Answered step by step

Verified Expert Solution

Question

1 Approved Answer

In this exercise, you will be working as a transport planner for the company Visstick BV' in Apeldoorn (NB: postcode 7314). The company Visstick

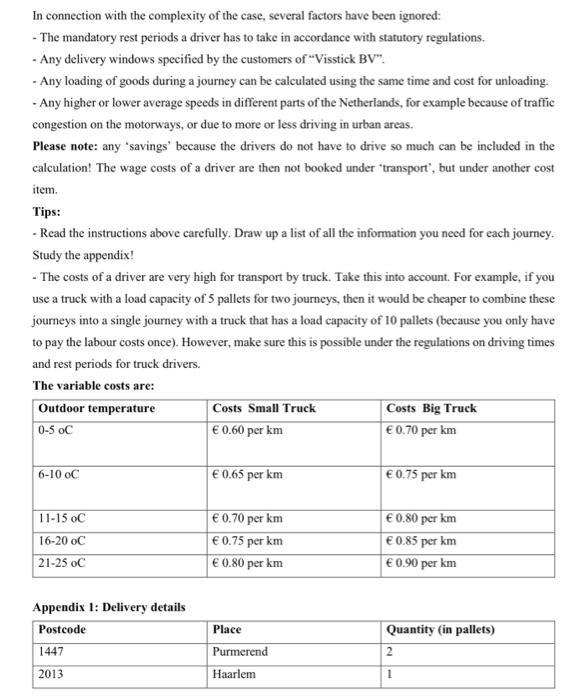

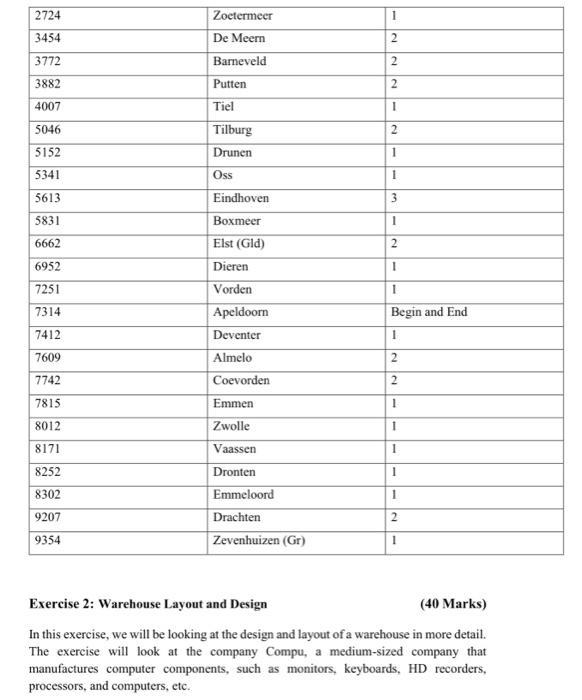

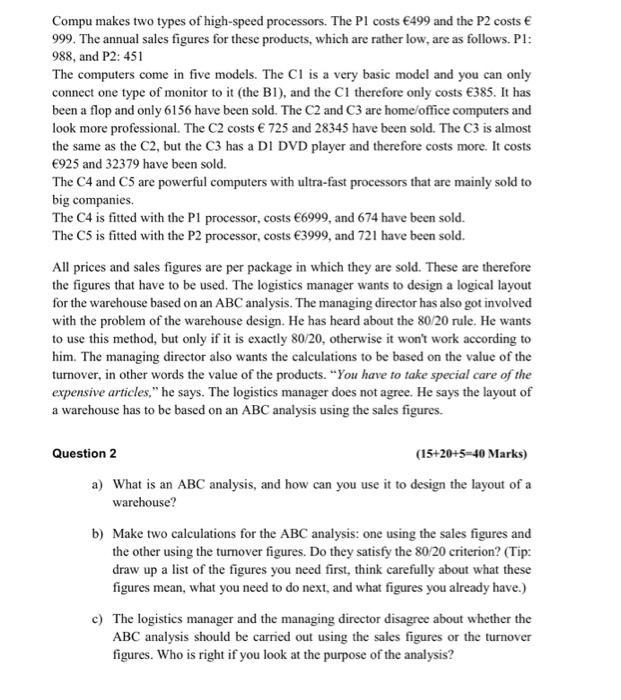

In this exercise, you will be working as a transport planner for the company "Visstick BV' in Apeldoorn (NB: postcode 7314). The company Visstick BV is a wholesaler in frozen fish fingers. The products have to be delivered in refrigerated trucks. The hotter the weather, the more energy it takes to keep the products cold. The variable costs therefore go up when the outdoor temperature goes up. The customers of Visstick BV get their goods delivered in whole pallets. Visstick BV transports the products to the customers itself. They use a very large and modern fleet of delivery vehicles for this. They have 4 trucks that can carry up to 10 pallets and 2 trucks that can carry up to 6 pallets. The company has six full-time drivers, who can be assigned to work in the warchouse or the production department when they do not have to drive. Because business is going so well, Visstick BV has been granted an exemption under the regulations on driving times and rest periods for truck drivers by the National Vehicle and Driving Licence Registration Authority (RDW). As compensation for having to work longer hours, the drivers get 10 extra days holiday. Furthermore, the employer wants the trucks to be loaded at night time so they are ready to leave at 07.00 hours the following morning. Although the trucks are very new, the trucks can only drive at an average speed of 60 km per hour. The costs of the trucks per km are variable (including diesel fuel, servicing, etc.). The fixed costs for a small truck are 35 per work day and for a big truck 50 per work day (including interest, depreciation, insurance, motor vehicle tax etc.). The drivers cost 30 per hour, and the rest periods are paid. The drivers have to unload the cargo themselves, which takes on average 10 minutes per pallet. The company has asked the NHTV if some of its students can draw up a planning schedule. For this exercise, we will use the figures for a day in September when the temperature is "13 oC". The information provided by "Visstick" is included in the appendix. Question 1: Make a planning schedule so that the journeys can be made to all the customers (listed in Appendix 1) at the lowest possible cost. In connection with the complexity of the case, several factors have been ignored: - The mandatory rest periods a driver has to take in accordance with statutory regulations. - Any delivery windows specified by the customers of "Visstick BV". - Any loading of goods during a journey can be calculated using the same time and cost for unloading. - Any higher or lower average speeds in different parts of the Netherlands, for example because of traffic congestion on the motorways, or due to more or less driving in urban areas. Please note: any 'savings' because the drivers do not have to drive so much can be included in the calculation! The wage costs of a driver are then not booked under "transport', but under another cost item. Tips: - Read the instructions above carefully. Draw up a list of all the information you need for cach journey. Study the appendix! - The costs of a driver are very high for transport by truck. Take this into account. For example, if you use a truck with a load capacity of 5 pallets for two journeys, then it would be cheaper to combine these journeys into a single journey with a truck that has a load capacity of 10 pallets (because you only have to pay the labour costs once). However, make sure this is possible under the regulations on driving times and rest periods for truck drivers. The variable costs are: Costs Small Truck 0.60 per km Costs Big Truck 0.70 per km Outdoor temperature 0-5 oC 6-10 oC 0.65 per km 0.75 r km 0.70 per km 0.75 per km 0.80 per km 0.80 per km 0.85 per km 0.90 per km 11-15 oC 16-20 oC 21-25 oC Appendix 1: Delivery details Postcode Place Quantity (in pallets) 1447 