Answered step by step

Verified Expert Solution

Question

1 Approved Answer

John Kresge, vice president of supply chain, was very end products that fit customer specifications. In the spe- concerned as he left the meeting

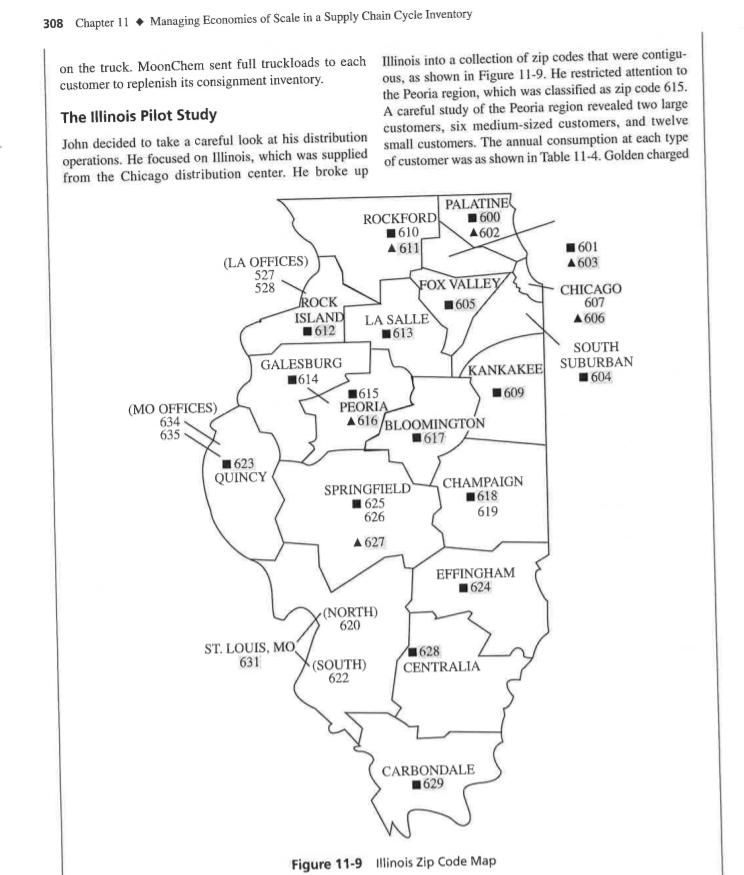

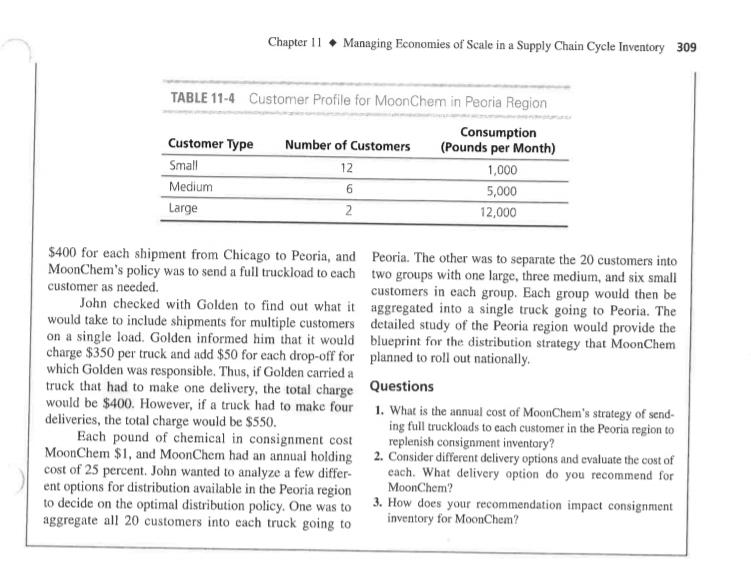

John Kresge, vice president of supply chain, was very end products that fit customer specifications. In the spe- concerned as he left the meeting at MoonChem, a manu- cialty chemicals market, MoonChem decided to differ- facturer of specialty chemicals. The year-end meeting entiate itself in the Midwest region by providing evaluated financial performance and discussed the fact consignment inventory to its customers. The company that the firm was achieving only two inventory turns a wanted to take this strategy national if it proved effec- year. A more careful look revealed that more than half the inventory MoonChem owned was in consignment with its customers. This was very surprising, given that only 20 percent of its customers carried consignment needed, and MoonChem managed replenishment to inventory. John was responsible for inventory as well as ensure availability. In most instances, consumption of transportation costs. He decided to take a careful look at chemicals by customers was stable. MoonChem owned the management of consignment inventory and come up the consignment inventories and was paid for the chemi- with an appropriate plan. tive. MoonChem kept the chemicals required by each customer in the Midwest region on consignment at the customers' sites. Customers used the chemicals as cals as they were used. MoonChem Operations Distribution at MoonChem MoonChem, a manufacturer of specialty chemicals, had MoonChem used Golden trucking, a full-truckload car- eight manufacturing plants and 40 distribution centers. rier, for all its shipments. Each truck had a capacity of The plants manufactured the base chemicals, and the 40,000 pounds; Golden charged a fixed rate given the distribution centers mixed them to produce hundreds of origin and destination, regardless of the quantity shipped 308 Chapter 11 Managing Economies of Scale in a Supply Chain Cycle Inventory on the truck. MoonChem sent full truckloads to each llinois into a collection of zip codes that were contigu- ous, as shown in Figure 11-9. He restricted attention to the Peoria region, which was classified as zip code 615. A careful study of the Peoria region revealed two large customers, six medium-sized customers, and twelve customer to replenish its consignment inventory. The Illinois Pilot Study John