Question

Industrial and Systems Engineering Program Computer Simulation Systems IENG 350 Spring 2018 Term Project Background A small electronics manufacturer produces electronic parts used by a

Industrial and Systems Engineering Program

Computer Simulation Systems

IENG 350 Spring 2018

Term Project

Background

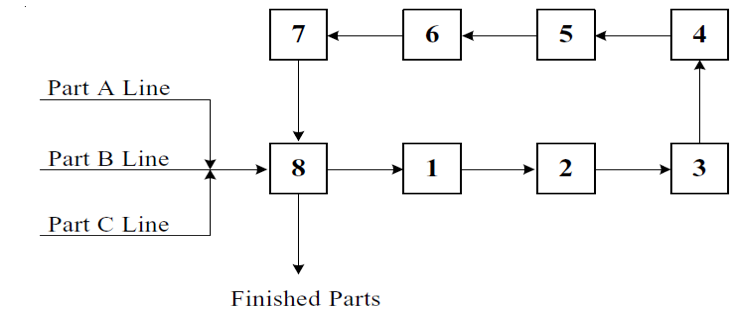

A small electronics manufacturer produces electronic parts used by a variety of other manufacturers. Recently, the company noticed problems in a department that produces three different parts. The demand mix for these three products has changed slowly over time. The department is almost fully automated and consists of four lines. Each of the first three lines produces a single product and they have all been modified over time to meet the current demand mix. When the almost-finished parts (Parts A, B, and C) exit these three lines, they all enter the fourth line where the final operations are performed for all product types. The new product mix has caused the fourth line to become a bottleneck. The company employed several consultants to collect data and recommend modifications to this line. Although the company received sufficient information to proceed with modifications, the actual performance after the modifications are implemented is in question. Two different approaches were suggested. At this time, its not clear which approach would provide the best results. Its also possible that both suggested modifications may be required in order to achieve the desired performance. In light of this uncertainty, the company initiated a request for recommendations. You are asked to evaluate the current design and propose the configuration(s) that will result in approximately minimizing operating cost while still achieving the desired performance levels. A description of the current system is described together with the two different modifications that have been proposed. Your analysis should concentrate on the fourth line, and a schematic of it is shown in Figure 1.

Figure 1: Production Line for the Small Electronics Manufacturer

Description of Operations

Parts A, B, and C enter the fourth line on the left. Since the lines that produce these parts are fully automated, their arrival rates are very predictable. The normal arrivals for the three parts are: Part A, every 2.8 minutes; Part B, every 1.4 minutes; and Part C, every 2.0 minutes. There are occasional jams on these lines, which can cause slight delays in part arrivals. The collected data show that delays occur 2%, 1.75%, and 0.5% of the time on Lines A, B, and C, respectively. The data for these delays have been analyzed and triangular distributions have been fitted to the data. The parameters for these distributions are (5, 15, 60), (5, 20, 55), and (5, 20, 65) for Lines A, B, and C, respectively. Note that the time units for these parameters are in seconds.

The arriving parts are merged (in the order in which they arrive) onto a single input conveyor, which feeds the fourth and final system. The input conveyor from the merge point to where the parts enter the fourth system has room for 40 parts. If this input conveyor becomes full and a new part attempts to merge onto the conveyor, then the line producing that part temporarily shuts down until space becomes available. Currently, there are numerous shutdowns during each day. For analysis purposes, you can assume that if a part arrives and the input conveyor is full, that part is considered to be lost production. The cost for a lost part is $0.89, $0.63, and $0.72 for Parts A, B, and C, respectively. The fourth system consists of eight work cells connected by a power-and-free conveyor. The distance between each work cell is 18 feet. When a new part enters the system from the input conveyor at Work Cell 8, it must wait for a special pallet that will hold the part as it travels through the system. Presently, there are 40 pallets in the system, each requiring 2 feet of space. Thus, there is room for eight pallets between each pair of successive work cells (16 feet of buffer space and 2 feet for the work cell). The travel time between work cells (18 feet) is 15 seconds. When both a pallet and a new part are available at Work Cell 8, the finished part is first removed from the pallet, and then the new part is loaded. This unload/load process is fully automated and takes 25 seconds. A jam occurs approximately 1% of the time, requiring additional time. Once the unload/load process is complete, the pallet moves to the buffer area in front of Work Cell 1. If there is no room in the buffer area, the pallet remains at the unload/load work cell until room becomes available. In effect, the waiting loaded pallet blocks the unload/load work cell. The new part moves through the system where an operation is performed at each of the remaining seven work cells. Work Cells 1, 3, 4, 5, and 6 are automated operations. Work Cells 2 and 7 are manual operations. There will be a fixed setup time in all automated operations, which takes 20 seconds.

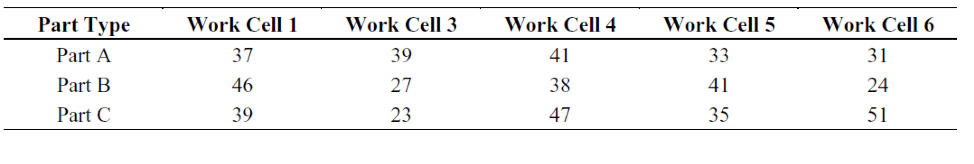

The operation or process time at the automated work cells is part dependent. These operation times (in seconds) are given in Table 2.

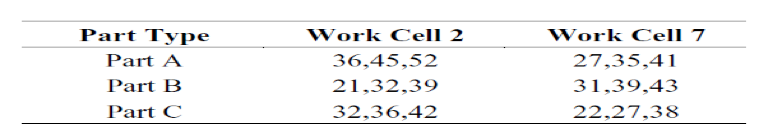

For example, a Part B at Work Cell 4 requires a 38-second operation time. The operation or process times at the two manual work cells follow triangular distributions with the parameters given, in seconds (see Table 3). No setup is required at the manual work cells.

Based on observations it can be assumed that the factory is currently working two shifts, a 16-hour production day, five days a week.

Proposed Modifications

The first proposed modification requires that the company add five more pallets to the existing fourth system. Since the current control logic for that system was developed specifically for 40 pallets, that logic must be modified. The fixed cost for this modification is $17,000. This cost is incurred even if only one pallet is added. In addition, there is an incremental cost of $3,000 for each pallet added.

e second proposed modification requires that the company insert additional space for incoming parts by adding three new buffer conveyors. The amount of additional storage is limited, based on available space. The current available space would allow three buffer conveyors to be added at the incoming merge point, one conveyor for each part type. Each of these conveyors would have space for an additional five parts. The concept is that each of the first three lines would insert their parts into their own buffer conveyor (limited to five parts on each conveyor). Logic would then be developed that would allow these parts to be released in batches to the existing buffer conveyor (limited to 40 parts). In this case, the setup time at each of the automated operations will reduced by 5%. The company has already priced this option with a conveyor manufacturer. The cost to implement this modification is $56,000. This cost includes the equipment cost, installation cost, and the development of whatever release logic is required.

Requirements

1-Model the production line in Arena simulation software

2-Evaluate the current design of the production system

3-Use simulation to analyze the various configurations suggested by the proposed modifications

4-Provide a suitable design/redesign of the production line in order to meet the performance requirements of the manufacturer

7 6 Part A Line Part B Line-x-->| 3 8 2 Part C Line Finished Parts 7 6 Part A Line Part B Line-x-->| 3 8 2 Part C Line Finished PartsStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started