Answered step by step

Verified Expert Solution

Question

1 Approved Answer

It's a project so can you please answer in brief and project way Here is the questions 1. Background The Tamiami Bridge is part of

It's a project so can you please answer in brief and project way

Here is the questions

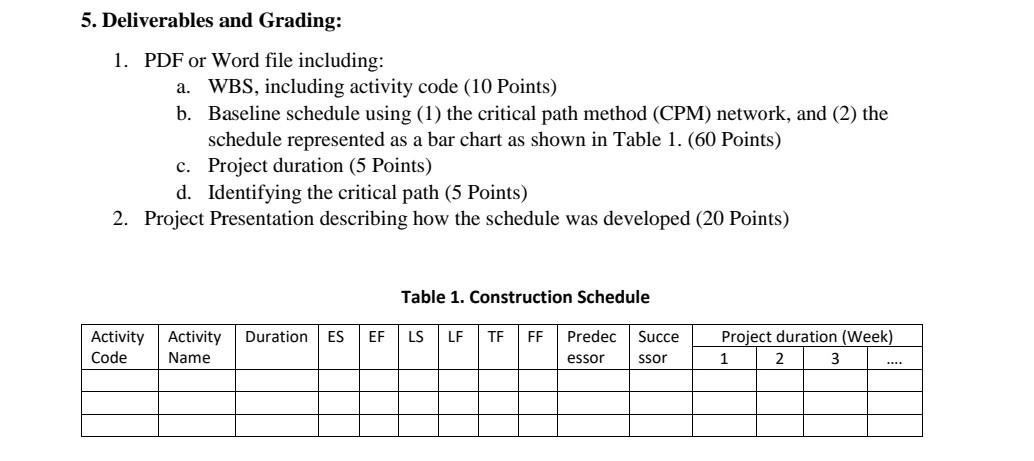

1. Background The Tamiami Bridge is part of a comprehensive road improvement project recently awarded to KTC Construction, a national contractor with offices throughout North America. The project includes maintenance of traffic, utility relocation, grading and highway work as well as the 5,280' long Tamiami Bridge which spans a section of swampy ground near the western end of the project. The bridge is about 70% of the total contract value and its successful completion is critical to the success of the project as a whole. The bridge is a simple, repetitive, high production concrete structure comprising 66 identical 80' spans resting on 67 pile supported bents. The plan and elevation of the bridge are given in Appendix I 1. Piling details are given in Appendix I 2. Details of a typical bent cap and a cross section of the superstructure are given in Appendix I 3. You work in the Florida office of KTC Construction and have been given responsibility for the piling operations required to construct the 67 pile supported bents. As such you are a member of the project leadership team and report directly to Pam Moore the, KTC Construction project manager. Your responsibilities include only the direct piling operations. Other members of the leadership team are responsible for the cast in situ concrete work, the precast beams, the deck and the associated road works. 2. Piling operations The piling operations themselves break down into four distinct phases, mobilization, testpiling and production piling. Mobilization includes the following three activities: 1. Submit and obtain approval of piling procedures. 2. Submit and obtain approval of pile specifications. 3. Procure pre-approved test piles. Test piling includes only one activity: 1. Install test piles at locations shown on sheets S314 to 320 including all predrilling, driving, grouting and testing. Procurement this follows test piling and includes: 1. Submit geotechnical consultant's report following installation of test piles. 2. Submit and obtain approval of order list for production piles. 3. Procure and schedule delivery of production piles. Production piling comprises the following three activities: 1. Pre-drill 18' deep shafts to assist pile driving. 2. Drive production piles to the required limits. 3. Grout void between pre-drilled holes and driven piles. 3. Strategic approach to sequencing the work The principal strategic decisions regarding the sequencing and scheduling of the work were taken during bid preparation. The four affecting the piling operations most may be summarized as follows: 1) Construction will commence with bent \#1 at the western end of the project and continue from there continuously towards the eastern end of the project. 2) Production piling will be speeded up by installing all test piles using a separate crew that will work continuously from west to east to complete this activity before being reassigned to assist with beam placement. 3) The geotechnical consultant's report and the order list for production piles will be split into two parts; one covering the piles needed for Units 1 to 8 and the other covering the piles needed for Units 9 to 17 . The importance of this decision stems from the fact that the contract special provisions contains a clause stating: "The Contractor shall submit to the Contracting Officer for approval, an itemized list for piles prior to placing the order with the supplier. The list shall indicate the pile lengths required at each location as shown on the plans and the corresponding order length of each pile. Pile testing shall be completed prior to submission of an order list." This requirement places prerequisite constraints between (i) completing pile testing, (ii) submitting the geotechnical consultant's report and, (iii) submitting the order list for production piles. These constraints delay the start of production piling to an unacceptable extent and the Contracting Officer agreed to accept a two phase submittal for the geotechnical consultant's report and the order list with the first phase covering Units 1 to 8 and the second phase covering Units 9 to 17 . The agreement was reached during the preconstruction conference when the Contracting Officer was convinced that the benefits of schedule compression outweighed the disadvantages of the two phase submittal process. Subsequent negotiations with the pile supplier secured their commitment to the two phase submittal process. 