Question: Link for the case study-https://www.coursehero.com/file/137208653/Bayer-Case-Studypdf/ A Risk Breakdown Structure and numbering scheme (Graphical format) and A suggested owner for each risk (Case Study is in

Link for the case study-https://www.coursehero.com/file/137208653/Bayer-Case-Studypdf/

A Risk Breakdown Structure and numbering scheme (Graphical format)

and

A suggested owner for each risk

(Case Study is in the photos as well as the link)

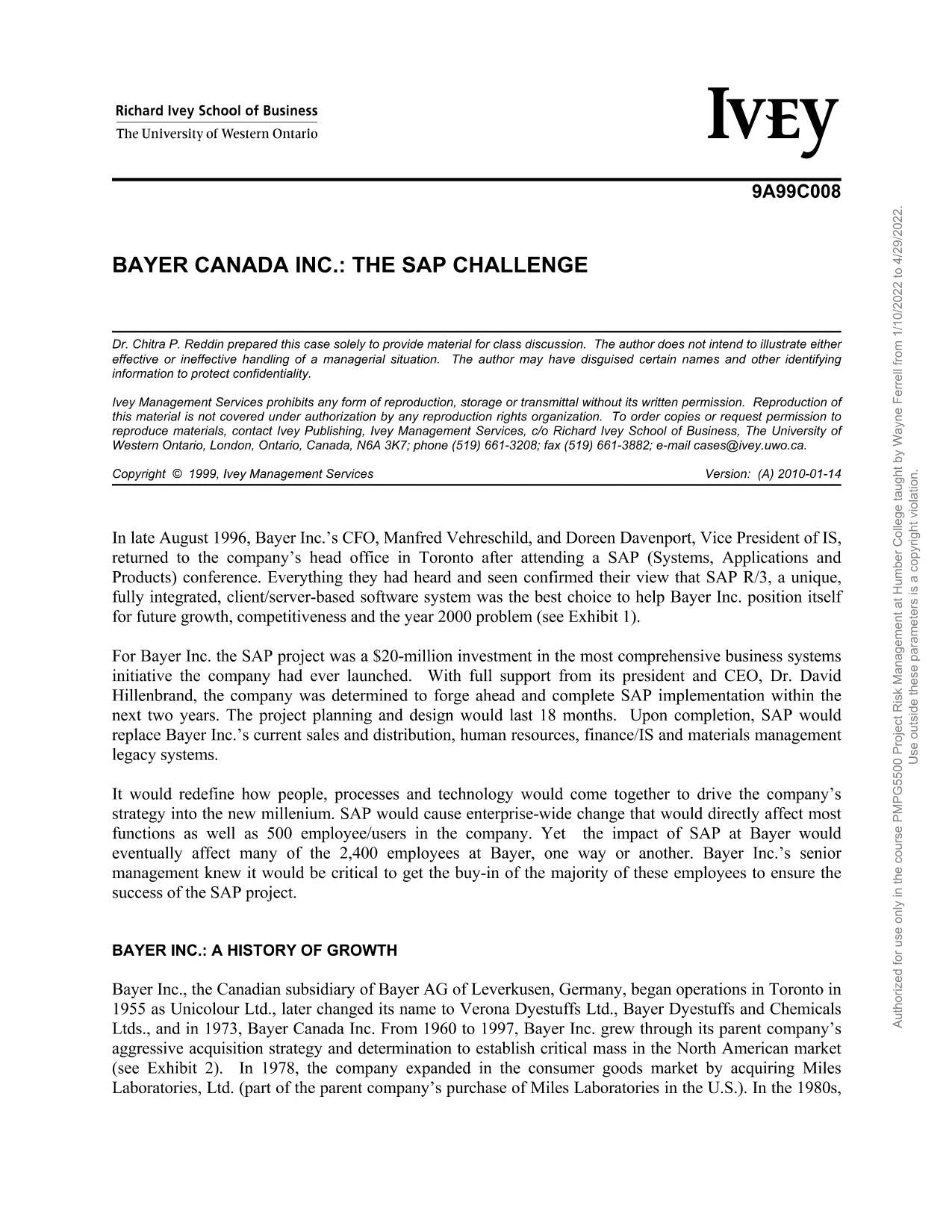

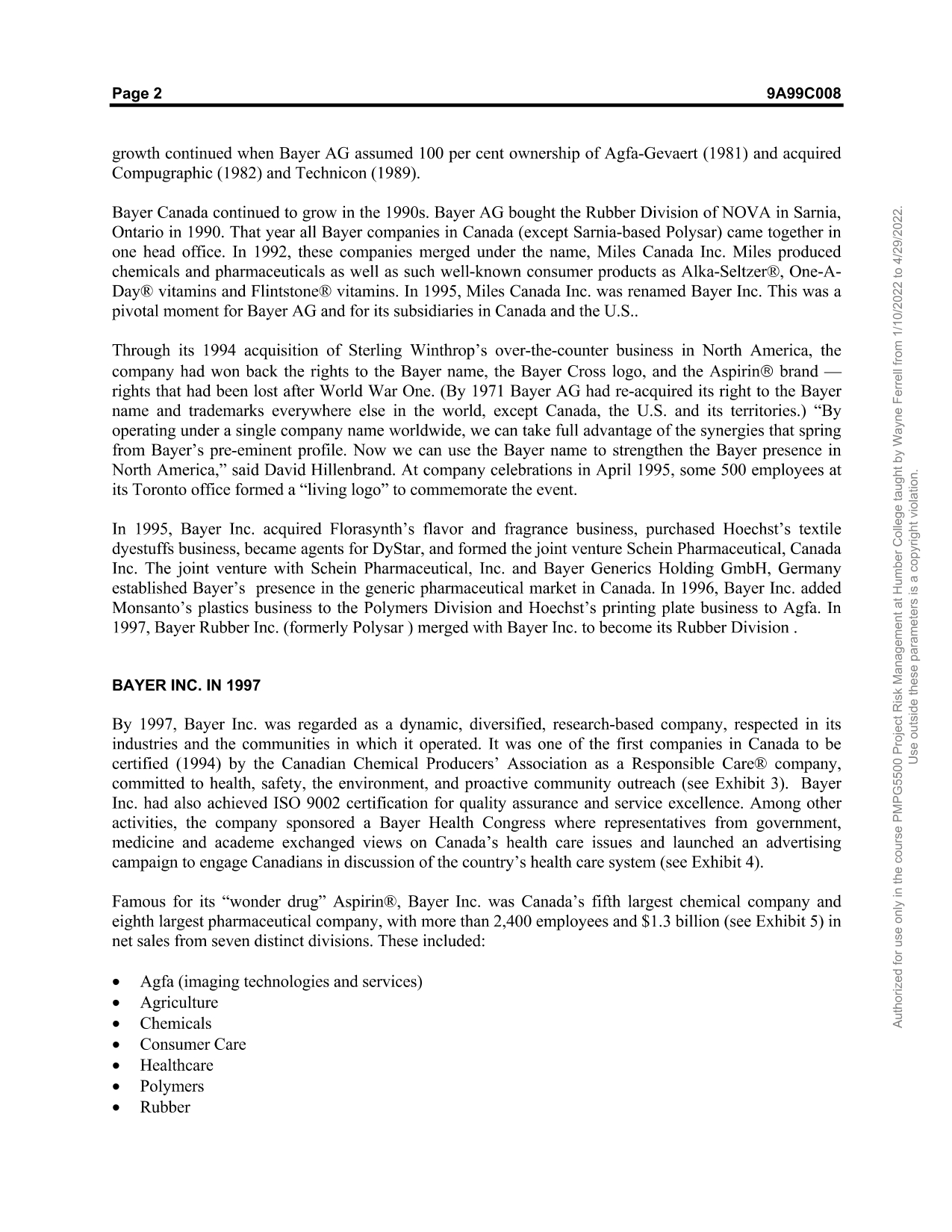

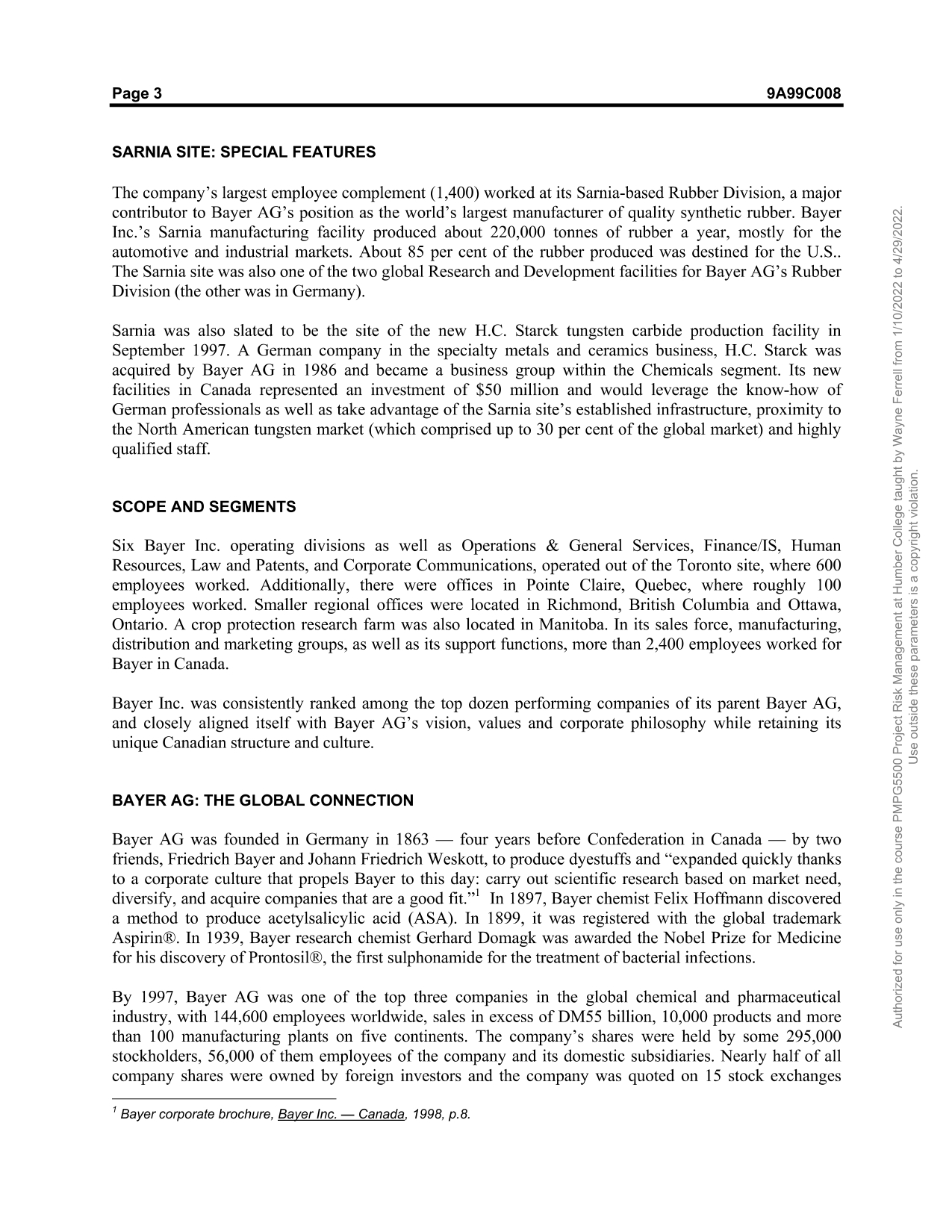

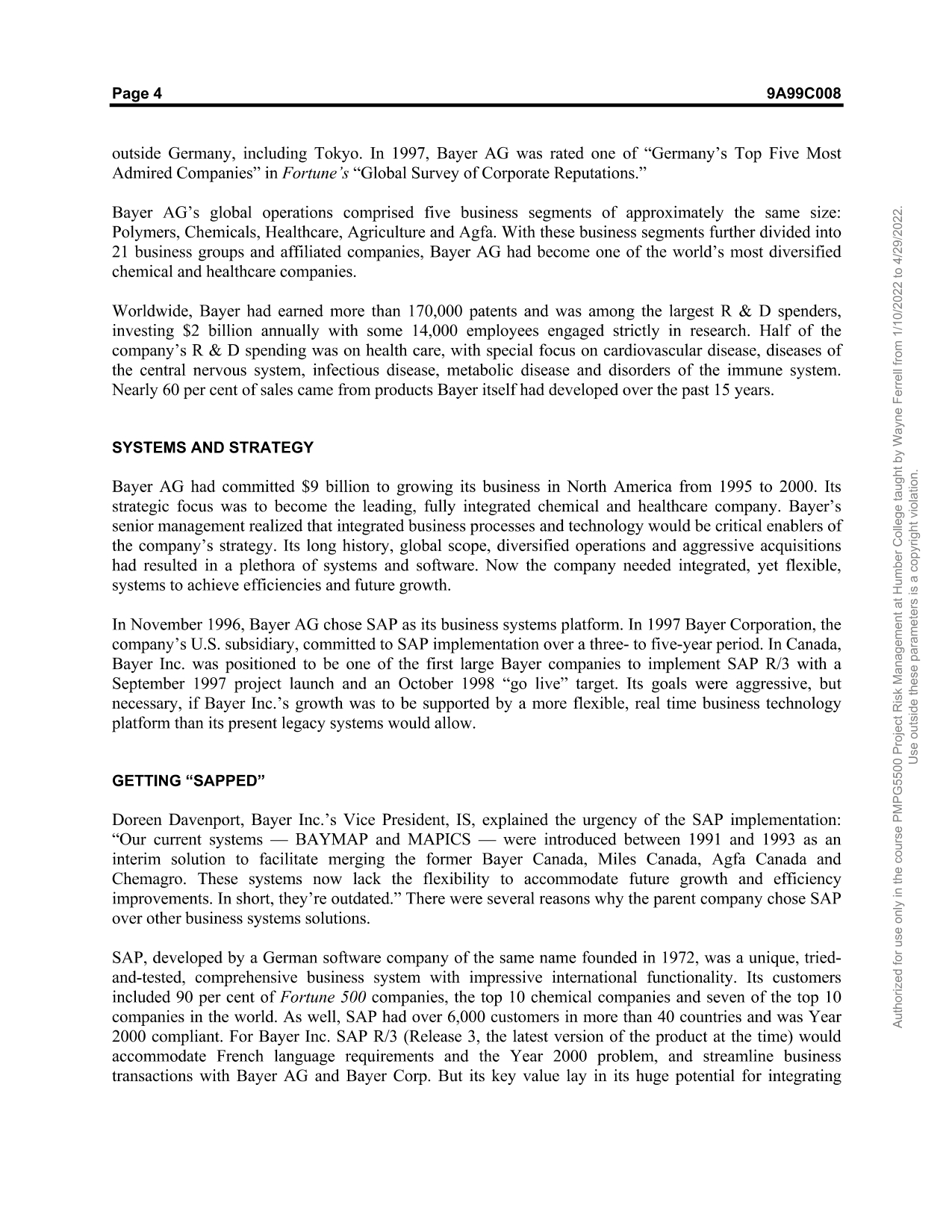

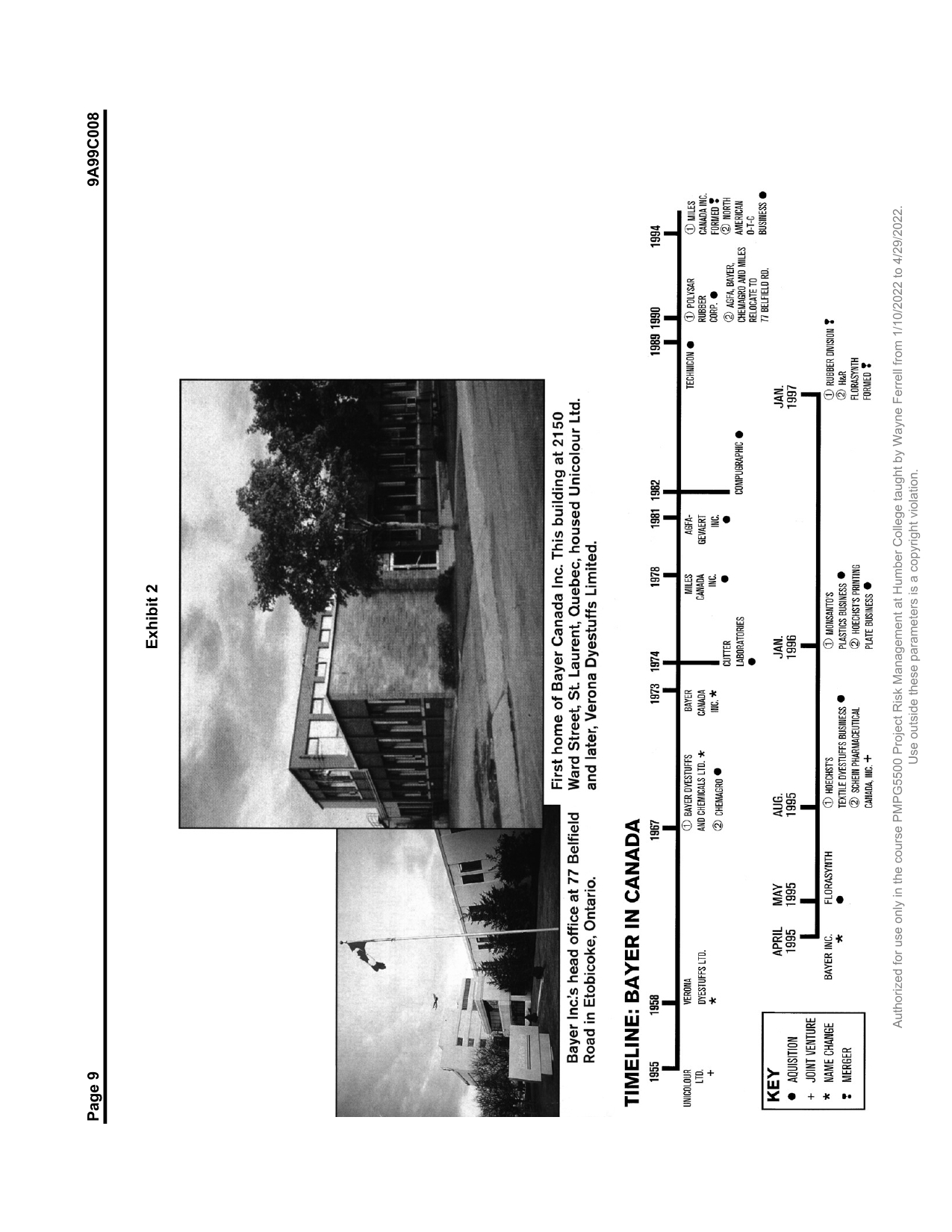

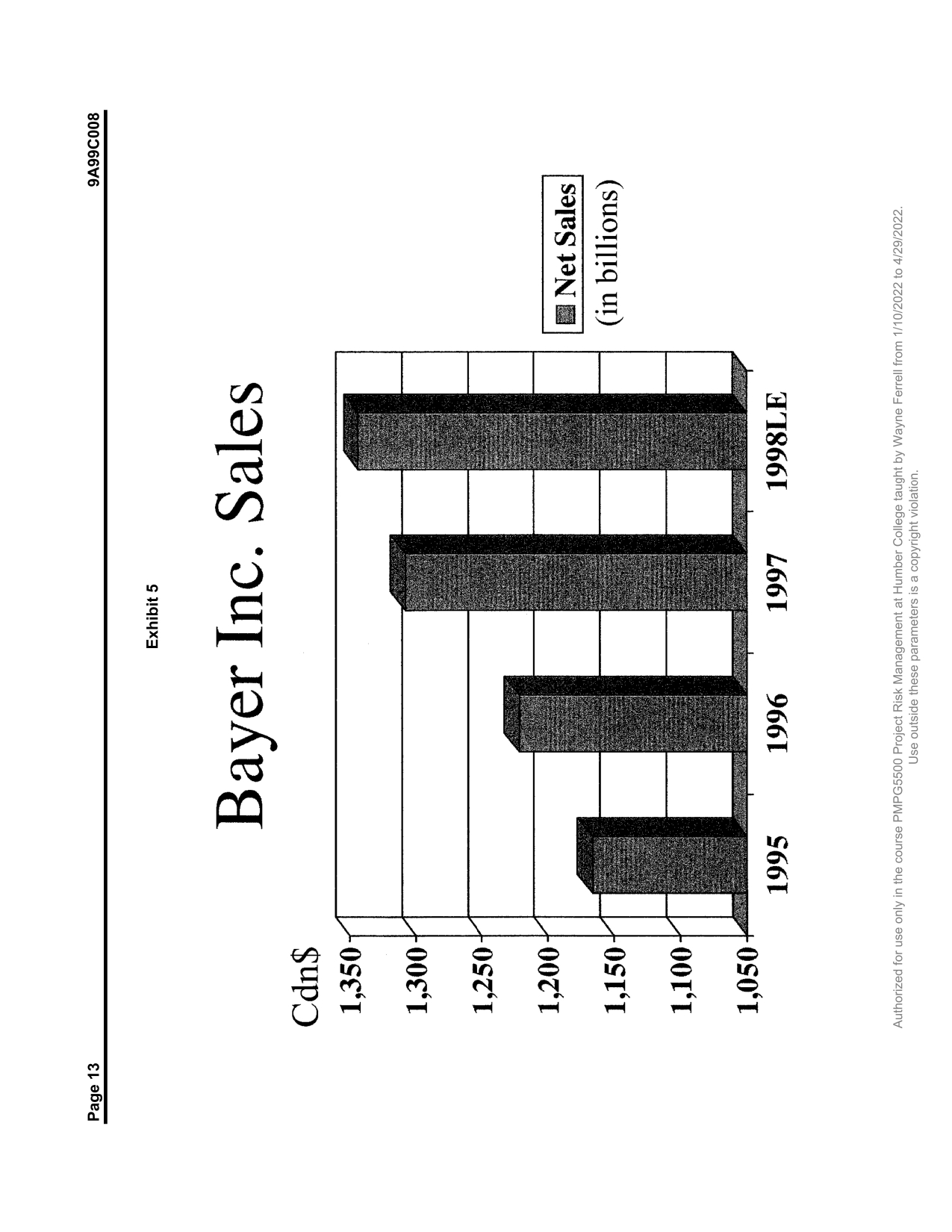

Richard Ivey School of Business The University of Western Ontario IVEY 9A99C008 BAYER CANADA INC.: THE SAP CHALLENGE Dr. Chitra P. Reddin prepared this case solely to provide material for class discussion. The author does not intend to illustrate either effective or ineffective handling of a managerial situation. The author may have disguised certain names and other identifying information to protect confidentiality. Ivey Management Services prohibits any form of reproduction, storage or transmittal without its written permission. Reproduction of this material is not covered under authorization by any reproduction rights organization. To order copies or request permission to reproduce materials, contact Ivey Publishing, Ivey Management Services, clo Richard Ivey School of Business, The University of Western Ontario, London, Ontario, Canada, N6A 3K7; phone (519) 661-3208; fax (519) 661-3882; e-mail cases@ivey.uwo.ca. Copyright @ 1999, Ivey Management Services Version: (A) 2010-01-14 In late August 1996, Bayer Inc.'s CFO, Manfred Vehreschild, and Doreen Davenport, Vice President of IS, returned to the company's head office in Toronto after attending a SAP (Systems, Applications and Products) conference. Everything they had heard and seen confirmed their view that SAP R/3, a unique, fully integrated, client/server-based software system was the best choice to help Bayer Inc. position itself for future growth, competitiveness and the year 2000 problem (see Exhibit 1). Authorized for use only in the course PMPG5500 Project Risk Management at Humber College taught by Wayne Ferrell from 1/10/2022 to 4/29/2022. Use outside these parameters is a copyright violation. For Bayer Inc. the SAP project was a $20-million investment in the most comprehensive business systems initiative the company had ever launched. With full support from its president and CEO, Dr. David Hillenbrand, the company was determined to forge ahead and complete SAP implementation within the next two years. The project planning and design would last 18 months. Upon completion, SAP would replace Bayer Inc.'s current sales and distribution, human resources, finance/IS and materials management legacy systems. It would redefine how people, processes and technology would come together to drive the company's strategy into the new millenium. SAP would cause enterprise-wide change that would directly affect most functions as well as 500 employee/users in the company. Yet the impact of SAP at Bayer would eventually affect many of the 2,400 employees at Bayer, one way or another. Bayer Inc.'s senior management knew it would be critical to get the buy-in of the majority of these employees to ensure the success of the SAP project. BAYER INC.: A HISTORY OF GROWTH Bayer Inc., the Canadian subsidiary of Bayer AG of Leverkusen, Germany, began operations in Toronto in 1955 as Unicolour Lid., later changed its name to Verona Dyestuffs Lid., Bayer Dyestuffs and Chemicals Lids., and in 1973, Bayer Canada Inc. From 1960 to 1997, Bayer Inc. grew through its parent company's aggressive acquisition strategy and determination to establish critical mass in the North American market (see Exhibit 2). In 1978, the company expanded in the consumer goods market by acquiring Miles Laboratories, Ltd. (part of the parent company's purchase of Miles Laboratories in the U.S.). In the 1980s,Page 2 9A99C008 growth continued when Bayer AG assumed 100 per cent ownership of Agfa-Gevaert (1981) and acquired Compugraphic (1982) and Technicon (1989). Bayer Canada continued to grow in the 1990s. Bayer AG bought the Rubber Division of NOVA in Sarnia, Ontario in 1990. That year all Bayer companies in Canada (except Sarnia-based Polysar) came together in one head office. In 1992, these companies merged under the name, Miles Canada Inc. Miles produced chemicals and pharmaceuticals as well as such well-known