000 25,000 60,000 Distributed Fibertec overhead 50,000 1,080,000 * The rental costs of the main building were divided among the departments according to square meters

In the Fibertec case, you are analyzing 2 possible decisions- they are the traditional make or buy decisions that face firms.

Analyze the differential case flows of the 2 options

What are the comparative impacts on people, clients/customers?

Based on all these things, what is your recommended approach?

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started