Purmerend 2 2013 Haarlem Zoetermeer De Meern 2724 3454 3772 Barneveld 3882 Putten 4007 Tiel 5046 Tilburg 5152 Drunen 5341 Os 5613 Eindhoven 5831 Boxmeer Elst (Gld) Dieren 6662 6952 7251 Vorden 7314 Apeldoorn Begin and End 7412 Deventer 7609 Almelo 7742 Coevorden 2 7815 Emmen 8012 Zwolle 8171 Vaassen 8252 Dronten 8302 Emmeloord 9207 Drachten 9354 Zevenhuizen (Gr) Exercise 2: Warehouse Layout and Design (40 Marks) In this exercise, we will be looking at the design and layout of a warehouse in more detail. The exercise will look at the company Compu, a medium-sized company that manufactures computer components, such as monitors, keyboards, HD recorders, processors, and computers, etc. They make different versions of most of their products, so that cach product comes in a BI, B2, and B3 version. This same applies for the other products. Just like many other small and medium-sized companies, the warchouse manager decides where the articles have to be stored. There is not a fixed procedure or system for this. This means that order pickers often have trouble finding a product and have to go and find the warehouse manager to ask him where it is. Sometimes the same products are put in different places around the warehouse. Consequently, when one pallet is empty, the order picker has to go to the other side of the warehouse to complete the order. Up until now, this situation has never caused any major problems. The warehouse manager has everything under control and there are hardly ever any errors in the deliveries. Nonetheless, the logistics manager is very concerned that this system will eventually cause big problems in the future. He is concerned for two reasons. First of all, the warehouse manager is over the age of 60. It won't be long before he will retire. The warehouse manager is often the only one who knows exactly what, how much, and where everything is in warehouse. When he retires, all that knowledge will be lost. The warchouse manager was not at work last week because he was ill, and the warchouse workers had to call him up several times a day. The second reason is the growing demand for the products of Compu. The logistics manager is afraid that if the company continues to grow, then it will be impossible for just one man to keep track of all the stock information. The logistics manager and the managing director expect to see a sharp rise in sales as early as this summer. In order to prepare for these eventualities, the logistics manager starts to work out a solution in June. He wants to organize the warehouse in a different way so the order pickers don't get in each other's way, and above all to make sure they have to travel the shortest possible distance. He can use the following data for this. There are three types of monitors: B1, B2 and B3. B1 costs 185, B2 costs 300, and B3 costs 250. The sales figures for these flat screen monitors are as follows. B2: 10728, and B3: 4344. BI: 19235, The keyboards are manufactured in two types (one wired and one wireless): TI and T2. The T1 costs 49 and the T2 costs 149. The sales figures for the keyboards are as follows. TI: 35781, T2: 14567. The HD DVD players are available in three types. The DI costs 195 and 5910 have been sold, the D2 costs 295 and 1415 have been sold. The D3 is almost the same as the D2, but with the D3 you can burn your own DVDS as well. The D3 costs 999 and 233 have been sold. Compu makes two types of high-speed processors. The Pl costs 499 and the P2 costs 999. The annual sales figures for these products, which are rather low, are as follows. Pl: 988, and P2: 451 The computers come in five models. The Cl is a very basic model and you can only connect one type of monitor to it (the BI), and the Cl therefore only costs 385. It has been a flop and only 6156 have been sold. The C2 and C3 are home/office computers and look more professional. The C2 costs 725 and 28345 have been sold. The C3 is almost the same as the C2, but the C3 has a DI DVD player and therefore costs more. It costs 925 and 32379 have been sold. The C4 and C5 are powerful computers with ultra-fast processors that are mainly sold to big companies. The C4 is fitted with the