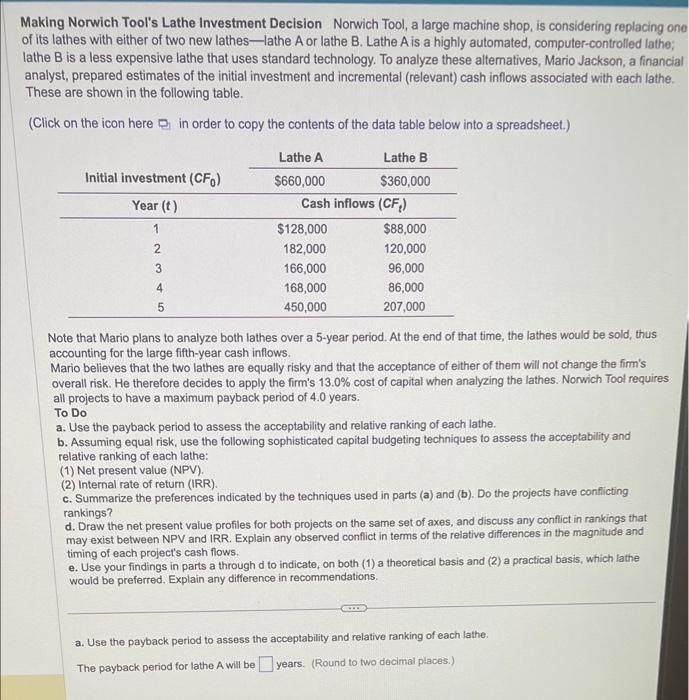

Making Norwich Tool's Lathe Investment Decision Norwich Tool, a large machine shop, is considering replacing one of its lathes with either of two new lathes - lathe A or lathe B. Lathe A is a highly automated, computer-controlled lathe; lathe B is a less expensive lathe that uses standard technology. To analyze these alternatives, Mario Jackson, a financial analyst, prepared estimates of the initial investment and incremental (relevant) cash inflows associated with each lathe. These are shown in the following table. (Click on the icon here in order to copy the contents of the data table below into a spreadsheet.) Note that Mario plans to analyze both lathes over a 5-year period. At the end of that time, the lathes would be sold, thus accounting for the large fifth-year cash inflows. Mario believes that the two lathes are equally risky and that the acceptance of either of them will not change the firm's overall risk. He therefore decides to apply the firm's 13.0% cost of capital when analyzing the lathes. Norwich Tool requires all projects to have a maximum payback period of 4.0 years. To Do a. Use the payback period to assess the acceptability and relative ranking of each lathe. b. Assuming equal risk, use the following sophisticated capital budgeting techniques to assess the acceptability and relative ranking of each lathe: (1) Net present value (NPV). (2) Internal rate of return (IRR). c. Summarize the preferences indicated by the techniques used in parts (a) and (b). Do the projects have conflicting rankings? d. Draw the net present value profiles for both projects on the same set of axes, and discuss any conflict in rankings that may exist between NPV and IRR. Explain any observed conflict in terms of the relative differences in the magnitude and timing of each project's cash flows. e. Use your findings in parts a through d to indicate, on both (1) a theoretical basis and (2) a practical basis, which lathe would be preferred. Explain any difference in recommendations. a. Use the payback period to assess the acceptability and relative ranking of each lathe. The payback period for lathe A will be years. (Round to two decimal places.)