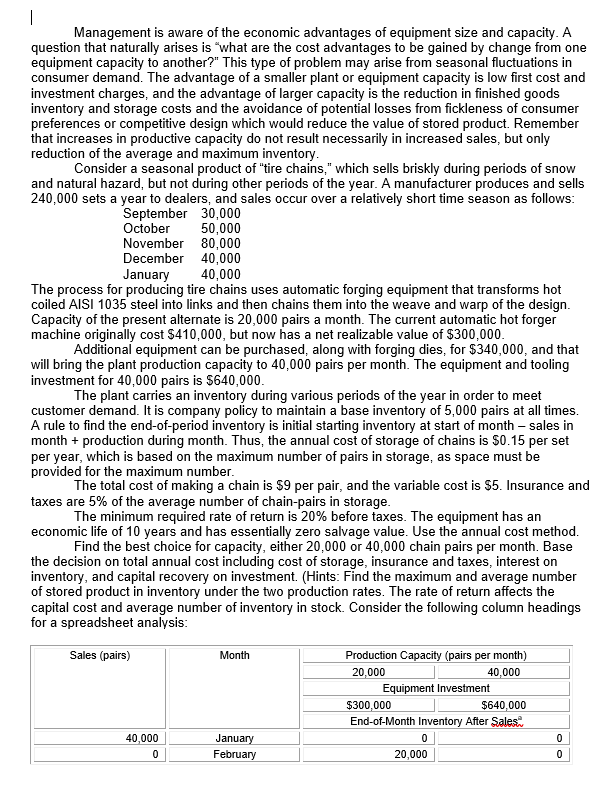

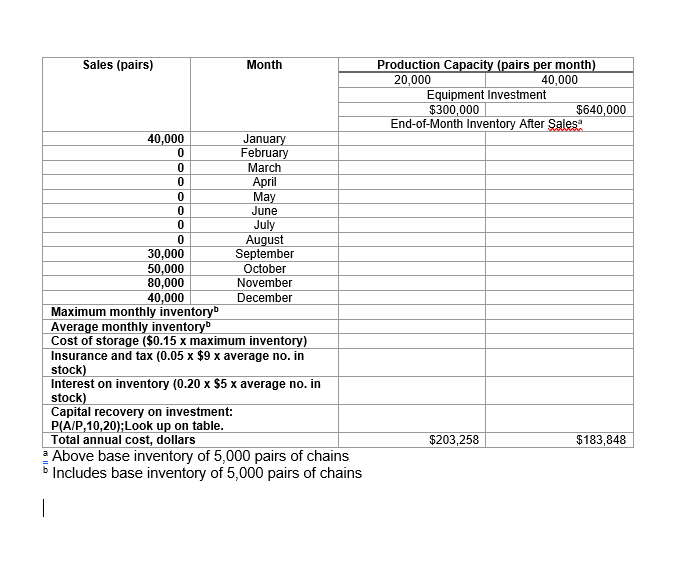

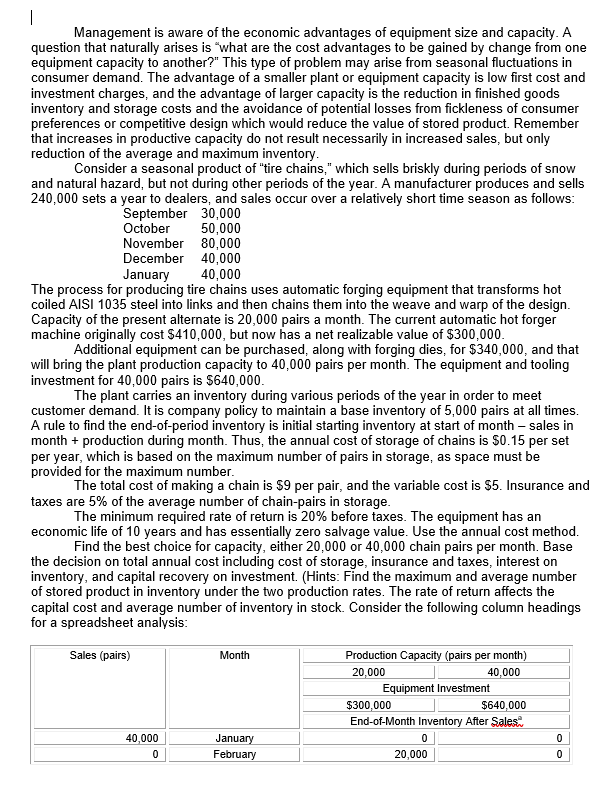

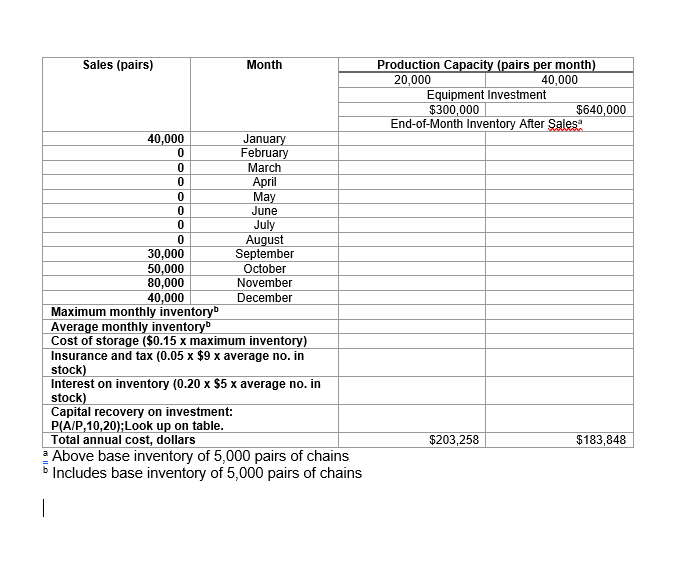

Management is aware of the economic advantages of equipment size and capacity. A question that naturally arises is "what are the cost advantages to be gained by change from one equipment capacity to another?" This type of problem may arise from seasonal fluctuations in consumer demand. The advantage of a smaller plant or equipment capacity is low first cost and investment charges, and the advantage of larger capacity is the reduction in finished goods inventory and storage costs and the avoidance of potential losses from fickleness of consumer preferences or competitive design which would reduce the value of stored product. Remember that increases in productive capacity do not result necessarily in increased sales, but only reduction of the average and maximum inventory. Consider a seasonal product of "tire chains," which sells briskly during periods of snow and natural hazard, but not during other periods of the year. A manufacturer produces and sells 240,000 sets a year to dealers, and sales occur over a relatively short time season as follows: The process for producing tire chains uses automatic forging equipment that transforms hot coiled AISI 1035 steel into links and then chains them into the weave and warp of the design. Capacity of the present alternate is 20,000 pairs a month. The current automatic hot forger machine originally cost $410,000, but now has a net realizable value of $300,000. Additional equipment can be purchased, along with forging dies, for $340,000, and that will bring the plant production capacity to 40,000 pairs per month. The equipment and tooling investment for 40,000 pairs is $640,000. The plant carries an inventory during various periods of the year in order to meet customer demand. It is company policy to maintain a base inventory of 5,000 pairs at all times. A rule to find the end-of-period inventory is initial starting inventory at start of month - sales in month + production during month. Thus, the annual cost of storage of chains is $0.15 per set per year, which is based on the maximum number of pairs in storage, as space must be provided for the maximum number. The total cost of making a chain is $9 per pair, and the variable cost is $5. Insurance and taxes are 5% of the average number of chain-pairs in storage. The minimum required rate of return is 20% before taxes. The equipment has an economic life of 10 years and has essentially zero salvage value. Use the annual cost method. Find the best choice for capacity, either 20,000 or 40,000 chain pairs per month. Base the decision on total annual cost including cost of storage, insurance and taxes, interest on inventory, and capital recovery on investment. (Hints: Find the maximum and average number of stored product in inventory under the two production rates. The rate of return affects the capital cost and average number of inventory in stock. Consider the following column