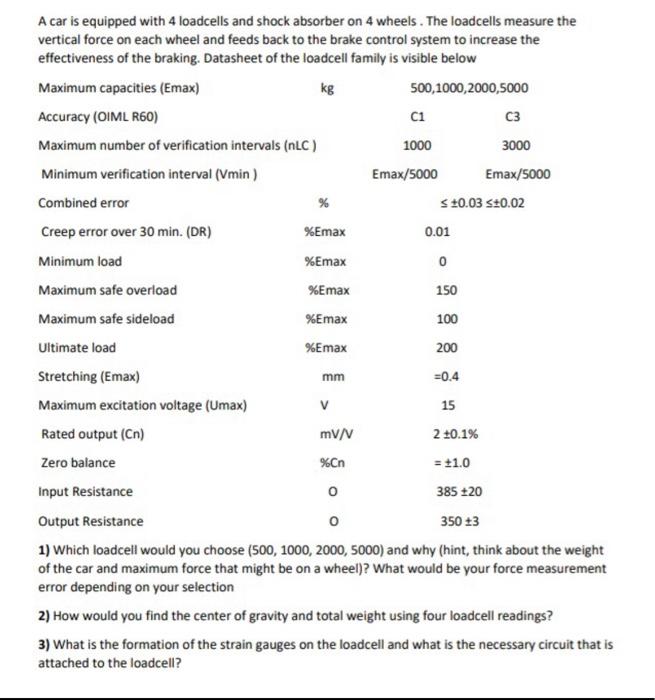

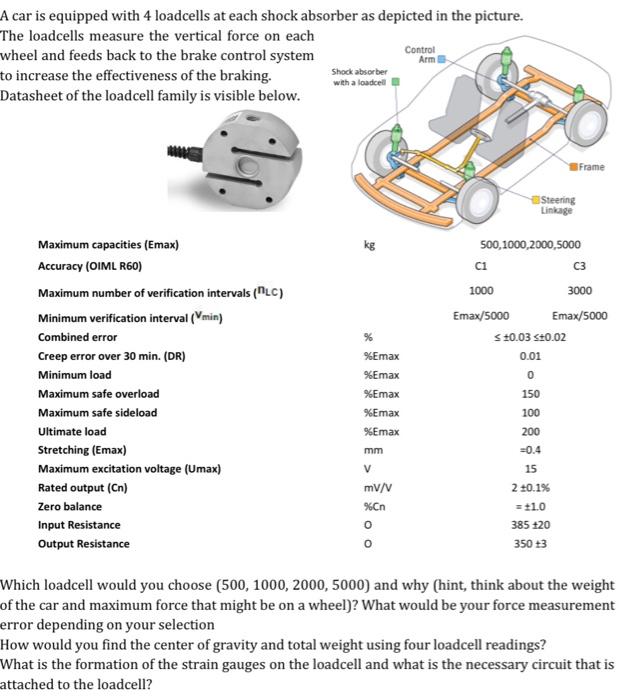

kg C3 A car is equipped with 4 loadcells and shock absorber on 4 wheels. The loadcells measure the vertical force on each wheel and feeds back to the brake control system to increase the effectiveness of the braking. Datasheet of the loadcell family is visible below Maximum capacities (Emax) 500,1000,2000,5000 Accuracy (OIML R60) c1 Maximum number of verification intervals (LC) 1000 3000 Minimum verification interval (Vmin) Emax/5000 Emax/5000 Combined error % St0.03 0.02 Creep error over 30 min. (DR) %Emax 0.01 Minimum load %Emax 0 Maximum safe overload %Emax 150 Maximum safe sideload %Emax 100 Ultimate load %Emax 200 Stretching (Emax) mm =0.4 Maximum excitation voltage (Umax) v 15 Rated output (Cn) mVN 2 0.1% Zero balance %Cn = $1.0 Input Resistance o 385 +20 Output Resistance 350 13 1) Which loadcell would you choose (500, 1000, 2000, 5000) and why (hint think about the weight of the car and maximum force that might be on a wheel)? What would be your force measurement error depending on your selection 2) How would you find the center of gravity and total weight using four loadcell readings? 3) What is the formation of the strain gauges on the loadcell and what is the necessary circuit that is attached to the loadcell? A car is equipped with 4 loadcells at each shock absorber as depicted in the picture. The loadcells measure the vertical force on each wheel and feeds back to the brake control system to increase the effectiveness of the braking. Shock absorber Datasheet of the loadcell family is visible below. Control Arm with a loadcell Frame Steering Linkage kg Maximum capacities (Emax) Accuracy (OIML R60) Maximum number of verification intervals (c) Minimum verification interval (Vmin) Combined error Creep error over 30 min. (DR) Minimum load Maximum safe overload Maximum safe sideload Ultimate load Stretching (Emax) Maximum excitation voltage (Umax) Rated output (Cn) Zero balance Input Resistance Output Resistance % %Emax %Emax %Emax %Emax %Emax 500,1000,2000,5000 C1 c 1000 3000 Emax/5000 Emax/5000 S 10.03 0.02 0.01 o 150 100 200 mm =0.4 v mV/V %Cn o 15 2 20.1% = 11.0 385 120 350 13 Which loadcell would you choose (500, 1000, 2000, 5000) and why (hint, think about the weight of the car and maximum force that might be on a wheel)? What would be your force measurement error depending on your selection How would you find the center of gravity and total weight using four loadcell readings? What is the formation of the strain gauges on the loadcell and what is the necessary