Pl processor, costs 6999, and 674 have been sold. The C5 is fitted with the P2 processor, costs 3999, and 721 have been sold. All prices and sales figures are per package in which they are sold. These are therefore the figures that have to be used. The logistics manager wants to design a logical layout for the warehouse based on an ABC analysis. The managing director has also got involved with the problem of the warehouse design. He has heard about the 80/20 rule. He wants to use this method, but only if it is exactly 80/20, otherwise it won't work according to him. The managing director also wants the calculations to be based on the value of the turnover, in other words the value of the products. "You have to take special care of the expensive articles," he says. The logistics manager does not agree. He says the layout of a warehouse has to be based on an ABC analysis using the sales figures. Question 2 (15+20+5-40 Marks) a) What is an ABC analysis, and how can you use it to design the layout of a warehouse? b) Make two calculations for the ABC analysis: one using the sales figures and the other using the turnover figures. Do they satisfy the 80/20 criterion? (Tip: draw up a list of the figures you need first, think carefully about what these figures mean, what you need to do next, and what figures you already have.) c) The logistics manager and the managing director disagree about whether the ABC analysis should be carried out using the sales figures or the turnover figures. Who is right if you look at the purpose of the analysis? In this exercise, you will be working as a transport planner for the company "Visstick BV' in Apeldoorn (NB: postcode 7314). The company Visstick BV is a wholesaler in frozen fish fingers. The products have to be delivered in refrigerated trucks. The hotter the weather, the more energy it takes to keep the products cold. The variable costs therefore go up when the outdoor temperature goes up. The customers of Visstick BV get their goods delivered in whole pallets. Visstick BV transports the products to the customers itself. They use a very large and modern fleet of delivery vehicles for this. They have 4 trucks that can carry up to 10 pallets and 2 trucks that can carry up to 6 pallets. The company has six full-time drivers, who can be assigned to work in the warchouse or the production department when they do not have to drive. Because business is going so well, Visstick BV has been granted an exemption under the regulations on driving times and rest periods for truck drivers by the National Vehicle and Driving Licence Registration Authority (RDW). As compensation for having to work longer hours, the drivers get 10 extra days holiday. Furthermore, the employer wants the trucks to be loaded at night time so they are ready to leave at 07.00 hours the following morning. Although the trucks are very new, the trucks can only drive at an average speed of 60 km per hour. The costs of the trucks per km are variable (including diesel fuel, servicing, etc.). The fixed costs for a small truck are 35 per work day and for a big truck 50 per work day (including interest, depreciation, insurance, motor vehicle tax etc.). The drivers cost 30 per hour, and the rest periods are paid. The drivers have to unload the cargo themselves, which takes on average 10 minutes per pallet. The company has asked the NHTV if some of its students can draw up a planning schedule. For this exercise, we will use the figures for a day in September when the temperature is "13 oC". The information provided by "Visstick" is included in the appendix. Question 1: Make a planning schedule so that the journeys can be made to all the customers (listed in Appendix 1) at the lowest possible cost. In connection with the complexity of the case, several factors have been ignored: - The mandatory rest periods a driver has to take in accordance with statutory regulations. - Any delivery windows specified by the customers of "Visstick BV". - Any loading of goods during a journey can be calculated using the same time and cost for unloading. - Any higher or lower average speeds in different parts of the Netherlands, for example