Answered step by step

Verified Expert Solution

Question

1 Approved Answer

linear programming in excel linear programming in excel Problem #1 The Black Betty Division of Block C Enterprises manufactures baseball bats for sales to several

linear programming in excel

linear programming in excel

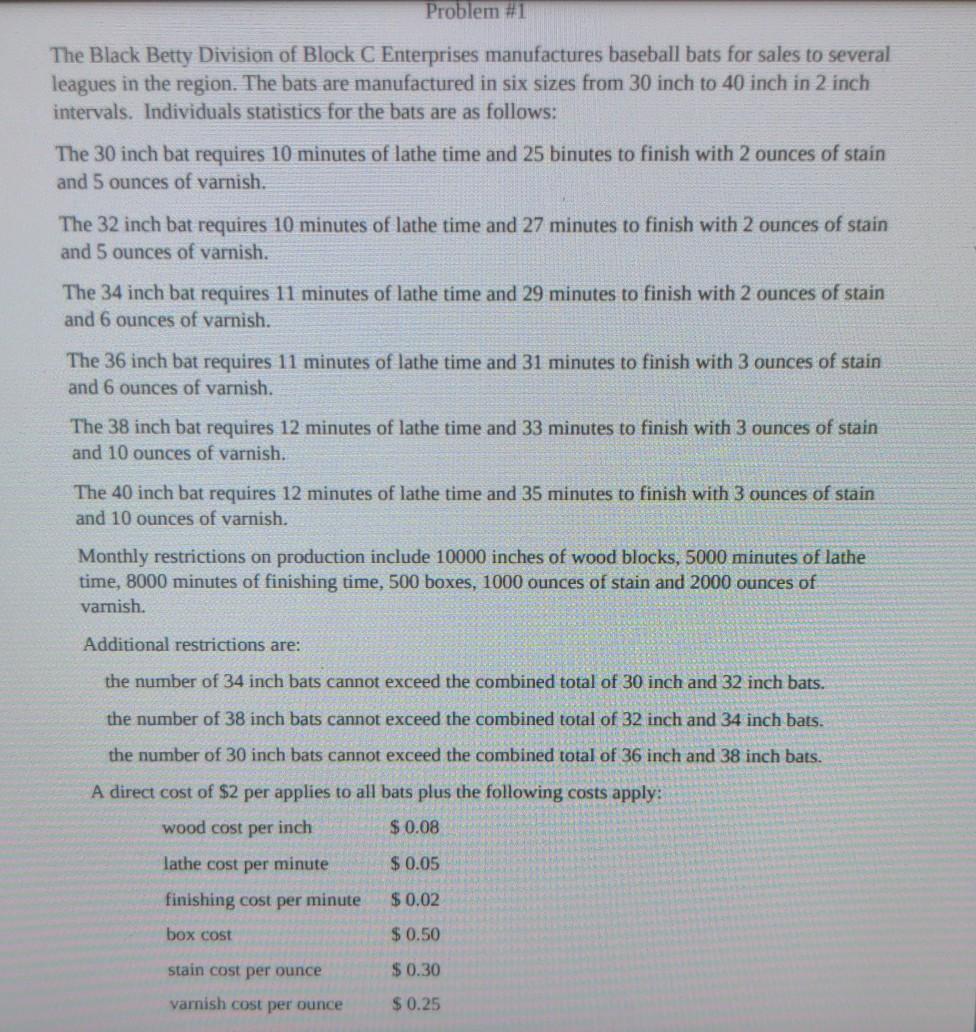

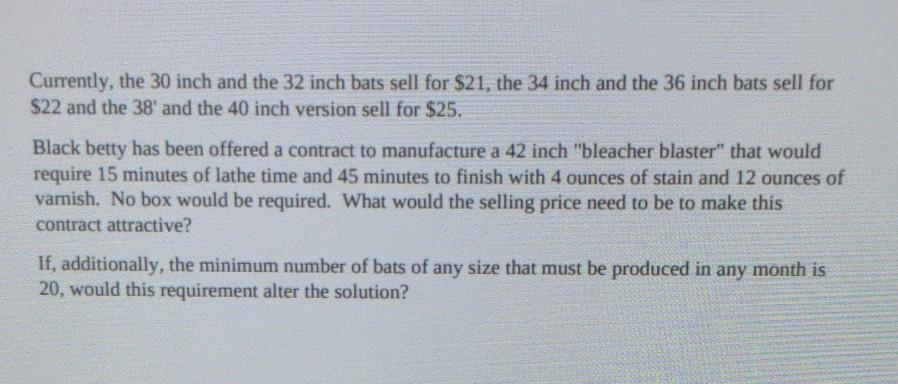

Problem #1 The Black Betty Division of Block C Enterprises manufactures baseball bats for sales to several leagues in the region. The bats are manufactured in six sizes from 30 inch to 40 inch in 2 inch intervals. Individuals statistics for the bats are as follows: The 30 inch bat requires 10 minutes of lathe time and 25 binutes to finish with 2 ounces of stain and 5 ounces of varnish. The 32 inch bat requires 10 minutes of lathe time and 27 minutes to finish with 2 ounces of stain and 5 ounces of varnish. The 34 inch bat requires 11 minutes of lathe time and 29 minutes to finish with 2 ounces of stain and 6 ounces of varnish. The 36 inch bat requires 11 minutes of lathe time and 31 minutes to finish with 3 ounces of stain and 6 ounces of varnish. The 38 inch bat requires 12 minutes of lathe time and 33 minutes to finish with 3 ounces of stain and 10 ounces of varnish. The 40 inch bat requires 12 minutes of lathe time and 35 minutes to finish with 3 ounces of stain and 10 ounces of varnish. Monthly restrictions on production include 10000 inches of wood blocks, 5000 minutes of lathe time, 8000 minutes of finishing time, 500 boxes, 1000 ounces of stain and 2000 ounces of varnish. Additional restrictions are: the number of 34 inch bats cannot exceed the combined total of 30 inch and 32 inch bats. the number of 38 inch bats cannot exceed the combined total of 32 inch and 34 inch bats. the number of 30 inch bats cannot exceed the combined total of 36 inch and 38 inch bats. A direct cost of $2 per applies to all bats plus the following costs apply: wood cost per inch $ 0.08 lathe cost per minute $ 0.05 finishing cost per minute $ 0.02 box cost $ 0.50 stain cost per ounce $ 0.30 varnish cost per ounce $ 0.25 Currently, the 30 inch and the 32 inch bats sell for $21, the 34 inch and the 36 inch bats sell for $22 and the 38' and the 40 inch version sell for $25. Black betty has been offered a contract to manufacture a 42 inch "bleacher blaster" that would require 15 minutes of lathe time and 45 minutes to finish with 4 ounces of stain and 12 ounces of varnish. No box would be required. What would the selling price need to be to make this