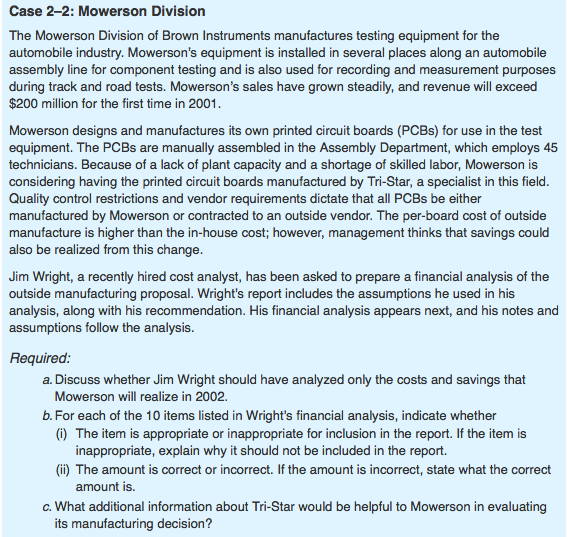

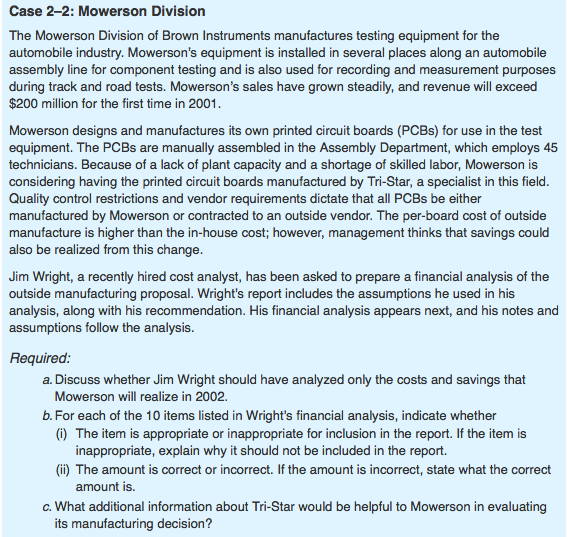

introduction for case study 100 words

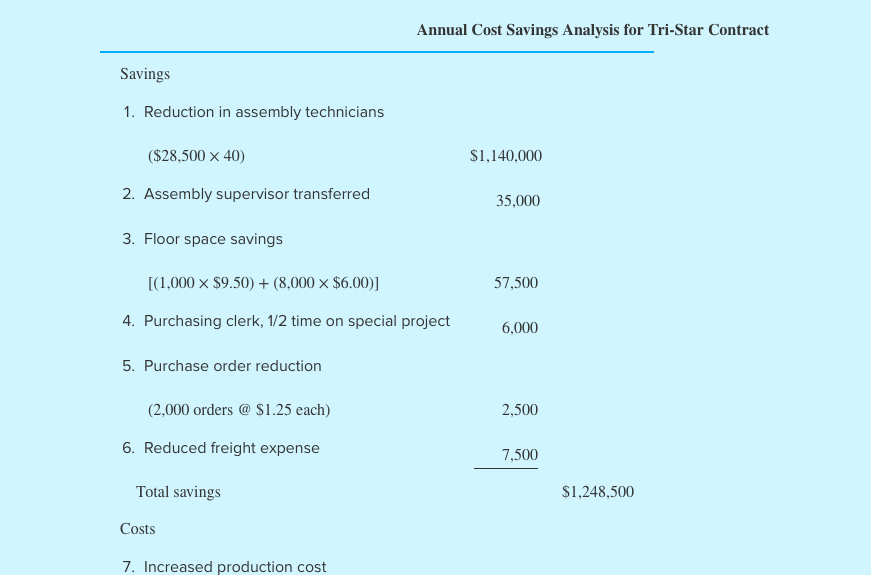

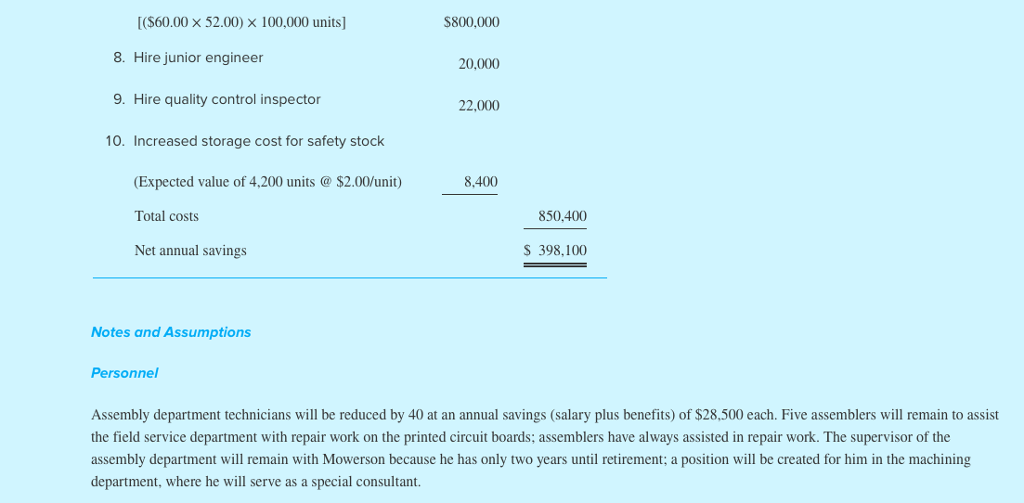

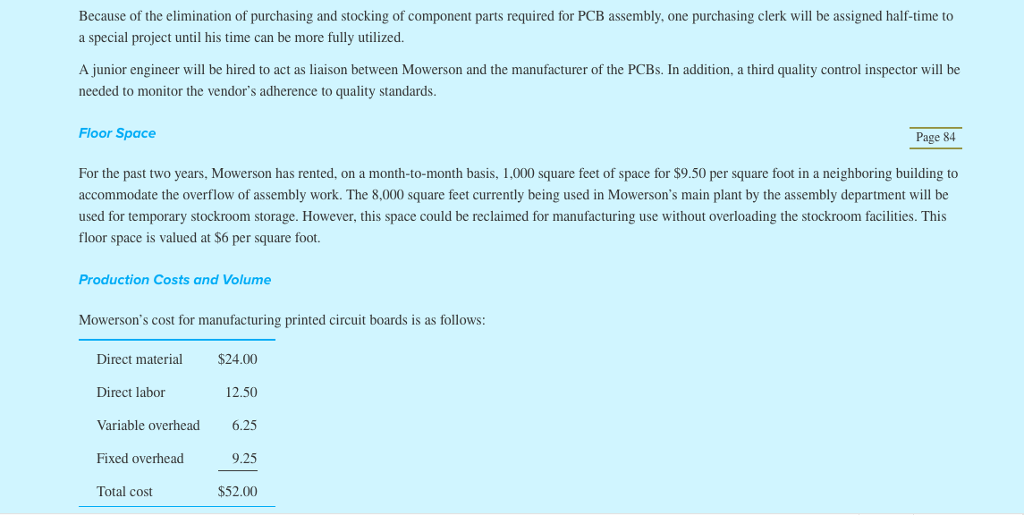

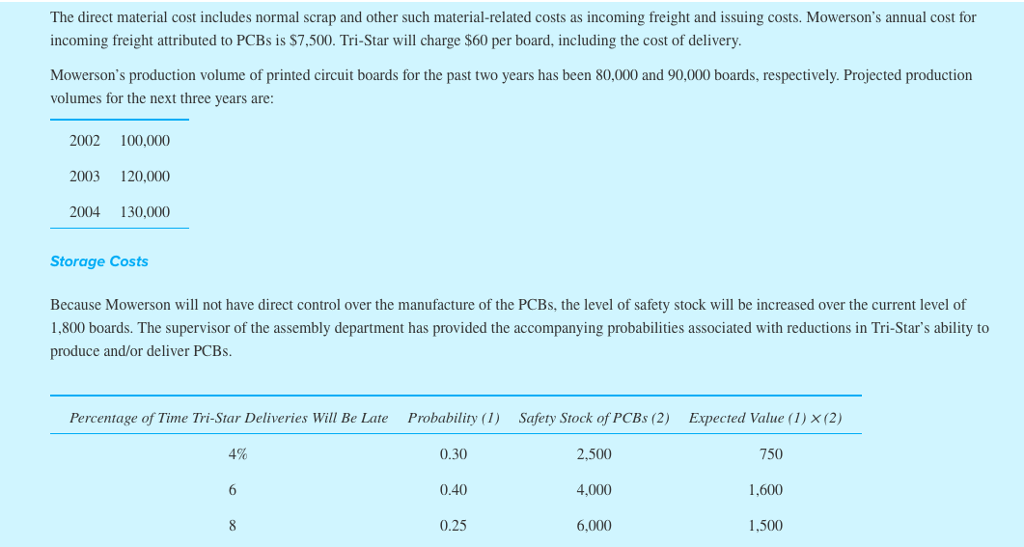

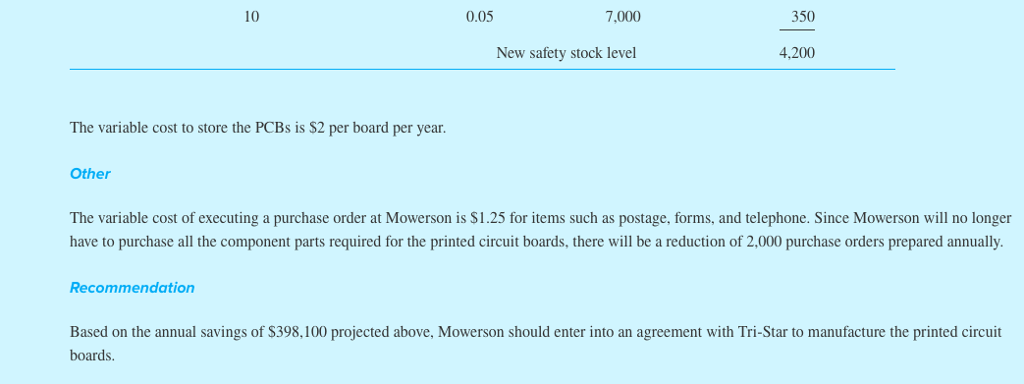

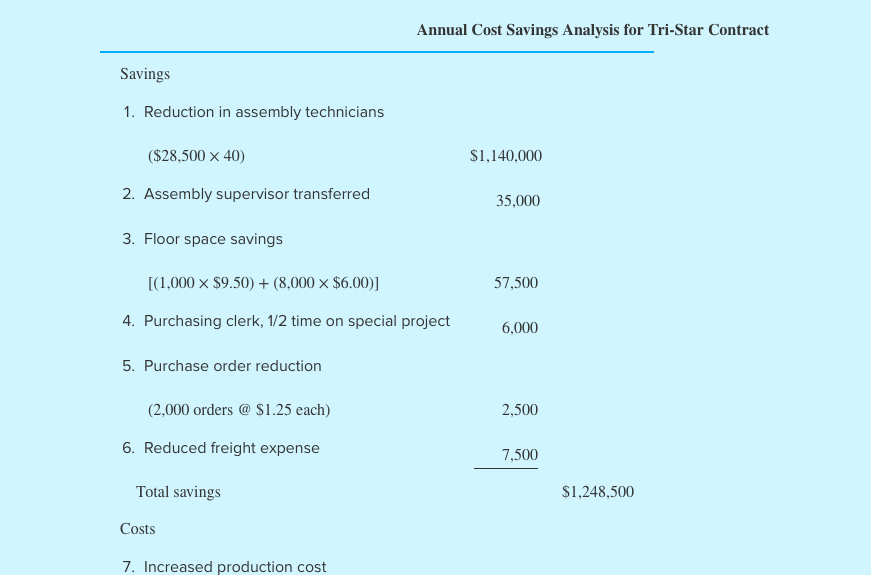

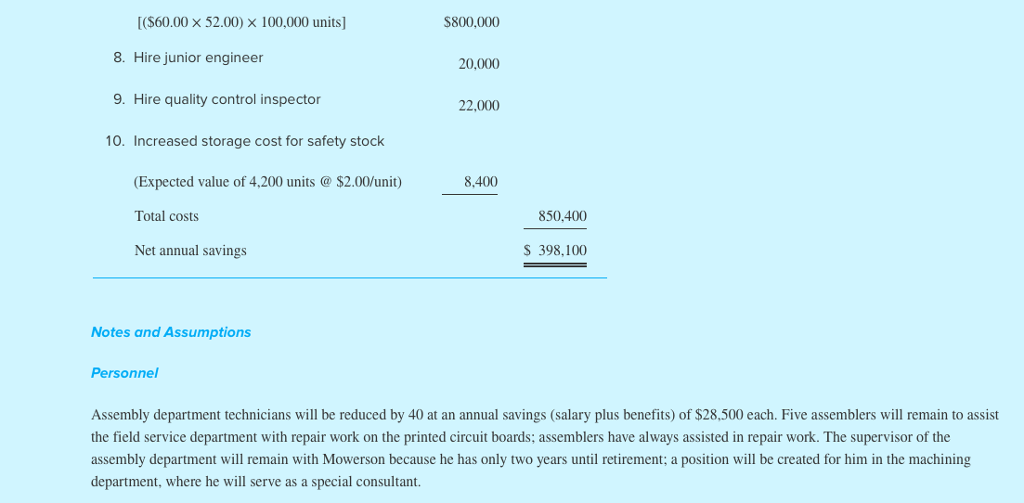

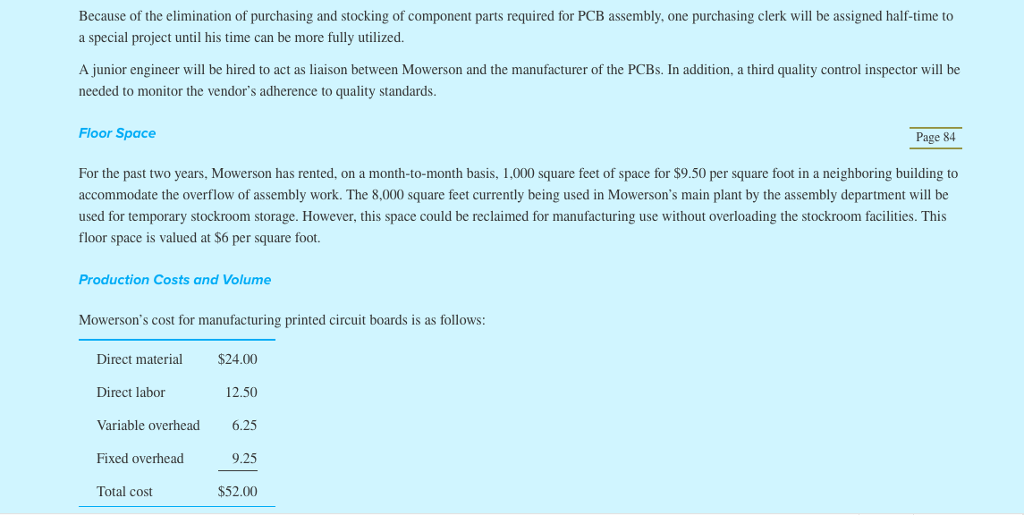

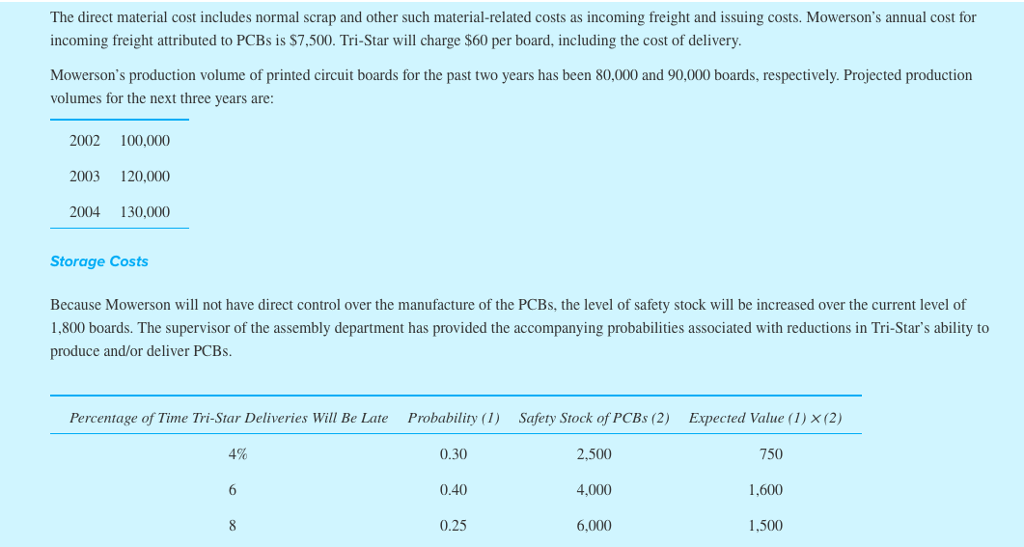

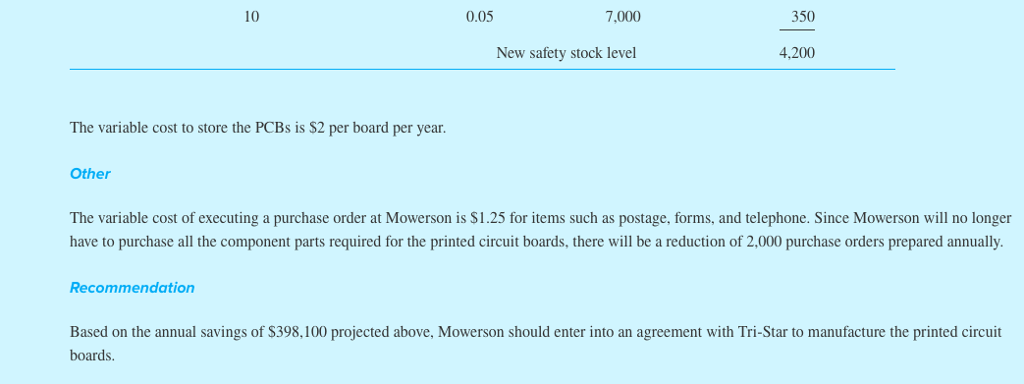

