Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Larsen Company manufactures car seats in its Chicago plant. Each car seat passes through the assembly department and the testing department. This problem focuses on

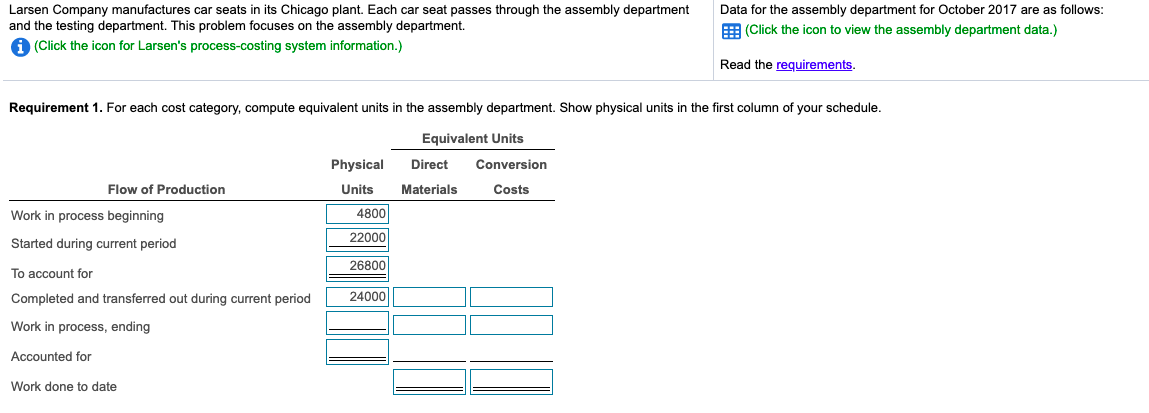

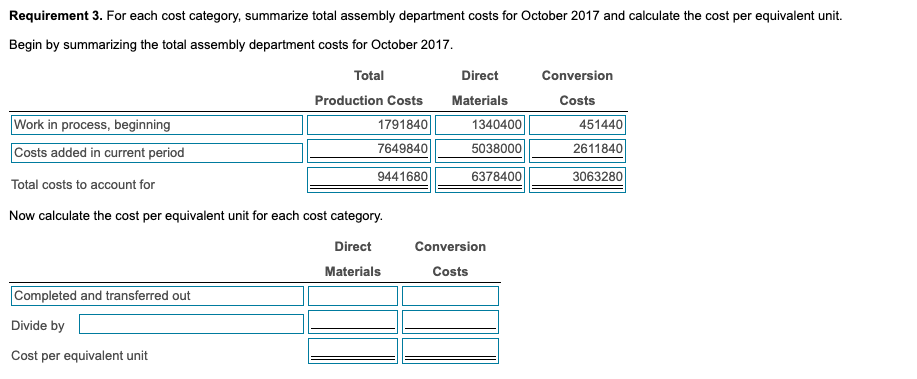

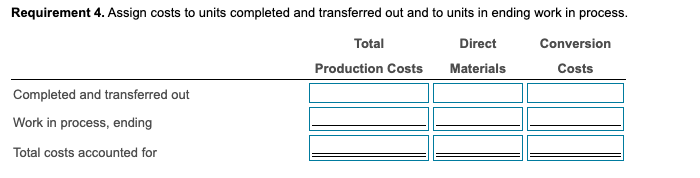

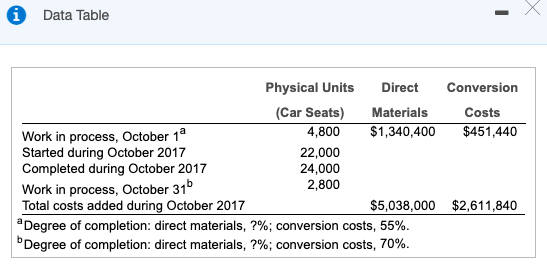

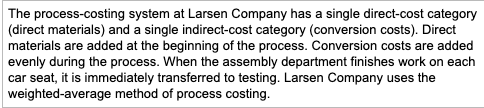

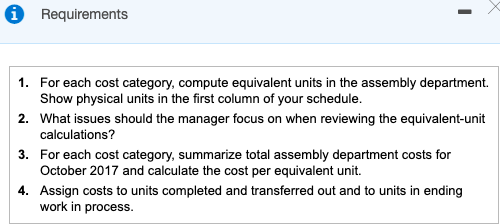

Larsen Company manufactures car seats in its Chicago plant. Each car seat passes through the assembly department and the testing department. This problem focuses on the assembly department. (Click the icon for Larsen's process-costing system information.) Data for the assembly department for October 2017 are as follows: (Click the icon to view the assembly department data.) Read the requirements. Requirement 1. For each cost category, compute equivalent units in the assembly department. Show physical units in the first column of your schedule. Equivalent Units Direct Conversion Physical Units Flow of Production Materials Costs 4800 Work in process beginning Started during current period 22000 26800 To account for Completed and transferred out during current period Work in process, ending 24000 Accounted for Work done to date Requirement 3. For each cost category, summarize total assembly department costs for October 2017 and calculate the cost per equivalent unit. Begin by summarizing the total assembly department costs for October 2017. Total Direct Conversion Production Costs Materials Costs Work in process, beginning 1791840 1340400 451440 Costs added in current period 7649840 5038000 2611840 9441680 6378400 3063280 Total costs to account for Now calculate the cost per equivalent unit for each cost category. Direct Conversion Materials Costs Completed and transferred out Divide by Cost per equivalent unit Requirement 4. Assign costs to units completed and transferred out and to units in ending work in process. Total Direct Conversion Production Costs Materials Costs Completed and transferred out Work in process, ending Total costs accounted for Data Table Physical Units Direct Conversion (Car Seats) Materials Costs Work in process, October 18 4,800 $1,340,400 $451,440 Started during October 2017 22,000 Completed during October 2017 24,000 Work in process, October 31b 2,800 Total costs added during October 2017 $5,038,000 $2,611,840 Degree of completion: direct materials, %; conversion costs, 55%. Degree of completion: direct materials, 2%; conversion costs, 70%. b The process-costing system at Larsen Company has a single direct-cost category (direct materials) and a single indirect-cost category (conversion costs). Direct materials are added at the beginning of the process. Conversion costs are added evenly during the process. When the assembly department finishes work on each car seat, it is immediately transferred to testing. Larsen Company uses the weighted average method of process costing. 0 Requirements 1. For each cost category, compute equivalent units in the assembly department. Show physical units in the first column of your schedule. 2. What issues should the manager focus on when reviewing the equivalent-unit calculations? 3. For each cost category, summarize total assembly department costs for October 2017 and calculate the cost per equivalent unit. 4. Assign costs to units completed and transferred out and to units in ending work in process

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started