Question

In the oxychlorination model, the distillate HCl from T-200 (stream 14) is recycled upstream to enter the oxychlorination reactor alongside the pure components. Similar to

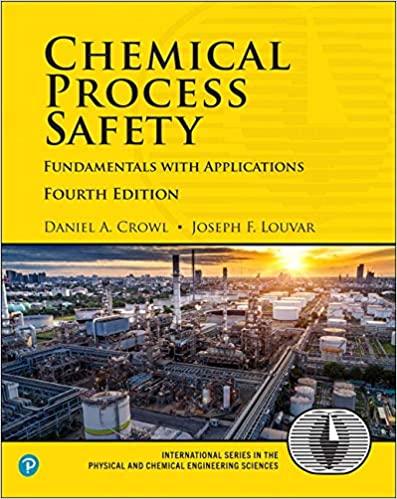

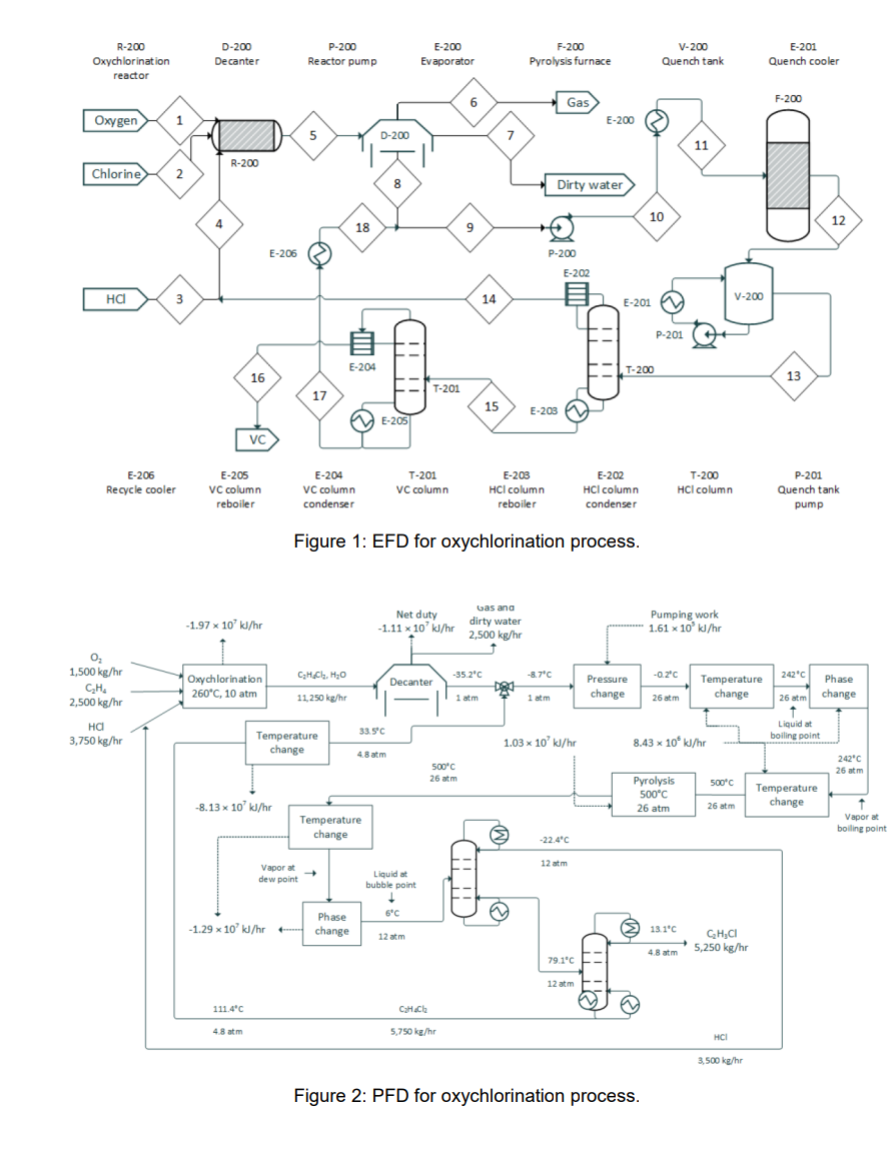

In the oxychlorination model, the distillate HCl from T-200 (stream 14) is recycled upstream to enter the oxychlorination reactor alongside the pure components. Similar to the direct chlorination process, the distillate from T-201 (stream 16) is 98% pure vinyl chloride at 13C and 4.8 atm. derive a differential balance on total mass and vinyl chloride if Stream 16 is to be stored in a well-mixed tank.

Stream 16: T= 13.1 c, pressure= 4.8 atm, vapor fraction =0 , mass flow[kg/hr]=5250 Mass flow [kmol/hr]=84, components molar flow[kmol/hr] : vinyl chloride 82.4, cl=0.05

Water=1 ,12 dichloroethane=0.1

R-200 Oxychlorination reactor D-200 Decanter P-200 Reactor pump E-200 Evaporator F-200 Pyrolysis furnace V-200 Quench tank E-201 Quench cooler 6 Gas F-200 Oxygen 1 E-200 5 D-200 7 11 R-200 Chlorine 2 8 Dirty water 10 4 12 18 9 9 E-206 P-200 - E-202 3 14 E-201 V-200 P-201 E-204 T-200 16 13 T-201 17 15 E-203 E-205 VC E-206 Recycle cooler E-205 VC column reboiler E-204 VC column condenser T-201 VC column E-203 HCl column reboiler E-202 HCl column condenser T-200 HCl column P-201 Quench tank pump Figure 1: EFD for oxychlorination process. -1.97 * 10% kJ/hr x ' / Net duty -1.11 X 10'kl/hr bas ana dirty water 2,500 kg/hr Pumping work 1.61 x 10k/hr -35.2C -870 -0.2C Oxychlorination 260C, 10 atm Decanter O 1,500 kg/hr CH 2,500 kg/hr 3,750 kg/hr , CHC 11.250 kg/h / Pressure change Temperature change 1m 1m 26 am 2420 Phase 26 at change 1 Liquidat boiling point Temperature 33.5C change 1.03 x 10 kJ/hr 8.43 x 10k/hr 48 am 500C 25 atm 242" 26 am Pyrolysis 500C 26 atm 500C 26 atm Temperature change -8.13* 10 kJ/hr x Temperature change Vapor at boiling point -22.4C 12 am Vapor at dew point Liquidat bubble point 6C Phase change -1.29 x 10'/hr kJ/ 13.1C 12 am CH, 79.10 48 tm 5,250 kg/hr am 12 am 111.4C CH.CH 48 am 5.750 kg/hr HCI 3.500 kg/hr Figure 2: PFD for oxychlorination process

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started