Question: In this project, you will work on a production scheduling problem of a pharmacy company that produces batches of custom drugs to order. The manufacturing

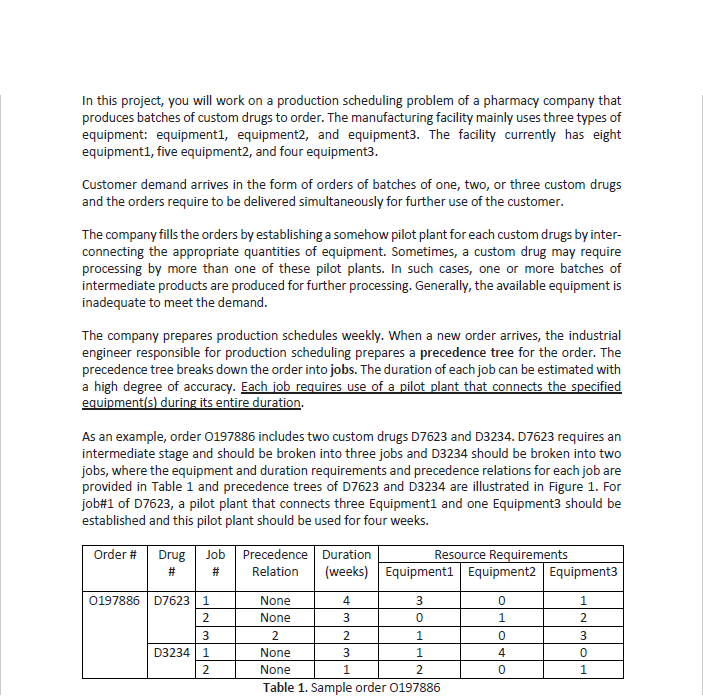

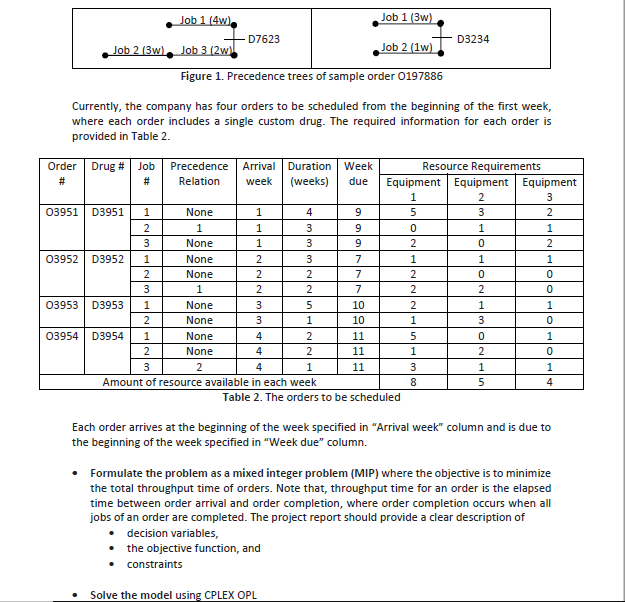

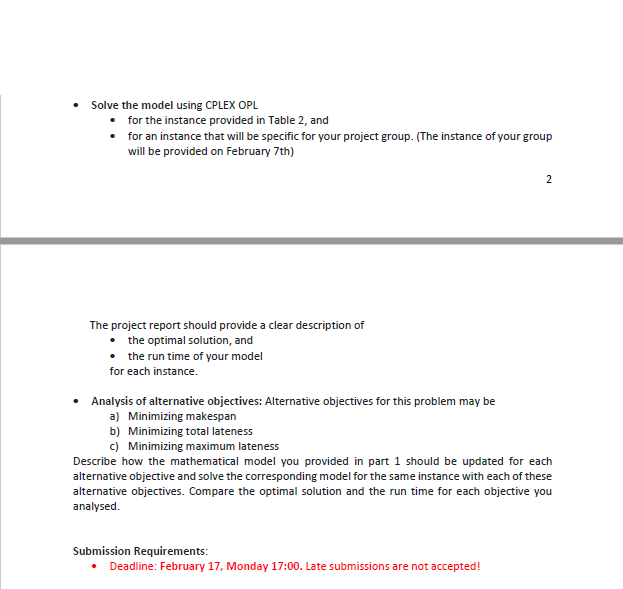

In this project, you will work on a production scheduling problem of a pharmacy company that produces batches of custom drugs to order. The manufacturing facility mainly uses three types of equipment: equipmenti, equipment2, and equipments. The facility currently has eight equipmenti, five equipment, and four equipment3. Customer demand arrives in the form of orders of batches of one, two, or three custom drugs and the orders require to be delivered simultaneously for further use of the customer. The company fills the orders by establishing a somehow pilot plant for each custom drugs by inter- connecting the appropriate quantities of equipment. Sometimes, a custom drug may require processing by more than one of these pilot plants. In such cases, one or more batches of intermediate products are produced for further processing. Generally, the available equipment is inadequate to meet the demand. The company prepares production schedules weekly. When a new order arrives, the industrial engineer responsible for production scheduling prepares a precedence tree for the order. The precedence tree breaks down the order into jobs. The duration of each job can be estimated with a high degree of accuracy. Each job requires use of a pilot plant that connects the specified equipment(s) during its entire duration. As an example, order 0197886 includes two custom drugs D7623 and D3234. D7623 requires an intermediate stage and should be broken into three jobs and D3234 should be broken into two jobs, where the equipment and duration requirements and precedence relations for each job are provided in Table 1 and precedence trees of D7623 and D3234 are illustrated in Figure 1. For job#1 of 07623, a pilot plant that connects three Equipment and one Equipment should be established and this pilot plant should be used for four weeks. Order # Drug Job Precedence Duration Resource Requirements Relation (weeks) Equipment Equipment Equipment3 0197886 076231 3 1 WN None None 0 2 1 None None 1 Table 1. Sample order 0197886 | D32341 2 i Job 1 (3w) Job 1/4w), +07623 Job 2 (3w), Job 3 (2w. +D3234 Job 2 (1w) Figure 1. Precedence trees of sample order 0197886 Currently, the company has four orders to be scheduled from the beginning of the first week, where each order includes a single custom drug. The required information for each order is provided in Table 2. Order Drug # Job Precedence Arrival | Duration Week Relation week (weeks) due Resource Requirements Equipment Equipment Equipment 03951 D3951 1 None 1 9 9 5 0 3 2 03952 D3952 1 None None None 3 None 03953 D3953 1 None 10 03954 D39541 None 12 None 4 1 2 11 1 11 Amount of resource available in each week Table 2. The orders to be scheduled 3 8 Each order arrives at the beginning of the week specified in "Arrival week" column and is due to the beginning of the week specified in "Week due" column. Formulate the problem as a mixed integer problem (MIP) where the objective is to minimize the total throughput time of orders. Note that, throughput time for an order is the elapsed time between order arrival and order completion, where order completion occurs when all jobs of an order are completed. The project report should provide a clear description of decision variables, the objective function, and constraints Solve the model using CPLEX OPL Solve the model using CPLEX OPL . for the instance provided in Table 2, and for an instance that will be specific for your project group. (The instance of your group will be provided on February 7th) The project report should provide a clear description of the optimal solution, and the run time of your model for each instance. Analysis of alternative objectives: Alternative objectives for this problem may be a) Minimizing makespan b) Minimizing total lateness c) Minimizing maximum lateness Describe how the mathematical model you provided in part 1 should be updated for each alternative objective and solve the corresponding model for the same instance with each of these alternative objectives. Compare the optimal solution and the run time for each