consumer products as Alka-SeltzerR, One-A- DayR vitamins and FlintstoneR vitamins. In 1995, Miles Canada Inc. was renamed Bayer Inc. This was a pivotal moment for Bayer AG and for its subsidiaries in Canada and the U.S.. Through its 1994 acquisition of Sterling Winthrop's over-the-counter business in North America, the company had won back the rights to the Bayer name, the Bayer Cross logo, and the Aspirin@ brand - rights that had been lost after World War One. (By 1971 Bayer AG had re-acquired its right to the Bayer name and trademarks everywhere else in the world, except Canada, the U.S. and its territories.) "By operating under a single company name worldwide, we can take full advantage of the synergies that spring from Bayer's pre-eminent profile. Now we can use the Bayer name to strengthen the Bayer presence in North America," said David Hillenbrand. At company celebrations in April 1995, some 500 employees at its Toronto office formed a "living logo" to commemorate the event. In 1995, Bayer Inc. acquired Florasynth's flavor and fragrance business, purchased Hoechst's textile dyestuffs business, became agents for DyStar, and formed the joint venture Schein Pharmaceutical, Canada Inc. The joint venture with Schein Pharmaceutical, Inc. and Bayer Generics Holding GmbH, Germany established Bayer's presence in the generic pharmaceutical market in Canada. In 1996, Bayer Inc. added Monsanto's plastics business to the Polymers Division and Hoechst's printing plate business to Agfa. In Authorized for use only in the course PMPG5500 Project Risk Management at Humber College taught by Wayne Ferrell from 1/10/2022 to 4/29/2022. Use outside these parameters is a copyright violation. 1997, Bayer Rubber Inc. (formerly Polysar ) merged with Bayer Inc. to become its Rubber Division . BAYER INC. IN 1997 By 1997, Bayer Inc. was regarded as a dynamic, diversified, research-based company, respected in its industries and the communities in which it operated. It was one of the first companies in Canada to be certified (1994) by the Canadian Chemical Producers' Association as a Responsible Care@ company, committed to health, safety, the environment, and proactive community outreach (see Exhibit 3). Bayer Inc. had also achieved ISO 9002 certification for quality assurance and service excellence. Among other activities, the company sponsored a Bayer Health Congress where representatives from government, medicine and academy exchanged views on Canada's health care issues and launched an advertising campaign to engage Canadians in discussion of the country's health care system (see Exhibit 4). Famous for its "wonder drug" AspirinR, Bayer Inc. was Canada's fifth largest chemical company and eighth largest pharmaceutical company, with more than 2,400 employees and $1.3 billion (see Exhibit 5) in net sales from seven distinct divisions. These included: Agfa (imaging technologies and services) . Agriculture Chemicals . Consumer Care Healthcare . Polymers RubberPage 3 9A99C008 SARNIA SITE: SPECIAL FEATURES The company's largest employee complement (1,400) worked at its Sarnia-based Rubber Division, a major contributor to Bayer AG's position as the world's largest manufacturer of quality synthetic rubber. Bayer Inc.'s Sarnia manufacturing facility produced about 220,000 tonnes of rubber a year, mostly for the automotive and industrial markets. About 85 per cent of the rubber produced was destined for the U.S.. The Sarnia site was also one of the two global Research and Development facilities for Bayer AG's Rubber Division (the other was in Germany). Sarnia was also slated to be the site of the new H.C. Starck tungsten carbide production facility in September 1997. A German company in the specialty metals and ceramics business, H.C. Starck was acquired by Bayer AG in 1986 and became a business group within the Chemicals segment. Its new facilities in Canada represented an investment of $50 million and would leverage the know-how of German professionals as well as take advantage of the Sarnia site's established infrastructure, proximity to the North American tungsten market (which comprised up to 30 per cent of the global market) and highly qualified staff. SCOPE AND SEGMENTS Six Bayer Inc. operating divisions as well as Operations & General Services, Finance/IS, Human Resources, Law and Patents, and Corporate Communications, operated out of the Toronto site, where 600 employees worked. Additionally, there were offices in Pointe Claire, Quebec, where roughly 100 employees worked. Smaller regional offices were located in Richmond, British Columbia and