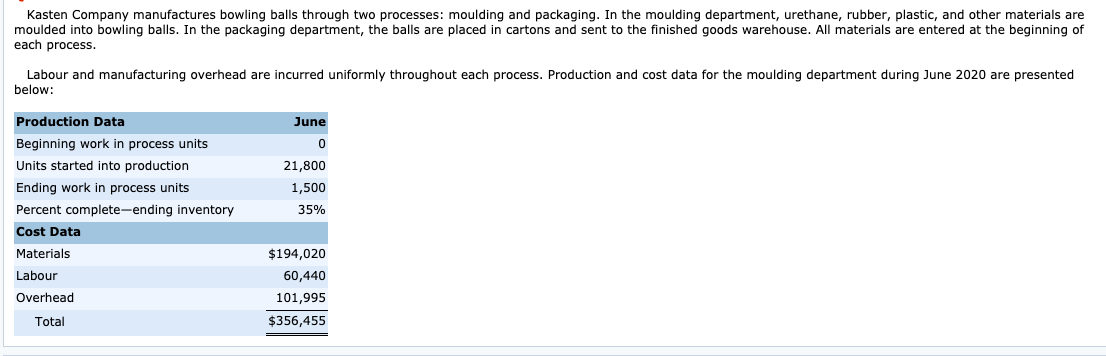

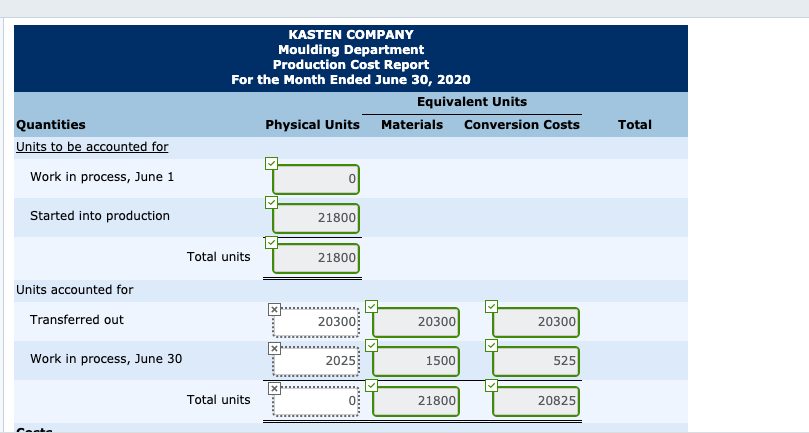

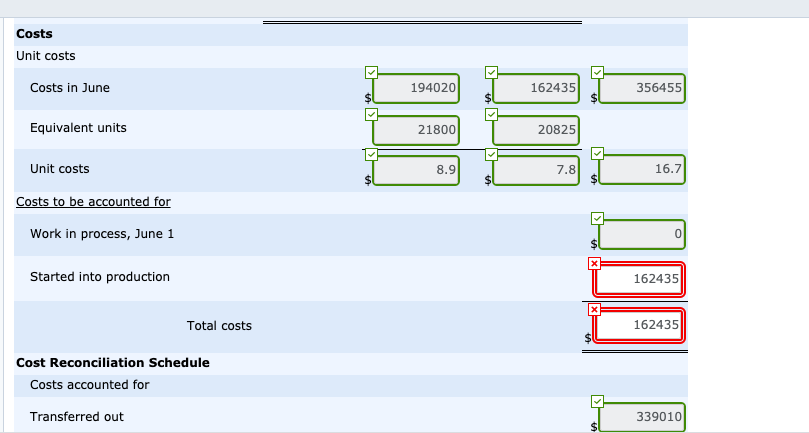

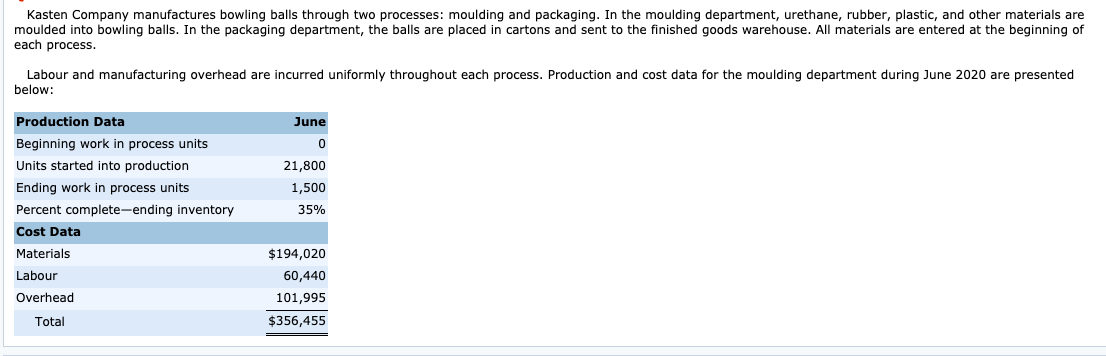

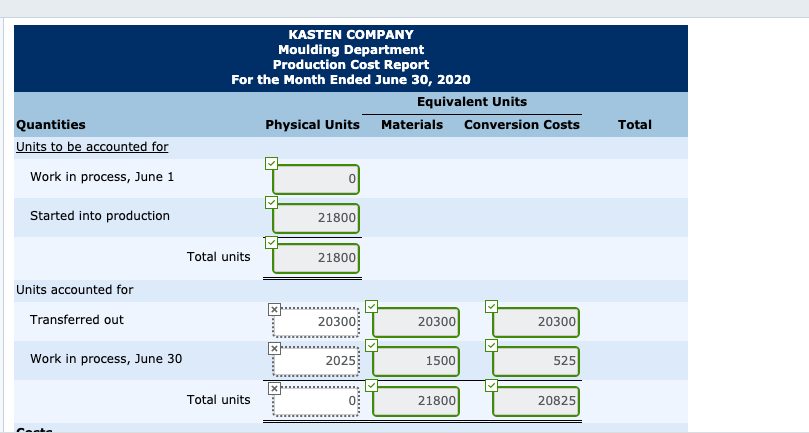

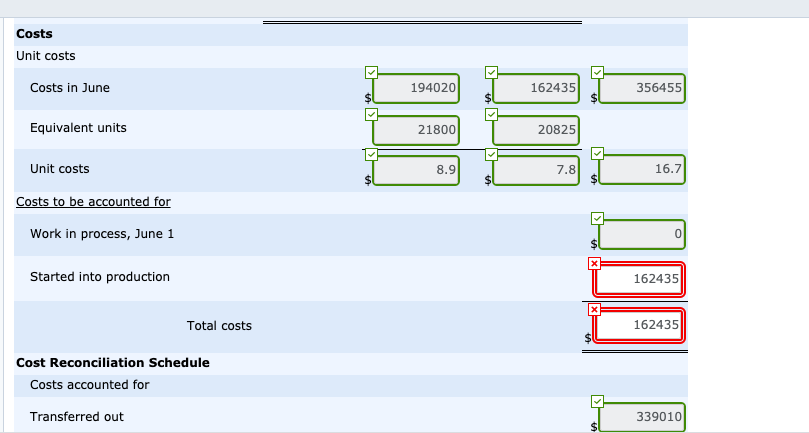

Kasten Company manufactures bowling balls through two processes: moulding and packaging. In the moulding department, urethane, rubber, plastic, and other materials are moulded into bowling balls. In the packaging department, the balls are placed in cartons and sent to the finished goods warehouse. All materials are entered at the beginning of each process. Labour and manufacturing overhead are incurred uniformly throughout each process. Production and cost data for the moulding department during June 2020 are presented below: Production Data June Beginning work in process units Units started into production 21,800 Ending work in process units 1,500 Percent complete-ending inventory 35% Cost Data Materials $194,020 Labour 60,440 Overhead 101,995 $356,455 Total KASTEN COMPANY Moulding Department Production Cost Report For the Month Ended June 30, 2020 Equivalent Units Total Quantities Physical Units Materials Conversion Costs Units to be accounted for Work in process, June 1 Started into production 21800 Total units 21800 Units accounted for Transferred out 20300 20300 20300 Work in process, June 30 2025 1500 525 Total units 21800 20825 X...x.... Costs Unit costs 162435 356455 Costs in June 194020 Equivalent units 21800 20825 16.7 Unit costs 8.9 7.8 Costs to be accounted for Work in process, June 