Answered step by step

Verified Expert Solution

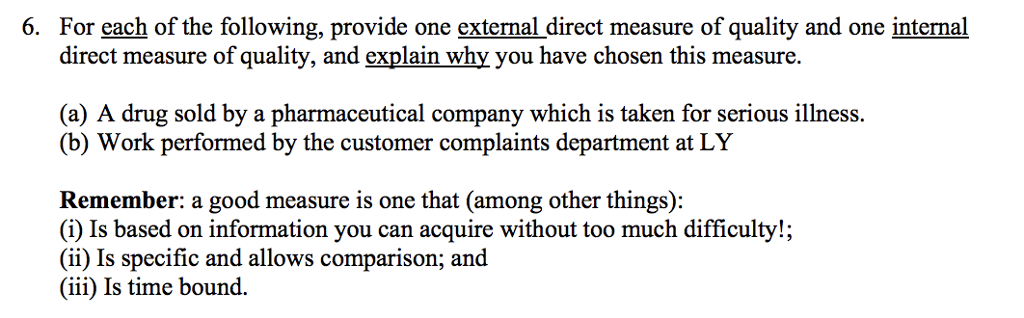

Question

1 Approved Answer

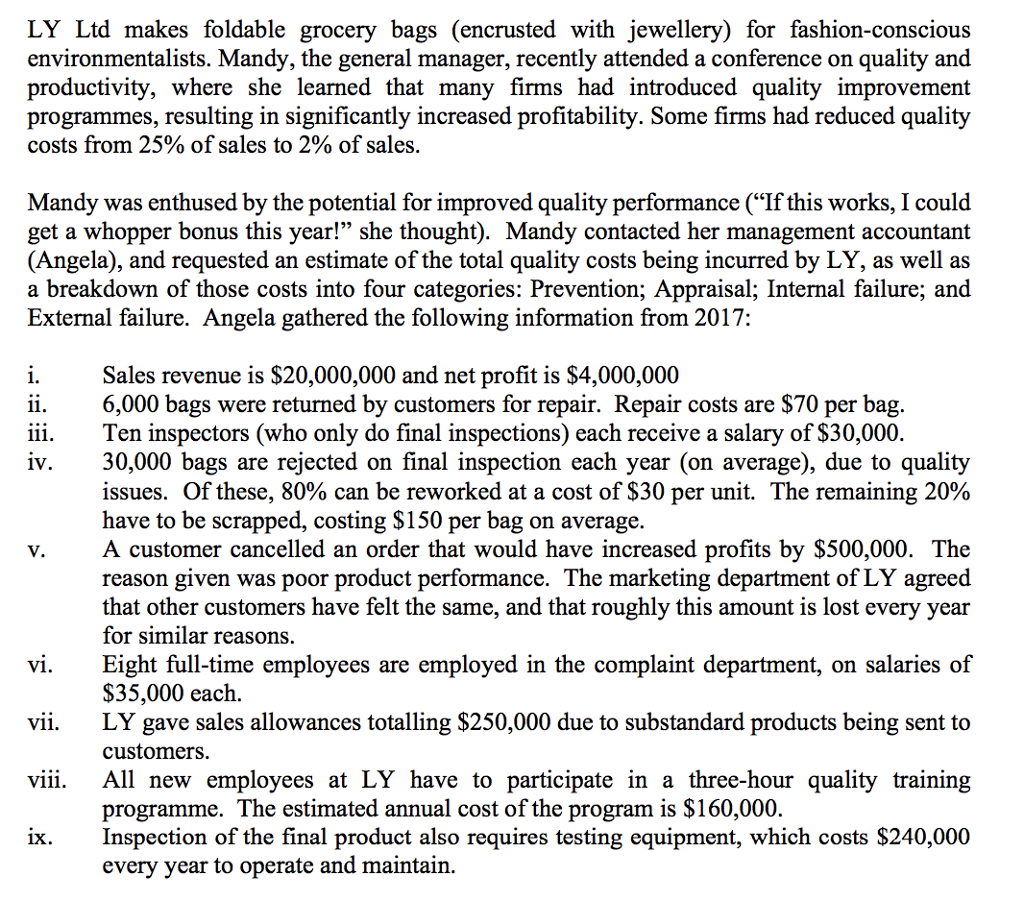

LY Ltd makes foldable grocery bags (encrusted with jewellery) for fashion-conscious environmentalists. Mandy, the general manager, recently attended a conference on quality and productivity, where

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started