4) Two crews will be used for the production piling operations. The main crew will be responsible for pile driving and progress from Unit 1 to Unit 17 without interruption. The second smaller crew will be responsible for pre-drilling and grouting. Pre-drilling will be done a maximum of one Unit in advance of the pile driving and the crew will fall back to grout the void between the pre-drilled hole and the pile no more than one unit after piling is complete for a particular Unit. 4. Crews and productions The strategic decisions made regarding the sequencing and scheduling of the work mandates the use of three crews to perform the work. Their work assignments, schedules and production rates may be summarized as follows: Alfonso: Alfonso's crew and equipment will be responsible for all operations - predrilling, driving and grouting - regarding the test piles. Their work will commence immediately after the pre-approved test piles have been procured and will continue at a rate of 2 test piles per week until all test piles are complete. The crew and equipment will be reassigned to assist with lifting and placing bridge beams once all test piles are complete. Pat: Pat's crew and equipment will be responsible for the production pile driving itself. They will start work as soon as the production piles are on site and the required pre-drilling is complete. They will start with Unit 1 and progress to Unit 17 at an uninterrupted production rate of 1 Unit every 2 weeks. This rate will require that the team work 10 shifts per week and the crew includes the resources necessary to support a night shift. This specialized high production piling crew will be reassigned to another project on completion of the work. Charlie: Charlie's crew and equipment will be responsible for the pre-drilling and grouting operations that will each take no more than 1 week to complete. Their schedule is determined by Pat's crew in that they are required to do the pre-drilling for a given Unit no more than 1 week in advance of the start of pile driving for that Unit and must complete grouting within 1 week of completion of pile driving for that Unit. This versatile utility crew will be reassigned to another phase of the project on completion of these activities. 5. Deliverables and Grading: 1. PDF or Word file including: a. WBS, including activity code (10 Points) b. Baseline schedule using (1) the critical path method (CPM) network, and (2) the schedule represented as a bar chart as shown in Table 1. (60 Points) c. Project duration (5 Points) d. Identifying the critical path (5 Points) 2. Project Presentation describing how the schedule was developed (20 Points) Table 1. Construction Schedule 1. Background The Tamiami Bridge is part of a comprehensive road improvement project recently awarded to KTC Construction, a national contractor with offices throughout North America. The project includes maintenance of traffic, utility relocation, grading and highway work as well as the 5,280' long Tamiami Bridge which spans a section of swampy ground near the western end of the project. The bridge is about 70% of the total contract value and its successful completion is critical to the success of the project as a whole. The bridge is a simple, repetitive, high production concrete structure comprising 66 identical 80' spans resting on 67 pile supported bents. The plan and elevation of the bridge are given in Appendix I 1. Piling details are given in Appendix I 2. Details of a typical bent cap and a cross section of the superstructure are given in Appendix I 3. You work in the Florida office of KTC Construction and have been given responsibility for the piling operations required to construct the 67 pile supported bents. As such you are a member of the project leadership team and report directly to Pam Moore the, KTC Construction project manager. Your responsibilities include only the direct piling operations. Other members of the leadership team are responsible for the cast in situ concrete work, the precast beams, the deck and the associated road works. 2. Piling operations The piling operations themselves break down into four distinct phases, mobilization, testpiling and production piling. Mobilization includes the following three activities: 1. Submit and obtain approval of piling procedures. 2. Submit and obtain approval of pile specifications. 3. Procure pre-approved test piles. Test piling includes only one activity: 1. Install test piles at locations shown on sheets S314 to 320 including all predrilling, driving, grouting and testing. Procurement this follows test piling and includes: 1. Submit geotechnical consultant's report following installation of test piles. 2. Submit and obtain approval of order list for production piles. 3. Procure and schedule delivery of production piles. Production piling comprises the following three activities: 1. Pre-drill 18' deep shafts to assist pile driving. 2. Drive production piles to the required limits. 