because of traffic congestion on the motorways, or due to more or less driving in urban areas. Please note: any 'savings' because the drivers do not have to drive so much can be included in the calculation! The wage costs of a driver are then not booked under "transport', but under another cost item. Tips: - Read the instructions above carefully. Draw up a list of all the information you need for cach journey. Study the appendix! - The costs of a driver are very high for transport by truck. Take this into account. For example, if you use a truck with a load capacity of 5 pallets for two journeys, then it would be cheaper to combine these journeys into a single journey with a truck that has a load capacity of 10 pallets (because you only have to pay the labour costs once). However, make sure this is possible under the regulations on driving times and rest periods for truck drivers. The variable costs are: Costs Small Truck 0.60 per km Costs Big Truck 0.70 per km Outdoor temperature 0-5 oC 6-10 oC 0.65 per km 0.75 r km 0.70 per km 0.75 per km 0.80 per km 0.80 per km 0.85 per km 0.90 per km 11-15 oC 16-20 oC 21-25 oC Appendix 1: Delivery details Postcode Place Quantity (in pallets) 1447 Purmerend 2 2013 Haarlem Zoetermeer De Meern 2724 3454 3772 Barneveld 3882 Putten 4007 Tiel 5046 Tilburg 5152 Drunen 5341 Os 5613 Eindhoven 5831 Boxmeer Elst (Gld) Dieren 6662 6952 7251 Vorden 7314 Apeldoorn Begin and End 7412 Deventer 7609 Almelo 7742 Coevorden 2 7815 Emmen 8012 Zwolle 8171 Vaassen 8252 Dronten 8302 Emmeloord 9207 Drachten 9354 Zevenhuizen (Gr) Exercise 2: Warehouse Layout and Design (40 Marks) In this exercise, we will be looking at the design and layout of a warehouse in more detail. The exercise will look at the company Compu, a medium-sized company that manufactures computer components, such as monitors, keyboards, HD recorders, processors, and computers, etc. They make different versions of most of their products, so that cach product comes in a BI, B2, and B3 version. This same applies for the other products. Just like many other small and medium-sized companies, the warchouse manager decides where the articles have to be stored. There is not a fixed procedure or system for this. This means that order pickers often have trouble finding a product and have to go and find the warehouse manager to ask him where it is. Sometimes the same products are put in different places around the warehouse. Consequently, when one pallet is empty, the order picker has to go to the other side of the warehouse to complete the order. Up until now, this situation has never caused any major problems. The warehouse manager has everything under control and there are hardly ever any errors in the deliveries. Nonetheless, the logistics manager is very concerned that this system will eventually cause big problems in the future. He is concerned for two reasons. First of all, the warehouse manager is over the age of 60. It won't be long before he will retire. The warehouse manager is often the only one who knows exactly what, how much, and where everything is in warehouse. When he retires, all that knowledge will be lost. The warchouse manager was not at work last week because he was ill, and the warchouse workers had to call him up several times a day. The second reason is the growing demand for the products of Compu. The logistics manager is afraid that if the company continues to grow, then it will be impossible for just one man to keep track of all the stock information. The logistics manager and the managing director expect to see a sharp rise in sales as early as this summer. In order to prepare for these eventualities, the logistics manager starts to work out a solution in June. He wants to organize the warehouse in a different way so the order pickers don't get in each other's way, and above all to make sure they have to travel the shortest possible distance. He can use the following data for this. There are three types of monitors: B1, B2 and B3. B1 costs 185, B2 costs 300, and B3 costs 250. The sales figures for these flat screen monitors are as follows. B2: 10728, and B3: 4344. BI: 19235, The keyboards are manufactured