objective you analysed. Submission Requirements: Deadline: February 17, Monday 17:00. Late submissions are not accepted! In this project, you will work on a production scheduling problem of a pharmacy company that produces batches of custom drugs to order. The manufacturing facility mainly uses three types of equipment: equipmenti, equipment2, and equipments. The facility currently has eight equipmenti, five equipment, and four equipment3. Customer demand arrives in the form of orders of batches of one, two, or three custom drugs and the orders require to be delivered simultaneously for further use of the customer. The company fills the orders by establishing a somehow pilot plant for each custom drugs by inter- connecting the appropriate quantities of equipment. Sometimes, a custom drug may require processing by more than one of these pilot plants. In such cases, one or more batches of intermediate products are produced for further processing. Generally, the available equipment is inadequate to meet the demand. The company prepares production schedules weekly. When a new order arrives, the industrial engineer responsible for production scheduling prepares a precedence tree for the order. The precedence tree breaks down the order into jobs. The duration of each job can be estimated with a high degree of accuracy. Each job requires use of a pilot plant that connects the specified equipment(s) during its entire duration. As an example, order 0197886 includes two custom drugs D7623 and D3234. D7623 requires an intermediate stage and should be broken into three jobs and D3234 should be broken into two jobs, where the equipment and duration requirements and precedence relations for each job are provided in Table 1 and precedence trees of D7623 and D3234 are illustrated in Figure 1. For job#1 of 07623, a pilot plant that connects three Equipment and one Equipment should be established and this pilot plant should be used for four weeks. Order # Drug Job Precedence Duration Resource Requirements Relation (weeks) Equipment Equipment Equipment3 0197886 076231 3 1 WN None None 0 2 1 None None 1 Table 1. Sample order 0197886 | D32341 2 i Job 1 (3w) Job 1/4w), +07623 Job 2 (3w), Job 3 (2w. +D3234 Job 2 (1w) Figure 1. Precedence trees of sample order 0197886 Currently, the company has four orders to be scheduled from the beginning of the first week, where each order includes a single custom drug. The required information for each order is provided in Table 2. Order Drug # Job Precedence Arrival | Duration Week Relation week (weeks) due Resource Requirements Equipment Equipment Equipment 03951 D3951 1 None 1 9 9 5 0 3 2 03952 D3952 1 None None None 3 None 03953 D3953 1 None 10 03954 D39541 None 12 None 4 1 2 11 1 11 Amount of resource available in each week Table 2. The orders to be scheduled 3 8 Each order arrives at the beginning of the week specified in "Arrival week" column and is due to the beginning of the week specified in "Week due" column. Formulate the problem as a mixed integer problem (MIP) where the objective is to minimize the total throughput time of orders. Note that, throughput time for an order is the elapsed time between order arrival and order completion, where order completion occurs when all jobs of an order are completed. The project report should provide a clear description of decision variables, the objective function, and constraints Solve the model using CPLEX OPL Solve the model using CPLEX OPL . for the instance provided in Table 2, and for an instance that will be specific for your project group. (The instance of your group will be provided on February 7th) The project report should provide a clear description of the optimal solution, and the run time of your model for each instance. Analysis of alternative objectives: Alternative objectives for this problem may be a) Minimizing makespan b) Minimizing total lateness c) Minimizing maximum lateness Describe how the mathematical model you provided in part 1 should be updated for each alternative objective and solve the corresponding model for the same instance with each of these alternative objectives. Compare the optimal solution and the run time for each objective you analysed. Submission Requirements: Deadline: February 17, Monday 17:00. Late submissions are not accepted

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts