Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Material science : please direct answers Designing a Process for Making Turbine Blades from a Nickel-based Superalloy We are tasked with designing a process for

Material science :

please direct answers

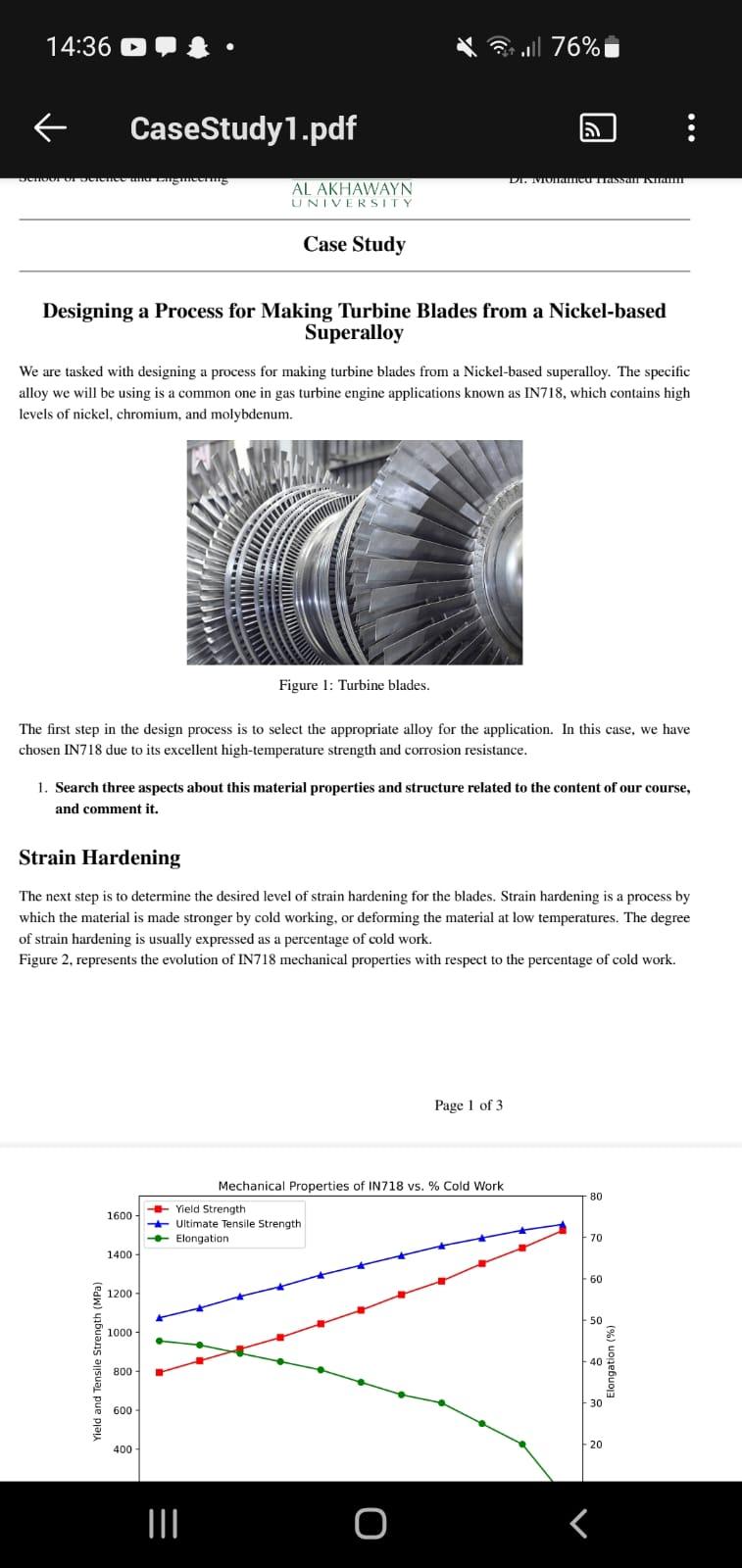

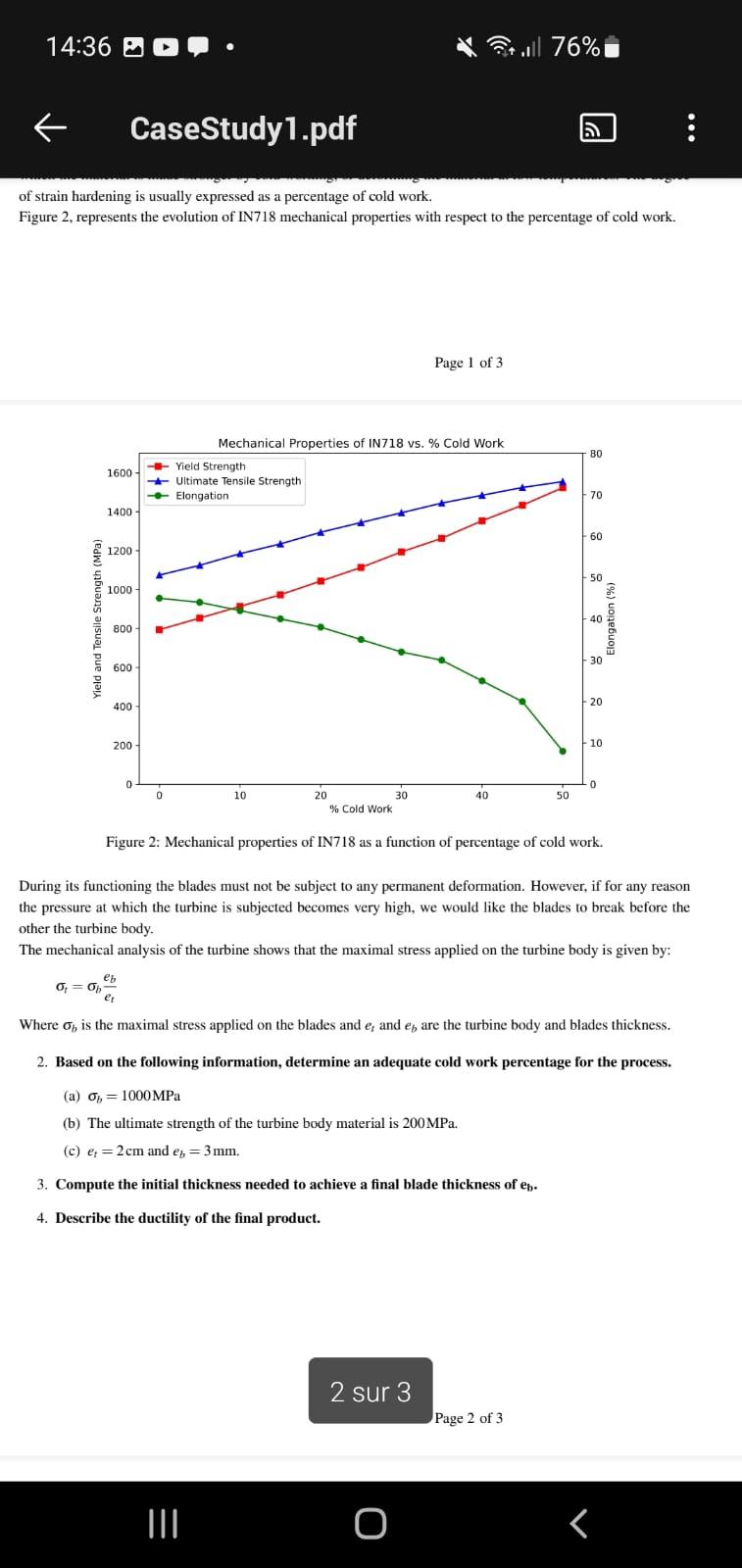

Designing a Process for Making Turbine Blades from a Nickel-based Superalloy We are tasked with designing a process for making turbine blades from a Nickel-based superalloy. The specific alloy we will be using is a common one in gas turbine engine applications known as IN718, which contains high levels of nickel, chromium, and molybdenum. rigure 1: lurdine Diades. The first step in the design process is to select the appropriate alloy for the application. In this case, we have chosen IN718 due to its excellent high-temperature strength and corrosion resistance. 1. Search three aspects about this material properties and structure related to the content of our course, and comment it. Strain Hardening The next step is to determine the desired level of strain hardening for the blades. Strain hardening is a process by which the material is made stronger by cold working, or deforming the material at low temperatures. The degree of strain hardening is usually expressed as a percentage of cold work. Figure 2, represents the evolution of IN718 mechanical properties with respect to the percentage of cold work. of strain hardening is usually expressed as a percentage of cold work. Figure 2, represents the evolution of IN718 mechanical properties with respect to the percentage of cold work. Page 1 of 3 Figure 2: Mechanical properties of IN718 as a function of percentage of cold work. During its functioning the blades must not be subject to any permanent deformation. However, if for any reason the pressure at which the turbine is subjected becomes very high, we would like the blades to break before the other the turbine body. The mechanical analysis of the turbine shows that the maximal stress applied on the turbine body is given by: t=beteb Where b is the maximal stress applied on the blades and et and eb are the turbine body and blades thickness. 2. Based on the following information, determine an adequate cold work percentage for the process. (a) b=1000MPa (b) The ultimate strength of the turbine body material is 200MPa. (c) et=2cm and eb=3mm. 3. Compute the initial thickness needed to achieve a final blade thickness of eb. 4. Describe the ductility of the final product

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started