in two types (one wired and one wireless): TI and T2. The T1 costs 49 and the T2 costs 149. The sales figures for the keyboards are as follows. TI: 35781, T2: 14567. The HD DVD players are available in three types. The DI costs 195 and 5910 have been sold, the D2 costs 295 and 1415 have been sold. The D3 is almost the same as the D2, but with the D3 you can burn your own DVDS as well. The D3 costs 999 and 233 have been sold. Compu makes two types of high-speed processors. The Pl costs 499 and the P2 costs 999. The annual sales figures for these products, which are rather low, are as follows. Pl: 988, and P2: 451 The computers come in five models. The Cl is a very basic model and you can only connect one type of monitor to it (the BI), and the Cl therefore only costs 385. It has been a flop and only 6156 have been sold. The C2 and C3 are home/office computers and look more professional. The C2 costs 725 and 28345 have been sold. The C3 is almost the same as the C2, but the C3 has a DI DVD player and therefore costs more. It costs 925 and 32379 have been sold. The C4 and C5 are powerful computers with ultra-fast processors that are mainly sold to big companies. The C4 is fitted with the Pl processor, costs 6999, and 674 have been sold. The C5 is fitted with the P2 processor, costs 3999, and 721 have been sold. All prices and sales figures are per package in which they are sold. These are therefore the figures that have to be used. The logistics manager wants to design a logical layout for the warehouse based on an ABC analysis. The managing director has also got involved with the problem of the warehouse design. He has heard about the 80/20 rule. He wants to use this method, but only if it is exactly 80/20, otherwise it won't work according to him. The managing director also wants the calculations to be based on the value of the turnover, in other words the value of the products. "You have to take special care of the expensive articles," he says. The logistics manager does not agree. He says the layout of a warehouse has to be based on an ABC analysis using the sales figures. Question 2 (15+20+5-40 Marks) a) What is an ABC analysis, and how can you use it to design the layout of a warehouse? b) Make two calculations for the ABC analysis: one using the sales figures and the other using the turnover figures. Do they satisfy the 80/20 criterion? (Tip: draw up a list of the figures you need first, think carefully about what these figures mean, what you need to do next, and what figures you already have.) c) The logistics manager and the managing director disagree about whether the ABC analysis should be carried out using the sales figures or the turnover figures. Who is right if you look at the purpose of the analysis? In this exercise, you will be working as a transport planner for the company "Visstick BV' in Apeldoorn (NB: postcode 7314). The company Visstick BV is a wholesaler in frozen fish fingers. The products have to be delivered in refrigerated trucks. The hotter the weather, the more energy it takes to keep the products cold. The variable costs therefore go up when the outdoor temperature goes up. The customers of Visstick BV get their goods delivered in whole pallets. Visstick BV transports the products to the customers itself. They use a very large and modern fleet of delivery vehicles for this. They have 4 trucks that can carry up to 10 pallets and 2 trucks that can carry up to 6 pallets. The company has six full-time drivers, who can be assigned to work in the warchouse or the production department when they do not have to drive. Because business is going so well, Visstick BV has been granted an exemption under the regulations on driving times and rest periods for truck drivers by the National Vehicle and Driving Licence Registration Authority (RDW). As compensation for having to work longer hours, the drivers get 10 extra days holiday. Furthermore, the employer wants the trucks to be loaded at night time so they are ready to leave at 07.00 hours the following morning. Although the trucks are very new, the trucks can only drive at an average speed of 60 km per hour. The costs of the trucks