Ottawa, Authorized for use only in the course PMPG5500 Project Risk Management at Humber College taught by Wayne Ferrell from 1/10/2022 to 4/29/2022. Use outside these parameters is a copyright violation. Ontario. A crop protection research farm was also located in Manitoba. In its sales force, manufacturing, distribution and marketing groups, as well as its support functions, more than 2,400 employees worked for Bayer in Canada. Bayer Inc. was consistently ranked among the top dozen performing companies of its parent Bayer AG, and closely aligned itself with Bayer AG's vision, values and corporate philosophy while retaining its unique Canadian structure and culture. BAYER AG: THE GLOBAL CONNECTION Bayer AG was founded in Germany in 1863 - four years before Confederation in Canada - by two friends, Friedrich Bayer and Johann Friedrich Weskott, to produce dyestuffs and "expanded quickly thanks to a corporate culture that propels Bayer to this day: carry out scientific research based on market need, diversify, and acquire companies that are a good fit." In 1897, Bayer chemist Felix Hoffmann discovered a method to produce acetylsalicylic acid (ASA). In 1899, it was registered with the global trademark AspirinR. In 1939, Bayer research chemist Gerhard Domagk was awarded the Nobel Prize for Medicine for his discovery of Prontosil@, the first sulphonamide for the treatment of bacterial infections. By 1997, Bayer AG was one of the top three companies in the global chemical and pharmaceutical industry, with 144,600 employees worldwide, sales in excess of DM55 billion, 10,000 products and more than 100 manufacturing plants on five continents. The company's shares were held by some 295,000 stockholders, 56,000 of them employees of the company and its domestic subsidiaries. Nearly half of all company shares were owned by foreign investors and the company was quoted on 15 stock exchanges Bayer corporate brochure, Bayer Inc. - Canada, 1998, p.8.Page 4 9A99C008 outside Germany, including Tokyo. In 1997, Bayer AG was rated one of "Germany's Top Five Most Admired Companies" in Fortune's "Global Survey of Corporate Reputations." Bayer AG's global operations comprised five business segments of approximately the same size: Polymers, Chemicals, Healthcare, Agriculture and Agfa. With these business segments further divided into 21 business groups and affiliated companies, Bayer AG had become one of the world's most diversified chemical and healthcare companies. Worldwide, Bayer had earned more than 170,000 patents and was among the largest R & D spenders, investing $2 billion annually with some 14,000 employees engaged strictly in research. Half of the company's R & D spending was on health care, with special focus on cardiovascular disease, diseases of the central nervous system, infectious disease, metabolic disease and disorders of the immune system. Nearly 60 per cent of sales came from products Bayer itself had developed over the past 15 years. SYSTEMS AND STRATEGY Bayer AG had committed $9 billion to growing its business in North America from 1995 to 2000. Its strategic focus was to become the leading, fully integrated chemical and healthcare company. Bayer's senior management realized that integrated business processes and technology would be critical enablers of the company's strategy. Its long history, global scope, diversified operations and aggressive acquisitions had resulted in a plethora of systems and software. Now the company needed integrated, yet flexible, systems to achieve efficiencies and future growth. Authorized for use only in the course PMPG5500 Project Risk Management at Humber College taught by Wayne Ferrell from 1/10/2022 to 4/29/2022. Use outside these parameters is a copyright violation. In November 1996, Bayer AG chose SAP as its business systems platform. In 1997 Bayer Corporation, the company's U.S. subsidiary, committed to SAP implementation over a three- to five-year period. In Canada, Bayer Inc. was positioned to be one of the first large Bayer companies to implement SAP R/3 with a September 1997 project launch and an October 1998 "go live" target. Its goals were aggressive, but necessary, if Bayer Inc.'s growth was to be supported by a more flexible, real time business technology platform than its present legacy systems would allow. GETTING "SAPPED" Doreen Davenport, Bayer Inc.'s Vice President, IS, explained the urgency of the SAP implementation: "Our current systems - BAYMAP and MAPICS - were introduced between 1991 and 1993 as an interim solution to facilitate merging the former Bayer Canada, Miles