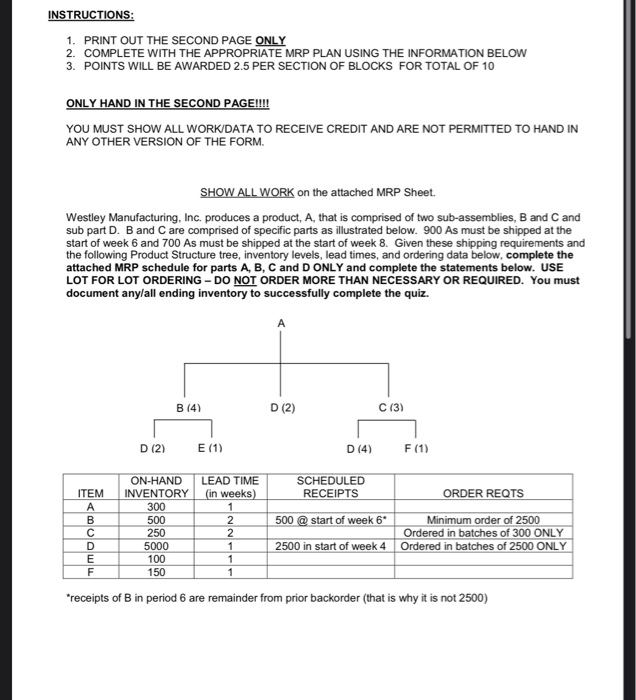

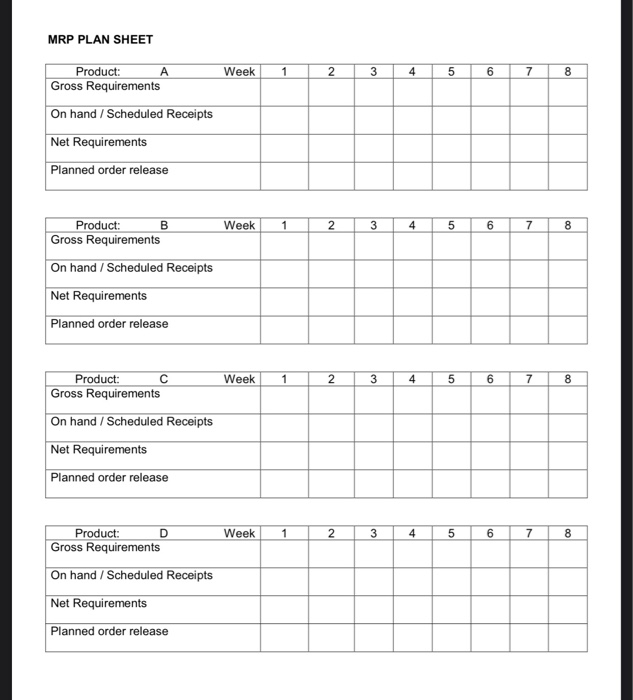

INSTRUCTIONS: 1. PRINT OUT THE SECOND PAGE ONLY THE APPROPRIATE MRP PLAN USING THE INFORMATION BELOW 3. POINTS WILL BE AWARDED 2.5 PER SECTION OF BLOCKS FOR TOTAL OF 10 ONLY HAND IN THE SECOND PAGE!!!! YOU MUST SHOW ALL WORK/DATA TO RECEIVE CREDIT AND ARE NOT PERMITTED TO HAND IN ANY OTHER VERSION OF THE FORM. SHOW ALL WORK on the attached MRP Sheet. Westley Manufacturing, Inc. produces a product, A, that is comprised of two sub-assemblies, B and C and sub part D. Band C are comprised of specific parts as illustrated below. 900 As must be shipped at the start of week 6 and 700 As must be shipped at the start of week 8. Given these shipping requirements and the following Product Structure tree, inventory levels, lead times, and ordering data below, complete the attached MRP schedule for parts A, B, C and D ONLY and complete the statements below. USE LOT FOR LOT ORDERING - DO NOT ORDER MORE THAN NECESSARY OR REQUIRED. You must document any/all ending inventory to successfully complete the quiz. B (4) D (2) C (3) D (2) E (1) D (4) F (1) ITEM LEAD TIME (in weeks) SCHEDULED RECEIPTS ORDER REQTS B ON-HAND INVENTORY 300 500 250 5000 100 150 2 2 500 @ start of week 6 Minimum order of 2500 Ordered in batches of 300 ONLY Ordered in batches of 2500 ONLY D 1 2 500 in start of week 4 "receipts of B in period 6 are remainder from prior backorder (that is why it is not 2500) MRP PLAN SHEET Week 1 2 3 4 5 6 7 8 Product: A Gross Requirements On hand / Scheduled Receipts Net Requirements Planned order release Week 1 2 3 4 5 Product: B Gross Requirements On hand / Scheduled Receipts Net Requirements Planned order release Product: C Gross Requirements W eek 1 2 3 4 5 6 7 8 On hand / Scheduled Receipts Net Requirements Planned order release Product: D Gross Requirements Week 1 On hand / Scheduled Receipts Net Requirements Planned order release INSTRUCTIONS: 1. PRINT OUT THE SECOND PAGE ONLY THE APPROPRIATE MRP PLAN USING THE INFORMATION BELOW 3. POINTS WILL BE AWARDED 2.5 PER SECTION OF BLOCKS FOR TOTAL OF 10 ONLY HAND IN THE SECOND PAGE!!!! YOU MUST SHOW ALL WORK/DATA TO RECEIVE CREDIT AND ARE NOT PERMITTED TO HAND IN ANY OTHER VERSION OF THE FORM. SHOW ALL WORK on the attached MRP Sheet. Westley Manufacturing, Inc. produces a product, A, that is comprised of two sub-assemblies, B and C and sub part D. Band C are comprised of specific parts as illustrated below. 900 As must be shipped at the start of week 6 and 700 As must be shipped at the start of week 8. Given these shipping requirements and the following Product Structure tree, inventory levels, lead times, and ordering data below, complete the attached MRP schedule for parts A, B, C and D ONLY and complete the statements below. USE LOT FOR LOT ORDERING - DO NOT ORDER MORE THAN NECESSARY OR REQUIRED. You must document any/all ending inventory to successfully complete the quiz. B (4) D (2) C (3) D (2) E (1) D (4) F (1) ITEM LEAD TIME (in weeks) SCHEDULED RECEIPTS ORDER REQTS B ON-HAND INVENTORY 300 500 250 5000 100 150 2 2 500 @ start of week 6 Minimum order of 2500 Ordered in batches of 300 ONLY Ordered in batches of 2500 ONLY D 1 2 500 in start of week 4 "receipts of B in period 6 are remainder from prior backorder (that is why it is not 2500) MRP PLAN SHEET Week 1 2 3 4 5 6 7 8 Product: A Gross Requirements On hand / Scheduled Receipts Net Requirements Planned order release Week 1 2 3 4 5 Product: B Gross Requirements On hand / Scheduled Receipts Net Requirements Planned order release Product: C Gross Requirements W eek 1 2 3 4 5 6 7 8 On hand / Scheduled Receipts Net Requirements Planned order release Product: D Gross Requirements Week 1 On hand / Scheduled Receipts Net Requirements Planned order release