Question

M5 Problem Set - Quality Through Process Control A process filling small bottles with baby formula has a target of 3 ounces 0.10 ounces. In

M5 Problem Set - Quality Through Process Control

A process filling small bottles with baby formula has a target of 3 ounces 0.10 ounces. In other words, a bottle must contain between 2.9 and 3.1 ounces of baby formula.As part of a periodic process capability study, two hundred bottles from the process were sampled. The results showed the average amount of formula placed in the bottles to be 3.042 ounces with a standard deviation of 0.033 ounces.

a. Would you consider this process capable of meeting the required specifications?Answer by calculating an appropriate measure of capability.

b.Assuming that the quantity of formula in a bottle is normally distributed, out of a batch of a million bottles how many do you think would be unacceptable - i.e., outside the specification limits?

c.Currently the process is not centered.If the process is adjusted so that it becomes centered, what is the impact on the process capability measure that you calculated in (a)?

d.Assume that the process is centered.What should the process standard deviation be in order for the process to be considered Six-Sigma compliant (i.e., have Cp or Cpk of 2.0)?

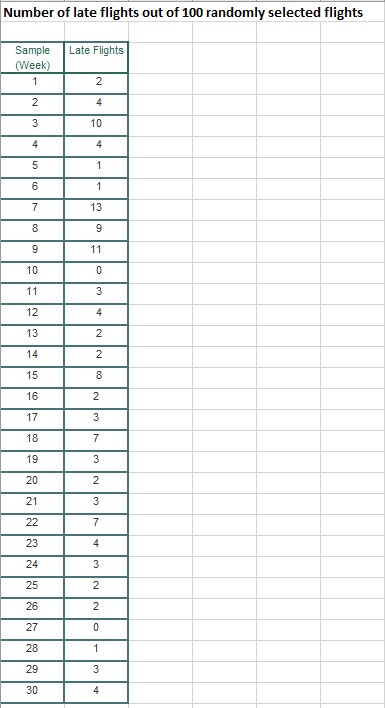

Table below: Please include all calculations/formulas in excel

?

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started