Canada, Agfa Canada and Chemagro. These systems now lack the flexibility to accommodate future growth and efficiency improvements. In short, they're outdated." There were several reasons why the parent company chose SAP over other business systems solutions. SAP, developed by a German software company of the same name founded in 1972, was a unique, tried- and-tested, comprehensive business system with impressive international functionality. Its customers included 90 per cent of Fortune 500 companies, the top 10 chemical companies and seven of the top 10 companies in the world. As well, SAP had over 6,000 customers in more than 40 countries and was Year 2000 compliant. For Bayer Inc. SAP R/3 (Release 3, the latest version of the product at the time) would accommodate French language requirements and the Year 2000 problem, and streamline business transactions with Bayer AG and Bayer Corp. But its key value lay in its huge potential for integratingPage 5 9A990008 business processes, data and systems across the enterprise, and accelerating Bayer lnc.'s strategy and growth. As observed by one SAP consultant: \"SAP stands alone in providing real time updating in an integrated fashion throughout the entire system. The advantage this offers is breathtaking. A sales order comes in and its entry will update (depending upon configuration variable) the materials management system and-"or purchasing, and/or production planning and cash flow. . . . If SAP hears a pin drop on a shop floor, the sound will be heard in assets management." But SAP also often posed several signicant challenges to companies who chose to implement. Among these were the lengthy and detailed business process analysis and redesign, complexity of configuration, uniqueness of SAP's system architecture, programming language and functionality, high tumover (from 30 to 70 per cent) of SAP implementation team members, and the significant cost, training and implementation time required. By far the biggest challenge was the tsunami of organizational change that resulted from a SAP implementation. SAP was a business-driven, rather than a systems-driven initiative. Typically, SAP cut across existing functional boundaries and company hierarchies. lt redistributed power and decision- making, reshaping or creating new accountabilities and eliminating old ones. Among industry media and some companies and consultants who had already implemented SAP, the acronym had begun to acquire wry, alternative meanings: Submit And Pray; Saeking Antique Personnel; Shoot A Programmer, to name a few. Aware of the challenges, by March l997 Bayer Inc. had in place an lS-member SAP Steering Committee, chaired by David Hillcnbrand. The committee comprised the head of each operating division and support group, key personnel across the company, and several external SAP and project consultants working with Bayer Inc. on the project. Soon thereafter, the SAP Core Team called their project: \"Genesis: A blew Beginning\". This core team of about 30 people was comprised mostly of high-performance employees from throughout Bayer Inc. who were seconded to the project. SAP Project Leader Paul Singleton explained how the core team was selected: \"We looked for employees that are very receptive to change, and can objectively represent the interests of all the divisions and support groups. This highly capable team will essentially design a new way of doing business that will lead Bayer into the next century." The Genesis Core Team's mandate was to examine and help redesign the company's larger business processes. As well, a Change Integration Team (CIT) was formed consisting of Bayer Inc. managers across all operating divisions and support groups, whose role would be to facilitate communications about SAP and help identify end-user requirements in their area of the company. All of Bayer Inc's support groups and six of its seven operating divisions were involved in the SAP project. The exception, the Rubber Division and its Sarnia Site neighbour, H.C. Starck, aligned their SAP timing with that of Bayer Corporation in the United States. To understand this fully, one needed to understand Bayer's matrixed structure. Rubber and H.C. Starck were closely linked to regional business operations in the U.S. For this reason, a decision was made early on for Sarnia Site's SAP timelines to coincide with those of the U.S.. However, of the 1,240 people located in Sarnia, 60 employees, mainly human resources and payroll staff, were on course to ' go live' with the rest of Bayer in Canada. This was because HR. and payroll were support functions that reported to Bayer Inc. in Toronto. " L"I-..