per km are variable (including diesel fuel, servicing, etc.). The fixed costs for a small truck are 35 per work day and for a big truck 50 per work day (including interest, depreciation, insurance, motor vehicle tax etc.). The drivers cost 30 per hour, and the rest periods are paid. The drivers have to unload the cargo themselves, which takes on average 10 minutes per pallet. The company has asked the NHTV if some of its students can draw up a planning schedule. For this exercise, we will use the figures for a day in September when the temperature is "13 oC". The information provided by "Visstick" is included in the appendix. Question 1: Make a planning schedule so that the journeys can be made to all the customers (listed in Appendix 1) at the lowest possible cost. In connection with the complexity of the case, several factors have been ignored: - The mandatory rest periods a driver has to take in accordance with statutory regulations. - Any delivery windows specified by the customers of "Visstick BV". - Any loading of goods during a journey can be calculated using the same time and cost for unloading. - Any higher or lower average speeds in different parts of the Netherlands, for example because of traffic congestion on the motorways, or due to more or less driving in urban areas. Please note: any 'savings' because the drivers do not have to drive so much can be included in the calculation! The wage costs of a driver are then not booked under "transport', but under another cost item. Tips: - Read the instructions above carefully. Draw up a list of all the information you need for cach journey. Study the appendix! - The costs of a driver are very high for transport by truck. Take this into account. For example, if you use a truck with a load capacity of 5 pallets for two journeys, then it would be cheaper to combine these journeys into a single journey with a truck that has a load capacity of 10 pallets (because you only have to pay the labour costs once). However, make sure this is possible under the regulations on driving times and rest periods for truck drivers. The variable costs are: Costs Small Truck 0.60 per km Costs Big Truck 0.70 per km Outdoor temperature 0-5 oC 6-10 oC 0.65 per km 0.75 r km 0.70 per km 0.75 per km 0.80 per km 0.80 per km 0.85 per km 0.90 per km 11-15 oC 16-20 oC 21-25 oC Appendix 1: Delivery details Postcode Place Quantity (in pallets) 1447 Purmerend 2 2013 Haarlem Zoetermeer De Meern 2724 3454 3772 Barneveld 3882 Putten 4007 Tiel 5046 Tilburg 5152 Drunen 5341 Os 5613 Eindhoven 5831 Boxmeer Elst (Gld) Dieren 6662 6952 7251 Vorden 7314 Apeldoorn Begin and End 7412 Deventer 7609 Almelo 7742 Coevorden 2 7815 Emmen 8012 Zwolle 8171 Vaassen 8252 Dronten 8302 Emmeloord 9207 Drachten 9354 Zevenhuizen (Gr) Exercise 2: Warehouse Layout and Design (40 Marks) In this exercise, we will be looking at the design and layout of a warehouse in more detail. The exercise will look at the company Compu, a medium-sized company that manufactures computer components, such as monitors, keyboards, HD recorders, processors, and computers, etc. They make different versions of most of their products, so that cach product comes in a BI, B2, and B3 version. This same applies for the other products. Just like many other small and medium-sized companies, the warchouse manager decides where the articles have to be stored. There is not a fixed procedure or system for this. This means that order pickers often have trouble finding a product and have to go and find the warehouse manager to ask him where it is. Sometimes the same products are put in different places around the warehouse. Consequently, when one pallet is empty, the order picker has to go to the other side of the warehouse to complete the order. Up until now, this situation has never caused any major problems. The warehouse manager has everything under control and there are hardly ever any errors in the deliveries. Nonetheless, the logistics manager is very concerned that this system will eventually cause big problems in the future. He is concerned for two reasons. First of all, the warehouse manager is over the age of 60. It won't be long