Answered step by step

Verified Expert Solution

Question

1 Approved Answer

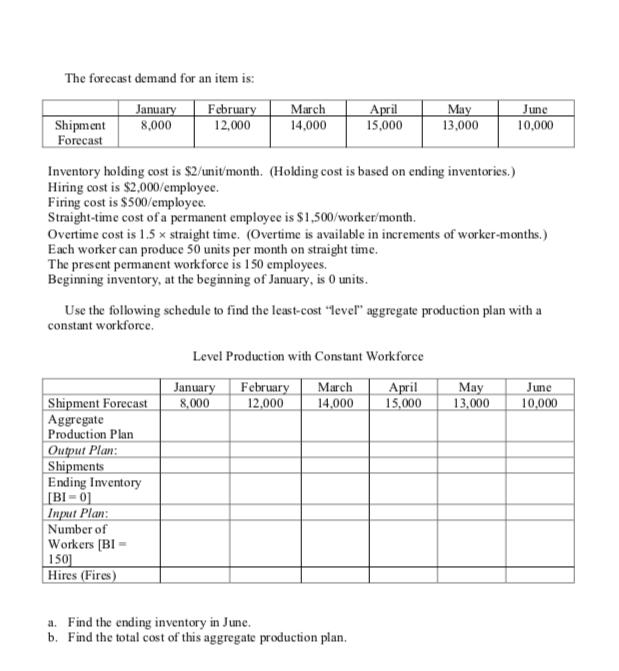

The forecast demand for an item is: January Shipment 8,000 Forecast February 12,000 Shipment Forecast Aggregate Production Plan Output Plan: Shipments Ending Inventory [BI=0]

The forecast demand for an item is: January Shipment 8,000 Forecast February 12,000 Shipment Forecast Aggregate Production Plan Output Plan: Shipments Ending Inventory [BI=0] March 14,000 Inventory holding cost is $2/unit/month. (Holding cost is based on ending inventories.) Hiring cost is $2,000/employee. Firing cost is $500/employee. Straight-time cost of a permanent employee is $1,500/worker/month. Input Plan: Number of Workers [BI- 150] Hires (Fires) April 15,000 Overtime cost is 1.5 x straight time. (Overtime is available in increments of worker-months.) Each worker can produce 50 units per month on straight time. The present permanent workforce is 150 employees. Beginning inventory, at the beginning of January, is 0 units. May 13,000 Use the following schedule to find the least-cost "level" aggregate production plan with a constant workforce. a. Find the ending inventory in June. b. Find the total cost of this aggregate production plan. June 10,000 Level Production with Constant Workforce January February March April May 12,000 14,000 15,000 13,000 8,000 June 10,000

Step by Step Solution

★★★★★

3.53 Rating (153 Votes )

There are 3 Steps involved in it

Step: 1

Current capacity 150x507500 Required capacity 1200050240 Month Jan Feb MAR Apr May June Forecast 800...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started