|| "to-'1 170-00? \"Jr's-y I 'r: Ligjlil by |0"I. '9' EL ..'-_> I) f:- r". LL .1. ~. : I '_l e tun :-' Anilug-r .'Lt_l ir_i- L'DL' r'_:'|l:, Page 6 9A990008 THE COMMUNICATIONS CHALLENGE A member of the SAP steering committee from the start, Karen Schwartz, Director, Corporate Communications, knew that SAP implementations at other companies frequently failed because of a lack of upfront and sustained understanding of the nature, impact and benets of SAP among employees. Bayer lne.'s $20-million investment and the potential benets and opportunities ofits SAP initiative could disappear and employee morale and productivity plummet, if the company failed to address a whole host of issues and concerns. One of the key concerns would likely be job security. The 1990s had witnessed an unprecedented global wave of corporate restructuring and reengineering, resulting almost inevitably in job losses, frequently of staggering proportions. Any business systems project of signicant size and scope would likely have all the attraction of a root canal operation. At Bayer Inc. the SAP implementation would reinvent business processes and worktlows and could trigger high employee anxiety. As a consultant observed of other SAP implementations: \"One worried employee is a case for people skills. A thousand worried employees is a massive loss of production.\" For Bayer lnc._. the primary focus of its SAP project was strategic positioning, not cutting jobs. But there was no guarantee that some jobs would not be eliminated. Driven by its corporate vision and values, the company was committed to redeploying and re-lraining employees, whoscjobs might become redundant as a result of the project. Realistically, this would not always be possible. Another key issue was managing employee expectations. Bayer lne. was a diversied company and SAP was a complex process that took time to implement and to get measurable results. Employees would likely compare its functionality with the systems and processes they were used to, and expect SAP to deliver quantum improvements and quick wins. There was bound to be some skepticism as well as unrealistically high expectations. SAP would also require highly intensive training and would not be easy to use right from the start. The fact that the company did not propose to run its old systems and SAP in tandem during a transition phase would add to employee stress and resistance. Fear of the unknown was the critical factor. Bayer lnc.'s SAP implementation could not be anticipated or measured by any of its previous systems projects. The widespread impact and unique characteristics of SAP Rf3 made this impossible. Bayer Inc. was prepared to invest heavily in training, not only in the SAP platform and new business process, but also other types of training that would set employees up for success in new roles. To ease the transition from new systems to old, it planned to set up an online, risk-free \"sandbox" where employees could get used to the look, feel, functionality and features of SAP, without having an impact on business data and processes, before SAP went live. The 18-month to two-year time-frame was in itself a challenge. Schwartz realized her communications strategy for SAP would require clear, continuous, consistent and credible communications, early and throughout the SAP project, to ensure its success. Open communication was a core Bayer Inc. value and Schwartz knew she had the support of Bayer Inc's senior management team and the resources to plan and execute an effective communications strategy. Over the next two years she would work closely with David Hillenbrand. the SAP Steering Committee, the Genesis Core Project Team and the CIT on communications initiatives to facilitate the success of the company's SAP project. She began to set some priorities and think about the immediate and long-term components of her plan. " c'i..|| "to-'11 '_\\ .H _"-J '_.-it' In C: LL L'i. _n ;_:iI|-_-r i i _l L' L[_:._.l':= ':.z_! .1! L lt AJliii .