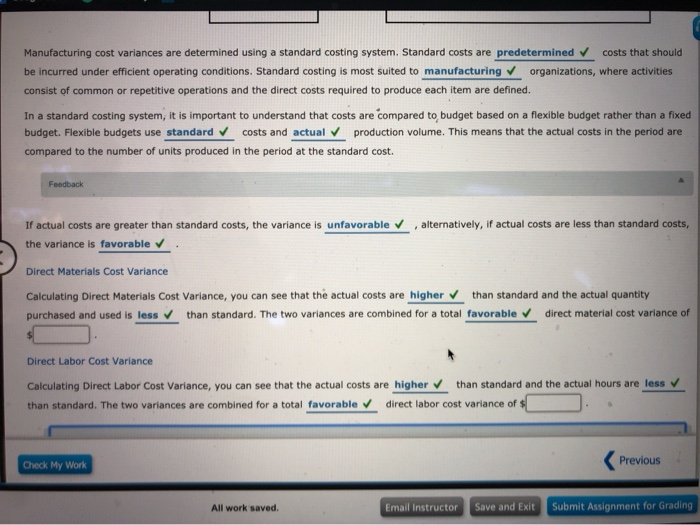

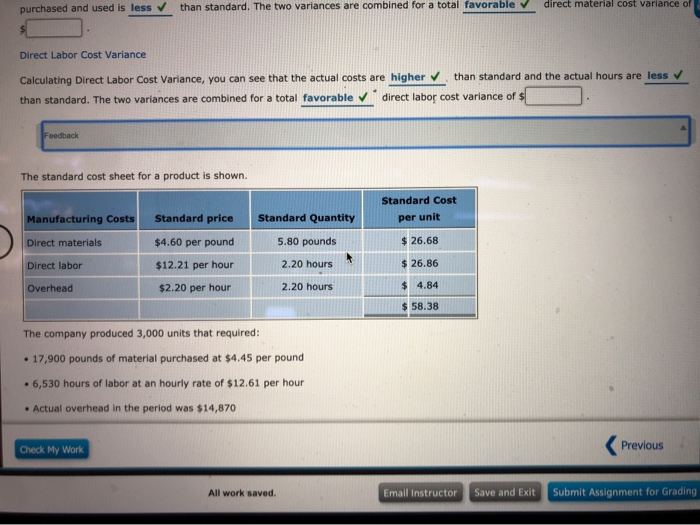

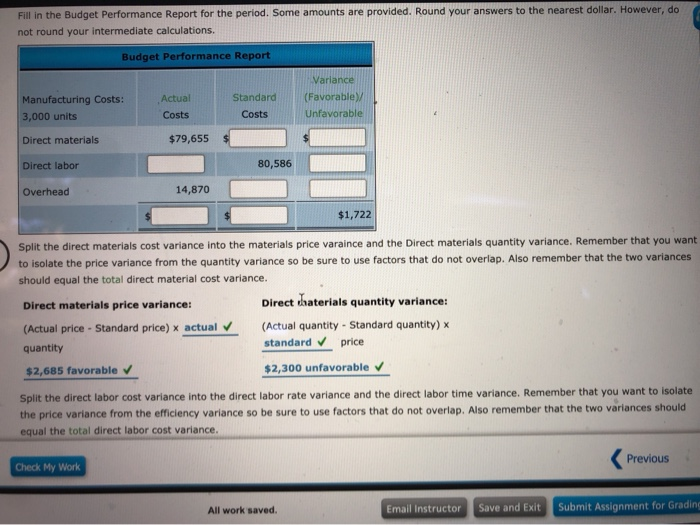

Manufacturing cost variances are determined using a standard costing system. Standard costs are predetermined costs that should be incurred under efficient operating conditions. Standard costing is most suited to manufacturing consist of common or repetitive operations and the direct costs required to produce each item are organizations, where activities defined. In a standard costing system, it is important to understand that costs are compared to budget based on a flexible budget rather than a fixed budget. Flexible budgets use standard costs and actual production volume. This means that the actual costs in the period are compared to the number of units produced in the period at the standard cost. Feedback , alternatively, if actual costs are less than standard costs, If actual costs are greater than standard costs, the variance is unfavorable the variance is favorable Direct Materials Cost Variance than standard and the actual quantity Calculating Direct Materials Cost Variance, you can see that the actual costs are higher direct material cost variance of purchased and used is less v than standard. The two variances are combined for a total favorable Direct Labor Cost Variance than standard and the actual hours are less v Calculating Direct Labor Cost Variance, you can see that the actual costs are higher direct labor cost variance of $ than standard. The two variances are combined for a total favorable Previous Check My Work Submit Assignment for Grading All work saved Email Instructor Save and Exit direct material cost variance of than standard. The two variances are combined for a total favorable purchased and used is less Direct Labor Cost Variance than standard and the actual hours are less Calculating Direct Labor Cost Variance, you can see that the actual costs are higher direct labor cost variance of $ than standard. The two variances are combined for a total favorable Feedback The standard cost sheet for a product is shown. Standard Cost Standard Quantity Standard price Manufacturing Costs per unit 5.80 pounds $26.68 $4.60 per pound Direct materials $26.86 2.20 hours $12.21 per hour Direct labor $4.84 2.20 hours $2.20 per hour Overhead 58.38 The company produced 3,000 units that required: 17,900 pounds of material purchased at $4.45 per pound 6,530 hours of labor at an hourly rate of $12.61 per hour Actual overhead in the period was $14,870 Previous Check My Work Submit Assignment for Grading Email Instructor Save and Exit All work saved. Fill in the Budget Performance Report for the period. Some amounts are provided. Round your answers to the nearest dollar. However, do not round your intermediate calculations. Budget Performance Report Varlance (Favorable)/ Standard , Actual Manufacturing Costs: Unfavorable Costs Costs 3,000 units $79,655 Direct materials 80,586 Direct labor 14,870 Overhead $1,722 Split the direct materials cost variance into the materials price varaince and the Direct materials quantity variance. Remember that you want to isolate the price variance from the quantity variance so be sure to use factors that do not overlap. Also remember that the two variances should equal the total direct material cost variance. Direct dhaterials quantity variance: Direct materials price variance: (Actual quantity - Standard quantity) x (Actual price - Standard price) x actual price standard quantity $2,300 unfavorable $2,685 favorable Split the direct labor cost variance into the direct labor rate variance and the direct labor time variance. Remember that you want to isolate the price variance from the efficiency variance so be sure to use factors that do not overlap. Also remember that the two variances should equal the total direct labor cost variance. Previous Check My Work Submit Assignment for Grading Save and Exit Email Instructor All work saved