before he will retire. The warehouse manager is often the only one who knows exactly what, how much, and where everything is in warehouse. When he retires, all that knowledge will be lost. The warchouse manager was not at work last week because he was ill, and the warchouse workers had to call him up several times a day. The second reason is the growing demand for the products of Compu. The logistics manager is afraid that if the company continues to grow, then it will be impossible for just one man to keep track of all the stock information. The logistics manager and the managing director expect to see a sharp rise in sales as early as this summer. In order to prepare for these eventualities, the logistics manager starts to work out a solution in June. He wants to organize the warehouse in a different way so the order pickers don't get in each other's way, and above all to make sure they have to travel the shortest possible distance. He can use the following data for this. There are three types of monitors: B1, B2 and B3. B1 costs 185, B2 costs 300, and B3 costs 250. The sales figures for these flat screen monitors are as follows. B2: 10728, and B3: 4344. BI: 19235, The keyboards are manufactured in two types (one wired and one wireless): TI and T2. The T1 costs 49 and the T2 costs 149. The sales figures for the keyboards are as follows. TI: 35781, T2: 14567. The HD DVD players are available in three types. The DI costs 195 and 5910 have been sold, the D2 costs 295 and 1415 have been sold. The D3 is almost the same as the D2, but with the D3 you can burn your own DVDS as well. The D3 costs 999 and 233 have been sold. Compu makes two types of high-speed processors. The Pl costs 499 and the P2 costs 999. The annual sales figures for these products, which are rather low, are as follows. Pl: 988, and P2: 451 The computers come in five models. The Cl is a very basic model and you can only connect one type of monitor to it (the BI), and the Cl therefore only costs 385. It has been a flop and only 6156 have been sold. The C2 and C3 are home/office computers and look more professional. The C2 costs 725 and 28345 have been sold. The C3 is almost the same as the C2, but the C3 has a DI DVD player and therefore costs more. It costs 925 and 32379 have been sold. The C4 and C5 are powerful computers with ultra-fast processors that are mainly sold to big companies. The C4 is fitted with the Pl processor, costs 6999, and 674 have been sold. The C5 is fitted with the P2 processor, costs 3999, and 721 have been sold. All prices and sales figures are per package in which they are sold. These are therefore the figures that have to be used. The logistics manager wants to design a logical layout for the warehouse based on an ABC analysis. The managing director has also got involved with the problem of the warehouse design. He has heard about the 80/20 rule. He wants to use this method, but only if it is exactly 80/20, otherwise it won't work according to him. The managing director also wants the calculations to be based on the value of the turnover, in other words the value of the products. "You have to take special care of the expensive articles," he says. The logistics manager does not agree. He says the layout of a warehouse has to be based on an ABC analysis using the sales figures. Question 2 (15+20+5-40 Marks) a) What is an ABC analysis, and how can you use it to design the layout of a warehouse? b) Make two calculations for the ABC analysis: one using the sales figures and the other using the turnover figures. Do they satisfy the 80/20 criterion? (Tip: draw up a list of the figures you need first, think carefully about what these figures mean, what you need to do next, and what figures you already have.) c) The logistics manager and the managing director disagree about whether the ABC analysis should be carried out using the sales figures or the turnover figures. Who is right if you look at the purpose of the analysis?

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Solution a ABC Analybis is a simple way to files folders 8r to optimize olaraiby items ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started