-i . i_s:_: Page 7 9A99C008 Exhibit 1 SAP Systems, Applications and Products in Data Processing QuickFacts ...about SAP-the company and the software SAP is a German software company founded in 1972 SAP stands for Systems, Applications and Products in data processing Customers include 90% of Fortune 500 companies The top 10 chemical companies in the world use SAP Of the top 10 pharmaceutical companies in the world, seven use SAP Of the top 10 companies in the world with the highest return on assets, seven use SAP O SAP has over 30% market share in its market type SAP has over 6,000 customers in more than 40 countries SAP invests 20% of its revenues into research and development O SAP supports multiple languages and multiple currencies Authorized for use only in the course PMPG5500 Project Risk Management at Humber College taught by Wayne Ferrell from 1/10/2022 to 4/29/2022. Use outside these parameters is a copyright violation. J SAP supports country-specific import/export, tax and legal requirements J SAP supports country-specific holiday calendars J SAP platform partners include AT&T, Compaq, Sun, IBM and Hewlett Packard " SAP technology partners include Microsoft, IBM, Apple, Oracle and Intel O SAP R/3 can be configured for most industries including chemicals, pharmaceuticals, automotive and consumer products J SAP R/3 integrates business processes across the entire enterprise O SAP operates in real time-that is, once information is entered into SAP it is immediately available O SAP is year 2000 compliant O SAP has over 1,000 business process models O SAP's web site is www.sap.com Watch for frequently asked questions and answers about SAP in the next issue September 1997) of Cross Communicator. Bayer PERPage 3 9A990008 Exhibit 1 (continued) benchmark to measure a company's \"as-is\" perfor mance against that of similar companies or against best practices or as a baseline measure against iture improvement best practices collection of business solutions that have been developed within particular departments, companies or industries that are copied by other organizations because they are considered best of class BPR business process reengineering; approach used to implement fundamental change in the way daily operations are performed in an organization. When undertaking BPR, the company reexamines what is important to the customer and then utilizes powerful technologies and redenes existing relationships to achieve maximum performance, sustain a competitive advantage and meet the needs ofits customers. business process a combination of related groups of business activities (the groups being sub-processes) performed within and across functions that produces an outcome that serves part of the overall business purpose examples: product development, order management, customer service, nancial reporting commonality potential to share processes, data hierarchy or code structures across functions, divisions or business groups enterprise-wide pertains to entire company; usually used to describe systems, processes or teams that are common to or potentially common to the entire company function - area of company that performs a specic set of related business processes examples: Research & Development, Production, Marketing/Sales, Accomting hierarchy planned organization of and access to informationso that access is granted as appropriate for each business, function or job levelwith the purpose of maintaining data integrity while meeting global reporting requirements and supporting efcient operations at the business group, regional. country and local levels integrity - accuracy, quality, validity and safety of data from unauthorized access or use legacy systems existing hardware and software that may need to be altered or replaced over time to meet the current business requirements of an organization; for example, the legacy systems in many organizations are not equipped to meet the year 2000 problem master data collection of data stored electronicallysuch as vendor, customer and supplier codesithat is pooled from all businesses or functional areas and harmonized to create a. common coding and information structure module a set of business processes as dened by SAP that is within the Scope of BPR/SAP implementation. examples: Production Plaiuiing, Sales & Distribution, Plant Maintenance, Financial Accounting process Visioning planning phase to dene future business processesespecically the major activities, people, infrastructure and technology needed to achieve the new business processeswith the resulting vision guiding the organization as it congures the new technology and transforms to its future state SAP client/server business software package (SAP RB) that can be congured to meet the business requirements of almost all businesses and functional areas of a company. SAP enables different areas of a company to operate on one integrated infrastructure, promoting more efficient business operations; also is the name of the company that develops SAP software and is an acronym for systems, applications and products in data processing. sub-process group of