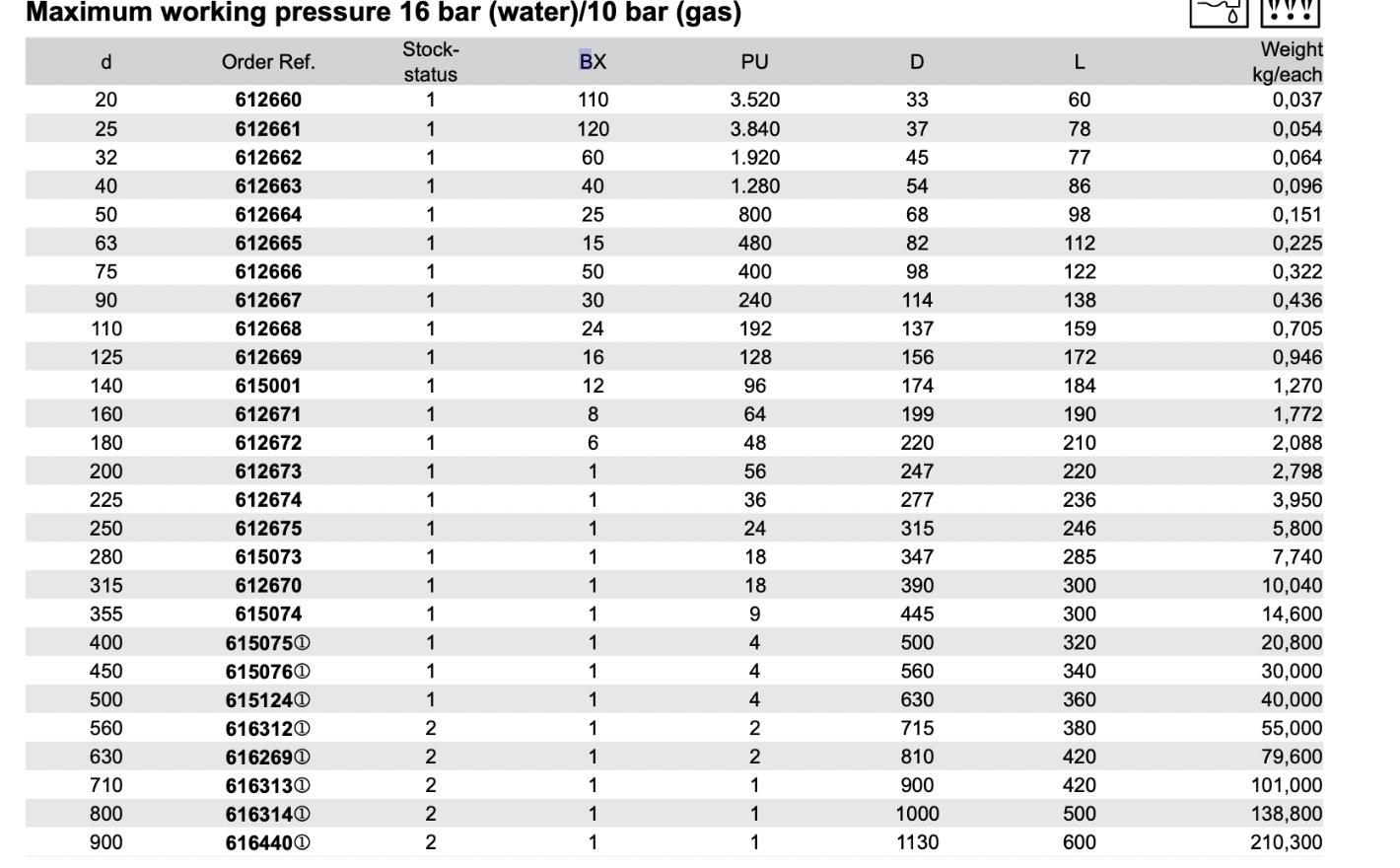

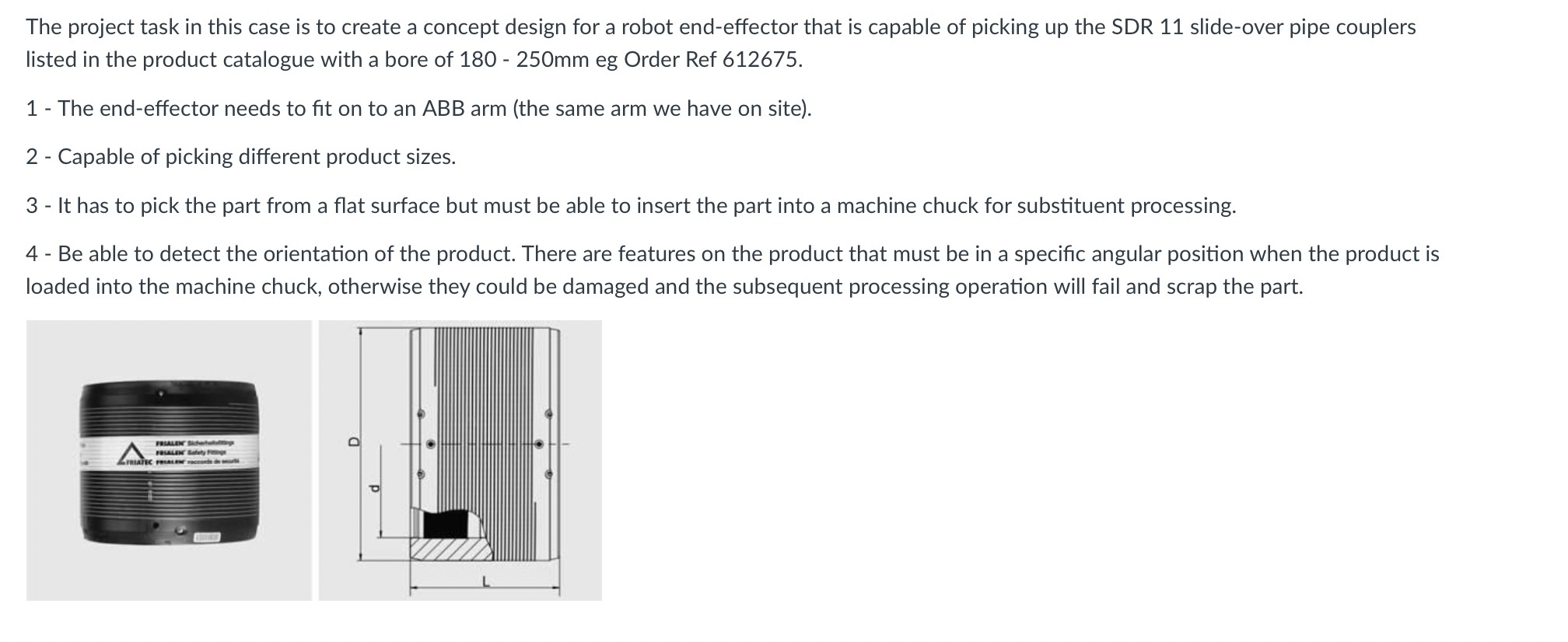