contract attractive? If, additionally, the minimum number of bats of any size that must be produced in any month is 20, would this requirement alter the solution? Problem #1 The Black Betty Division of Block C Enterprises manufactures baseball bats for sales to several leagues in the region. The bats are manufactured in six sizes from 30 inch to 40 inch in 2 inch intervals. Individuals statistics for the bats are as follows: The 30 inch bat requires 10 minutes of lathe time and 25 binutes to finish with 2 ounces of stain and 5 ounces of varnish. The 32 inch bat requires 10 minutes of lathe time and 27 minutes to finish with 2 ounces of stain and 5 ounces of varnish. The 34 inch bat requires 11 minutes of lathe time and 29 minutes to finish with 2 ounces of stain and 6 ounces of varnish. The 36 inch bat requires 11 minutes of lathe time and 31 minutes to finish with 3 ounces of stain and 6 ounces of varnish. The 38 inch bat requires 12 minutes of lathe time and 33 minutes to finish with 3 ounces of stain and 10 ounces of varnish. The 40 inch bat requires 12 minutes of lathe time and 35 minutes to finish with 3 ounces of stain and 10 ounces of varnish. Monthly restrictions on production include 10000 inches of wood blocks, 5000 minutes of lathe time, 8000 minutes of finishing time, 500 boxes, 1000 ounces of stain and 2000 ounces of varnish. Additional restrictions are: the number of 34 inch bats cannot exceed the combined total of 30 inch and 32 inch bats. the number of 38 inch bats cannot exceed the combined total of 32 inch and 34 inch bats. the number of 30 inch bats cannot exceed the combined total of 36 inch and 38 inch bats. A direct cost of $2 per applies to all bats plus the following costs apply: wood cost per inch $ 0.08 lathe cost per minute $ 0.05 finishing cost per minute $ 0.02 box cost $ 0.50 stain cost per ounce $ 0.30 varnish cost per ounce $ 0.25 Currently, the 30 inch and the 32 inch bats sell for $21, the 34 inch and the 36 inch bats sell for $22 and the 38' and the 40 inch version sell for $25. Black betty has been offered a contract to manufacture a 42 inch "bleacher blaster" that would require 15 minutes of lathe time and 45 minutes to finish with 4 ounces of stain and 12 ounces of varnish. No box would be required. What would the selling price need to be to make this contract attractive? If, additionally, the minimum number of bats of any size that must be produced in any month is 20, would this requirement alter the solutionStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started