business activities that accomplishes an essential part of a business process example: \"manage delivery schedule\" is a sub-process within the order management process Page 9 9A99C008 Exhibit 2 First home of Bayer Canada Inc. This building at 2150 Bayer Inc's head office at 77 Belfield Ward Street, St. Laurent, Quebec, housed Unicolour Ltd. Road in Etobicoke, Ontario. and later, Verona Dyestuffs Limited. TIMELINE: BAYER IN CANADA 1955 1958 1967 1973 1974 1978 1981 1982 1989 1990 1994 UNICOLOUR ERONA 1 BAYER DYESTUFFS BAYER MILES AGFA- TECHNICON . D POLYSAR MILES LTD. DYESTUFFS LTD. AND CHEMICALS LTD. * CANADA CANADA + GEVAERT RUBBER CANADA INC 2) CHEMAGRO INC. * INC. INC. CORP. FORMED CUTTER 2 AGFA, BAYER, 2) NORTH LABORATORIES COMPUGRAPHIC . CHEMAGRO AND MILES AMERICAN RELOCATE TO O-T-C KEY 77 BELFIELD R BUSINESS APRIL MAY AUG. JAN. JAN. . AQUISITION 1995 1995 1995 1996 1997 JOINT VENTURE * NAME CHANGE BAYER INC. LORASYNTH 1 HOECHST'S 1 MONSANTO'S 1 RUBBER DIVISION MERGER TEXTILE DYESTUFFS BUSINESS . PLASTICS BUSINESS . 2) H&R (2) SCHEIN PHARMACEUTICAL (2) HOECHST'S PRINTING FLORASYNTH CANADA, INC. + PLATE BUSINESS . FORMED Authorized for use only in the course PMPG5500 Project Risk Management at Humber College taught by Wayne Ferrell from 1/10/2022 to 4/29/2022. Use outside these parameters is a copyright violation.Page 10 MEET OUR RESPONSIBLE CARE MANAGERS: "Protection of the environment and the safe operation of the Sarnia plant are fundamen tal values for us. CAER addresses how we communicate these values to our neighbours and receive feedback from them. We value this open and honest communication facilitated by Responsible Care." Gunter Hilken, Senior Vice President and Site Manager; photo: Wayne Windjack Community Awareness and Emergency Response (CAER) Code At Bayer Inc., Sarnia Site, effluent water samples are taken on a routine basis and analyzed by our laboratory. Here Steve Mullen is collecting a sample from the "One of the most important aspects of our BIOX effluent. All process streams from the site are R & D activities is to develop new and/or treated at our Biological Oxidation ('BIOX') Plant to improved products and processes that, over ensure clean water is released back to the St. Clair their entire life cycle, have minimal impact River. on health, environment and safety." Heinz H. Greve, Vice President, Technology; photo: Grant Hill Research and Development Code Bayer Inc. "We will minimize the impact of our Sarnia Site Exhibit 3 operations on the environment, the community, our customers and our AND employees." Jim Raines, Director, BR/NBR; Manufacturing Code Responsible Care "Transportation Community Awareness and Emergency Response ('Transcaer') is a A Total Commitment "partnership" among manufacturers, carrier RESPONSIBLE and community first responders. We will @ Trademark of the Canadian Chemical Producers' Association strive to address community concerns about - used under license by Bayer Inc. the transportation of hazardous materials through planning, training and CARE co-operation." Ken Dunn, Director, Logistics Transportation/Distribution Code Bayer Inc. PLEDGES ITS COMMITMENT "We are committed to managing our TO THE GUIDING PRINCIPLES waste in a way that protects people and Bayer the environment." OF RESPONSIBLE CARE Archie Kerr, Director, Health, Environment & Safety; Hazardous Waste Management Code 9A99C008 Authorized for use only in the course PMPG5500 Project Risk Management at Humber College taught by Wayne Ferrell from 1/10/2022 to 4/29/2022. Use outside these parameters is a copyright violation.WHO ARE WE? WHAT IS RESPONSIBLE CARE? HOW DOES BAYER INC., SARNIA SITE Bayer Inc. in Sarnia Ontario, has corporate offices in PRACTICE RESPONSIBLE CARE? Page 11 Toronto. This Canadian company is a subsidiary of Bayer AG (Germany), an international chemical All operations are governed by the CCPA health care, and imaging technology company. Responsible Care Codes of Practice: The Sarnia Site has both manufacturing and R&D/ Archie Kerr, Director, technology facilities for quality synthetic rubber. It is Health, Environment & Safety Community Awareness and Emergency Response (CAER) a major supplier of synthetic rubber to both domestic and international markets. As well, it is home to H.C. Research and Development Starck, a Bayer subsidiary and specialty metal company. V Manufacturing "As a Responsible Care Responsible Care is a set of guiding principles sub company, one of our goals is to scribed to by member companies of the Canadian Transportation (Transcaer) "go the extra mile". I am Chemical