1 Started into production 162435 Total costs 162435 Cost Reconciliation Schedule Costs accounted for Transferred out 339010 Kasten Company manufactures bowling balls through two processes: moulding and packaging. In the moulding department, urethane, rubber, plastic, and other materials are moulded into bowling balls. In the packaging department, the balls are placed in cartons and sent to the finished goods warehouse. All materials are entered at the beginning of each process. Labour and manufacturing overhead are incurred uniformly throughout each process. Production and cost data for the moulding department during June 2020 are presented below: Production Data June Beginning work in process units Units started into production 21,800 Ending work in process units 1,500 Percent complete-ending inventory 35% Cost Data Materials $194,020 Labour 60,440 Overhead 101,995 $356,455 Total KASTEN COMPANY Moulding Department Production Cost Report For the Month Ended June 30, 2020 Equivalent Units Total Quantities Physical Units Materials Conversion Costs Units to be accounted for Work in process, June 1 Started into production 21800 Total units 21800 Units accounted for Transferred out 20300 20300 20300 Work in process, June 30 2025 1500 525 Total units 21800 20825 X...x.... Costs Unit costs 162435 356455 Costs in June 194020 Equivalent units 21800 20825 16.7 Unit costs 8.9 7.8 Costs to be accounted for Work in process, June 1 Started into production 162435 Total costs 162435 Cost Reconciliation Schedule Costs accounted for Transferred out 339010