headings for a spreadsheet analysis: b Includes base inventory of 5,000pairsofchain Management is aware of the economic advantages of equipment size and capacity. A question that naturally arises is "what are the cost advantages to be gained by change from one equipment capacity to another?" This type of problem may arise from seasonal fluctuations in consumer demand. The advantage of a smaller plant or equipment capacity is low first cost and investment charges, and the advantage of larger capacity is the reduction in finished goods inventory and storage costs and the avoidance of potential losses from fickleness of consumer preferences or competitive design which would reduce the value of stored product. Remember that increases in productive capacity do not result necessarily in increased sales, but only reduction of the average and maximum inventory. Consider a seasonal product of "tire chains," which sells briskly during periods of snow and natural hazard, but not during other periods of the year. A manufacturer produces and sells 240,000 sets a year to dealers, and sales occur over a relatively short time season as follows: The process for producing tire chains uses automatic forging equipment that transforms hot coiled AISI 1035 steel into links and then chains them into the weave and warp of the design. Capacity of the present alternate is 20,000 pairs a month. The current automatic hot forger machine originally cost $410,000, but now has a net realizable value of $300,000. Additional equipment can be purchased, along with forging dies, for $340,000, and that will bring the plant production capacity to 40,000 pairs per month. The equipment and tooling investment for 40,000 pairs is $640,000. The plant carries an inventory during various periods of the year in order to meet customer demand. It is company policy to maintain a base inventory of 5,000 pairs at all times. A rule to find the end-of-period inventory is initial starting inventory at start of month - sales in month + production during month. Thus, the annual cost of storage of chains is $0.15 per set per year, which is based on the maximum number of pairs in storage, as space must be provided for the maximum number. The total cost of making a chain is $9 per pair, and the variable cost is $5. Insurance and taxes are 5% of the average number of chain-pairs in storage. The minimum required rate of return is 20% before taxes. The equipment has an economic life of 10 years and has essentially zero salvage value. Use the annual cost method. Find the best choice for capacity, either 20,000 or 40,000 chain pairs per month. Base the decision on total annual cost including cost of storage, insurance and taxes, interest on inventory, and capital recovery on investment. (Hints: Find the maximum and average number of stored product in inventory under the two production rates. The rate of return affects the capital cost and average number of inventory in stock. Consider the following column headings for a spreadsheet analysis: b Includes base inventory of 5,000pairsofchain