Producers' Association (CCPA). These pleased, as President and Chief guiding principles express to our employees, the pub- Distribution Executive Officer of Bayer Inc., lic and governments that we are a responsible indus- to report that we participate in try. As a member, we are committed to: V Hazardous Waste Management many initiatives that underscore the importance we place on . Ensuring that our operations do not pose an We pledge to manage our business according to the safety and the environment: air unacceptable risk to employees, customers, the principles of Responsible Care. emission reduction programs, community or the environment; David Hillenbrand environmental improvements President and CEO Bayer Inc. employee awareness training . Providing relevant information on the potential and community outreach. By hazards of our products and operations to We accomplish this by: going the extra mile, Bayer Inc. employees benefit customers and the general public; Exhibit 3 (continued) from a better, cleaner, safer workplace. I thank them *Training our professional staff in the areas of the for their efforts in making Responsible Care an inte- . Making Responsible Care an early and integral Responsible Care Codes of Practice; gral part of our business, and ask for their continued part of the planning process leading to new support of our programs and initiatives." products, processes or plants; *Striving to protect the environment through the constant examination of our processes and WHERE CAN YOU FIND OUR PRODUCTS? . Increasing the emphasis on the understanding of products; Rubber is a necessity for the quality and style of life existing products and their uses; ensuring that a in today's society. Synthetic rubber is widely used in: high level of understanding of new products and *Ensuring minimal environmental impact through Health Care: stethoscopes, oxygen hoses, breathing their potential hazards is achieved prior to and constant control and improvement of our process- throughout commercial development; es and products. apparatus, osteopathic bindings and equipment Travel: truck, automobile and bicycle tires, extensive . Complying with all legal requirements which affect our operations and products; Bayer Inc., Sarnia Site strives to be a corporate leader use in the automotive industry. in its commitment to Responsible Care. Industry: conveyor belts, hoses, protective clothing. . Being responsive and sensitive to legitimate Responsible Care is one aspect of our total integrated Business: office furniture, non-slip flooring. community concerns; health, environmental and safety program. Communications: cables, computers, telephones. . Working actively with, and assisting governments and selected organizations, to foster and encourage Homes: dishwashers, refrigerators, washing equitable and attainable standards. machines, dryers, faucet O rings, flooring, paints. Tungsten carbide is a powder used mainly in the 9A99C008 hardmetal industry for the manufacture of a wide FOR FURTHER INFORMATION range of metal-cutting tools. CALL DIRECT (519) 337-8251, Ext. 7810 Authorized for use only in the course PMPG5500 Project Risk Management at Humber College taught by Wayne Ferrell from 1/10/2022 to 4/29/2022. Use outside these parameters is a copyright violation.Page 12 9A99C008 Exhibit 4 Authorized for use only in the course PMPG5500 Project Risk Management at Humber College taught by Wayne Ferrell from 1/10/2022 to 4/29/2022. Use outside these parameters is a copyright violation. Good communication between health care professionals and patients is proven to improve the patient's well-being - not just emotionally, but also in terms of physical improvements like blood pressure and pain control. At our Institute for Health Care Communication, doctors, pharmacists and other health care professionals gain new insight into how they communicate with patients and how to enhance the process. More than 2,000 Canadian practitioners have already benefited. For more information about this non-profit organization, please write to us at Bayer Inc., clo Viewpoints, 77 Belfield Road, Etobicoke, Ontario, MOW 106, or e-mail us at healthcare. viewpoint.b@bayer.com BayerPage 13 9A99C008 Exhibit 5 Bayer Inc. Sales Cdn$ 1,350 1,300 1,250 1,200 Net Sales 1,150 (in billions) 1,100 1,050 1995 1996 1997 1998LE Authorized for use only in the course PMPG5500 Project Risk Management at Humber College taught by Wayne Ferrell from 1/10/2022 to 4/29/2022. Use outside these parameters is a copyright violation

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts