Answered step by step

Verified Expert Solution

Question

1 Approved Answer

In the manufacture of semiconducting thin films, a thin film of solid arsenic is laid down onto the surface of a silicon wafer by the

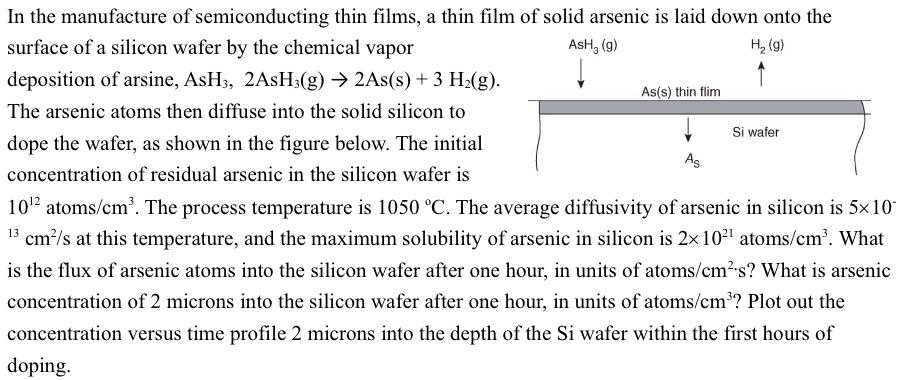

In the manufacture of semiconducting thin films, a thin film of solid arsenic is laid down onto the surface of a silicon wafer by the chemical vapor deposition of arsine, AsH3,2AsH3(g)2As(s)+3H2(g). The arsenic atoms then diffuse into the solid silicon to dope the wafer, as shown in the figure below. The initial concentration of residual arsenic in the silicon wafer is 1012 atoms /cm3. The process temperature is 1050C. The average diffusivity of arsenic in silicon is 510 13cm2/s at this temperature, and the maximum solubility of arsenic in silicon is 21021 atoms /cm3. What is the flux of arsenic atoms into the silicon wafer after one hour, in units of atoms /cm2s ? What is arsenic concentration of 2 microns into the silicon wafer after one hour, in units of atoms /cm3 ? Plot out the concentration versus time profile 2 microns into the depth of the Si wafer within the first hours of doping

In the manufacture of semiconducting thin films, a thin film of solid arsenic is laid down onto the surface of a silicon wafer by the chemical vapor deposition of arsine, AsH3,2AsH3(g)2As(s)+3H2(g). The arsenic atoms then diffuse into the solid silicon to dope the wafer, as shown in the figure below. The initial concentration of residual arsenic in the silicon wafer is 1012 atoms /cm3. The process temperature is 1050C. The average diffusivity of arsenic in silicon is 510 13cm2/s at this temperature, and the maximum solubility of arsenic in silicon is 21021 atoms /cm3. What is the flux of arsenic atoms into the silicon wafer after one hour, in units of atoms /cm2s ? What is arsenic concentration of 2 microns into the silicon wafer after one hour, in units of atoms /cm3 ? Plot out the concentration versus time profile 2 microns into the depth of the Si wafer within the first hours of doping Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started