circuit that is attached to the loadcell? kg C3 A car is equipped with 4 loadcells and shock absorber on 4 wheels. The loadcells measure the vertical force on each wheel and feeds back to the brake control system to increase the effectiveness of the braking. Datasheet of the loadcell family is visible below Maximum capacities (Emax) 500,1000,2000,5000 Accuracy (OIML R60) c1 Maximum number of verification intervals (LC) 1000 3000 Minimum verification interval (Vmin) Emax/5000 Emax/5000 Combined error % St0.03 0.02 Creep error over 30 min. (DR) %Emax 0.01 Minimum load %Emax 0 Maximum safe overload %Emax 150 Maximum safe sideload %Emax 100 Ultimate load %Emax 200 Stretching (Emax) mm =0.4 Maximum excitation voltage (Umax) v 15 Rated output (Cn) mVN 2 0.1% Zero balance %Cn = $1.0 Input Resistance o 385 +20 Output Resistance 350 13 1) Which loadcell would you choose (500, 1000, 2000, 5000) and why (hint think about the weight of the car and maximum force that might be on a wheel)? What would be your force measurement error depending on your selection 2) How would you find the center of gravity and total weight using four loadcell readings? 3) What is the formation of the strain gauges on the loadcell and what is the necessary circuit that is attached to the loadcell? A car is equipped with 4 loadcells at each shock absorber as depicted in the picture. The loadcells measure the vertical force on each wheel and feeds back to the brake control system to increase the effectiveness of the braking. Shock absorber Datasheet of the loadcell family is visible below. Control Arm with a loadcell Frame Steering Linkage kg Maximum capacities (Emax) Accuracy (OIML R60) Maximum number of verification intervals (c) Minimum verification interval (Vmin) Combined error Creep error over 30 min. (DR) Minimum load Maximum safe overload Maximum safe sideload Ultimate load Stretching (Emax) Maximum excitation voltage (Umax) Rated output (Cn) Zero balance Input Resistance Output Resistance % %Emax %Emax %Emax %Emax %Emax 500,1000,2000,5000 C1 c 1000 3000 Emax/5000 Emax/5000 S 10.03 0.02 0.01 o 150 100 200 mm =0.4 v mV/V %Cn o 15 2 20.1% = 11.0 385 120 350 13 Which loadcell would you choose (500, 1000, 2000, 5000) and why (hint, think about the weight of the car and maximum force that might be on a wheel)? What would be your force measurement error depending on your selection How would you find the center of gravity and total weight using four loadcell readings? What is the formation of the strain gauges on the loadcell and what is the necessary circuit that is attached to the loadcell