Annual Cost Savings Analysis for Tri-Star Contract Savings 1. Reduction in assembly technicians ($28,500 x 40) 2. Assembly supervisor transferred 3. Floor space savings $1,140,000 35,000 (1,000 x S9.50) (8,000 x $6.00)] 57,500 4. Purchasing clerk, 1/2 time on special project 6,000 5. Purchase order reduction (2.000 orders@ $1.25 each) 2,500 6. Reduced freight expense 7,500 Total savings Costs 7. Increased production cost $1,248,500 Because of the elimination of purchasing and stocking of component parts required for PCB assembly, one purchasing clerk will be assigned half-time to a special project until his time can be more fully utilized. A junior engineer will be hired to act as liaison between Mowerson and the manufacturer of the PCBs. In addition, a third quality control inspector will be needed to monitor the vendor's adherence to quality standards. Floor Space Page 84 For the past two years, Mowerson has rented, on a month-to-month basis, 1,000 square feet of space for $9.50 per square foot in a neighboring building to accommodate the overflow of assembly work. The 8,000 square feet currently being used in Mowerson's main plant by the assembly department will be used for temporary stockroom storage. However, this space could be reclaimed for manufacturing use without overloading the stockroom facilities. This floor space is valued at S6 per square foot. Production Costs and Volume Mowerson's cost for manufacturing printed circuit boards is as follows: Direct material Direct labor Variable overhead Fixed overhead Total cost $24.00 12.50 6.25 9.25 $52.00 The direct material cost includes normal scrap and other such material-related costs as incoming freight and issuing costs. Mowerson's annual cost for incoming freight attributed to PCBs is S7,500. Tri-Star will charge $60 per board, including the cost of delivery. Mowerson's production volume of printed circuit boards for the past two years has been 80,000 and 90,000 boards, respectively. Projected production volumes for the next three years are: 2002 100,000 2003 120,000 2004 130,000 Storage Costs Because Mowerson will not have direct control over the manufacture of the PCBs, the level of safety stock will be increased over the current level of 1,800 boards. The supervisor of the assembly department has provided the accompanying probabilities associated with reductions in Tri-Star's ability to produce and/or deliver PCBs Percentage of Time Tri-Star Deliveries Will Be Late Probability (1) Safety Stock of PCBs (2) Expected Value () x (2) 0.30 0.40 0.25 2,500 4,000 6,000 750 1,600 1,500 4%