3. Grout void between pre-drilled holes and driven piles. 3. Strategic approach to sequencing the work The principal strategic decisions regarding the sequencing and scheduling of the work were taken during bid preparation. The four affecting the piling operations most may be summarized as follows: 1) Construction will commence with bent \#1 at the western end of the project and continue from there continuously towards the eastern end of the project. 2) Production piling will be speeded up by installing all test piles using a separate crew that will work continuously from west to east to complete this activity before being reassigned to assist with beam placement. 3) The geotechnical consultant's report and the order list for production piles will be split into two parts; one covering the piles needed for Units 1 to 8 and the other covering the piles needed for Units 9 to 17 . The importance of this decision stems from the fact that the contract special provisions contains a clause stating: "The Contractor shall submit to the Contracting Officer for approval, an itemized list for piles prior to placing the order with the supplier. The list shall indicate the pile lengths required at each location as shown on the plans and the corresponding order length of each pile. Pile testing shall be completed prior to submission of an order list." This requirement places prerequisite constraints between (i) completing pile testing, (ii) submitting the geotechnical consultant's report and, (iii) submitting the order list for production piles. These constraints delay the start of production piling to an unacceptable extent and the Contracting Officer agreed to accept a two phase submittal for the geotechnical consultant's report and the order list with the first phase covering Units 1 to 8 and the second phase covering Units 9 to 17 . The agreement was reached during the preconstruction conference when the Contracting Officer was convinced that the benefits of schedule compression outweighed the disadvantages of the two phase submittal process. Subsequent negotiations with the pile supplier secured their commitment to the two phase submittal process. 4) Two crews will be used for the production piling operations. The main crew will be responsible for pile driving and progress from Unit 1 to Unit 17 without interruption. The second smaller crew will be responsible for pre-drilling and grouting. Pre-drilling will be done a maximum of one Unit in advance of the pile driving and the crew will fall back to grout the void between the pre-drilled hole and the pile no more than one unit after piling is complete for a particular Unit. 4. Crews and productions The strategic decisions made regarding the sequencing and scheduling of the work mandates the use of three crews to perform the work. Their work assignments, schedules and production rates may be summarized as follows: Alfonso: Alfonso's crew and equipment will be responsible for all operations - predrilling, driving and grouting - regarding the test piles. Their work will commence immediately after the pre-approved test piles have been procured and will continue at a rate of 2 test piles per week until all test piles are complete. The crew and equipment will be reassigned to assist with lifting and placing bridge beams once all test piles are complete. Pat: Pat's crew and equipment will be responsible for the production pile driving itself. They will start work as soon as the production piles are on site and the required pre-drilling is complete. They will start with Unit 1 and progress to Unit 17 at an uninterrupted production rate of 1 Unit every 2 weeks. This rate will require that the team work 10 shifts per week and the crew includes the resources necessary to support a night shift. This specialized high production piling crew will be reassigned to another project on completion of the work. Charlie: Charlie's crew and equipment will be responsible for the pre-drilling and grouting operations that will each take no more than 1 week to complete. Their schedule is determined by Pat's crew in that they are required to do the pre-drilling for a given Unit no more than 1 week in advance of the start of pile driving for that Unit and must complete grouting within 1 week of completion of pile driving for that Unit. This versatile utility crew will be reassigned to another phase of the project on completion of these activities. 5. Deliverables and Grading: 1. PDF or Word file including: a. WBS, including activity code (10 Points) b. Baseline schedule using (1) the critical path method (CPM) network, and (2) the schedule represented as a bar chart as shown in Table 1. (60 Points) c. Project duration (5 Points) d. Identifying the critical path (5 Points) 2. Project Presentation describing how the schedule was developed (20 Points) Table 1. Construction Schedule

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started