decided to take a careful look at his distribution small customers. The annual consumption at each type operations. He focused on Illinois, which was supplied of customer was as shown in Table 11-4. Golden charged from the Chicago distribution center. He broke up PALATINE 1600 ROCKFORD 1610 A602 A 611 1601 (LA OFFICES) A 603 527 528 ROCK ISLAND LA SALLE 1612 FOX VALLEY 1605 CHICAGO 607 A 606 1613 SOUTH GALESBURG KANKAKEE SUBURBAN 1604 1614 1615 PEORIA A616 /BLOOMINGTON 1609 (MO OFFICES) 634 635 1617 1623 QUINCY SPRINGFIELD 625 626 AMPAIGN 1618 619 A 627 EFFINGHAM 1624 (NORTH) 620 ST. LOUIS, MO 631 1628 CENTRALIA (SOUTH) 622 CARBONDALE 1629 Figure 11-9 Illinois Zip Code Map Chapter 11 Managing Economies of Scale in a Supply Chain Cycle Inventory 309 TABLE 11-4 Customer Profile for MoonChem in Peoria Region Consumption (Pounds per Month) Customer Type Number of Customers Small 12 1,000 Medium 6. 5,000 Large 2 12,000 $400 for each shipment from Chicago to Peoria, and Peoria. The other was to separate the 20 customers into MoonChem's policy was to send a full truckload to cach two groups with one large, three medium, and six small customer as needed. customers in each group. Each group would then be John checked with Golden to find out what it aggregated into a single truck going to Peoria. The would take to include shipments for multiple customers detailed study of the Peoria region would provide the on a single load. Golden informed him that it would blueprint for the distribution strategy that MoonChem charge $350 per truck and add $50 for each drop-off for planned to roll out nationally. which Golden was responsible. Thus, if Golden carried a truck that had to make one delivery, the total charge Questions would be $400. However, if a truck had to make four deliveries, the total charge would be $550. Each pound of chemical in consignment cost MoonChem $1, and MoonChem had an annual holding 2. Consider different delivery options and evaluate the cost of cost of 25 percent. John wanted to analyze a few differ- ent options for distribution available in the Peoria region to decide on the optimal distribution policy. One was to aggregate all 20 customers into cach truck going to 1. What is the annual cost of MoonChem's strategy of send- ing full truckloads to cach customer in the Peoria region to replenish consignment inventory? each. What delivery option do you recommend for MoonChem? 3. How does your recommendation impact consignment inventory for MoonChem?

Step by Step Solution

★★★★★

3.35 Rating (161 Votes )

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started