Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Make sure you get it correct! thank you Problem 3. (Chapter 5 Project Management) Table below contains information about an environmental clean-up project. Shorten the

Make sure you get it correct! thank you

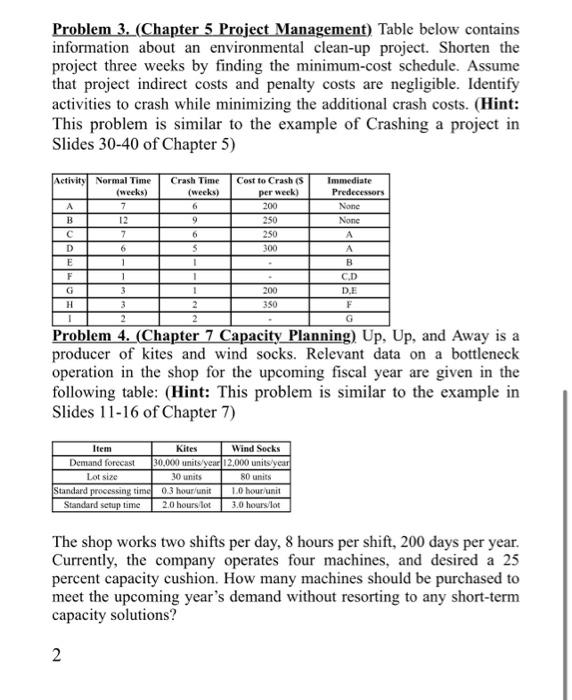

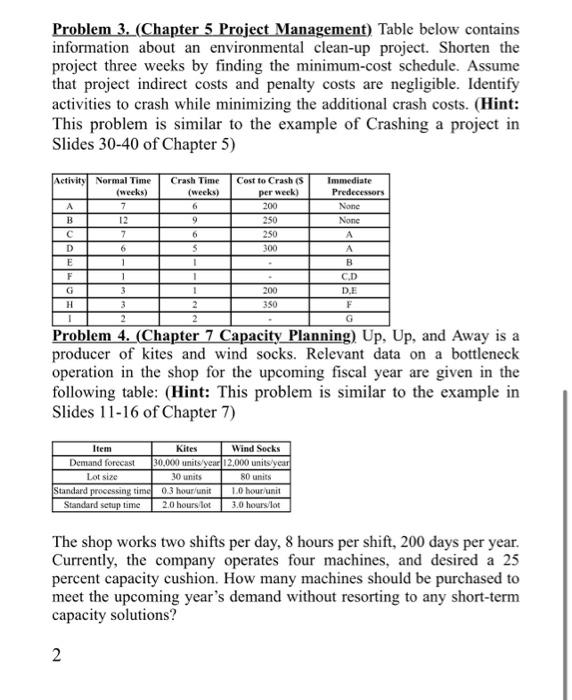

Problem 3. (Chapter 5 Project Management) Table below contains information about an environmental clean-up project. Shorten the project three weeks by finding the minimum-cost schedule. Assume that project indirect costs and penalty costs are negligible. Identify activities to crash while minimizing the additional crash costs. (Hint: This problem is similar to the example of Crashing a project in Slides 30-40 of Chapter 5) Problem 4. (Chapter 7 Capacity Planning). Up, Up, and Away is a producer of kites and wind socks. Relevant data on a bottleneck operation in the shop for the upcoming fiscal year are given in the following table: (Hint: This problem is similar to the example in Slides 11-16 of Chapter 7) The shop works two shifts per day, 8 hours per shift, 200 days per year. Currently, the company operates four machines, and desired a 25 percent capacity cushion. How many machines should be purchased to meet the upcoming year's demand without resorting to any short-term capacity solutions? Problem 3. (Chapter 5 Project Management) Table below contains information about an environmental clean-up project. Shorten the project three weeks by finding the minimum-cost schedule. Assume that project indirect costs and penalty costs are negligible. Identify activities to crash while minimizing the additional crash costs. (Hint: This problem is similar to the example of Crashing a project in Slides 30-40 of Chapter 5) Problem 4. (Chapter 7 Capacity Planning). Up, Up, and Away is a producer of kites and wind socks. Relevant data on a bottleneck operation in the shop for the upcoming fiscal year are given in the following table: (Hint: This problem is similar to the example in Slides 11-16 of Chapter 7) The shop works two shifts per day, 8 hours per shift, 200 days per year. Currently, the company operates four machines, and desired a 25 percent capacity cushion. How many machines should be purchased to meet the upcoming year's demand without resorting to any short-term capacity solutions

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started