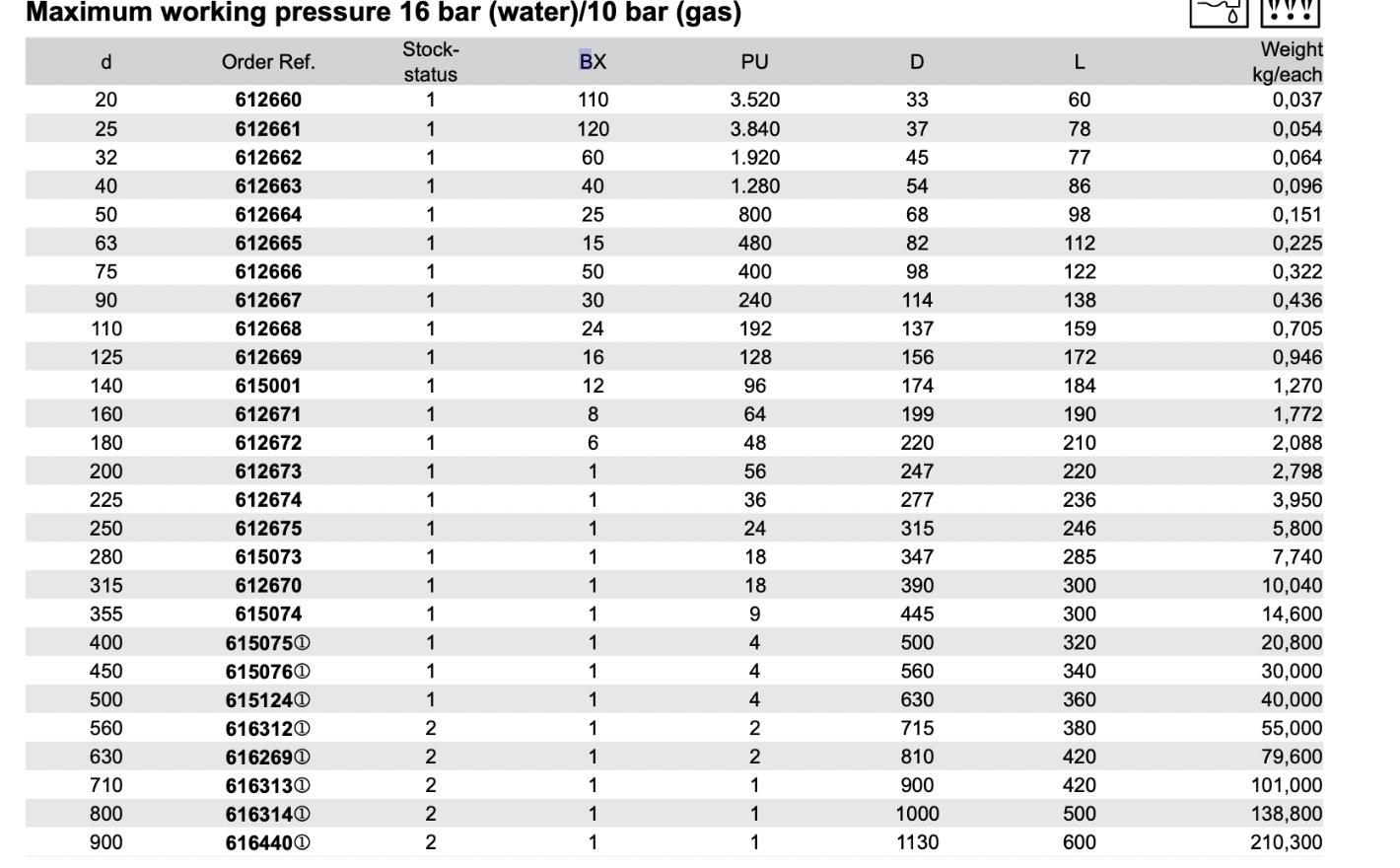

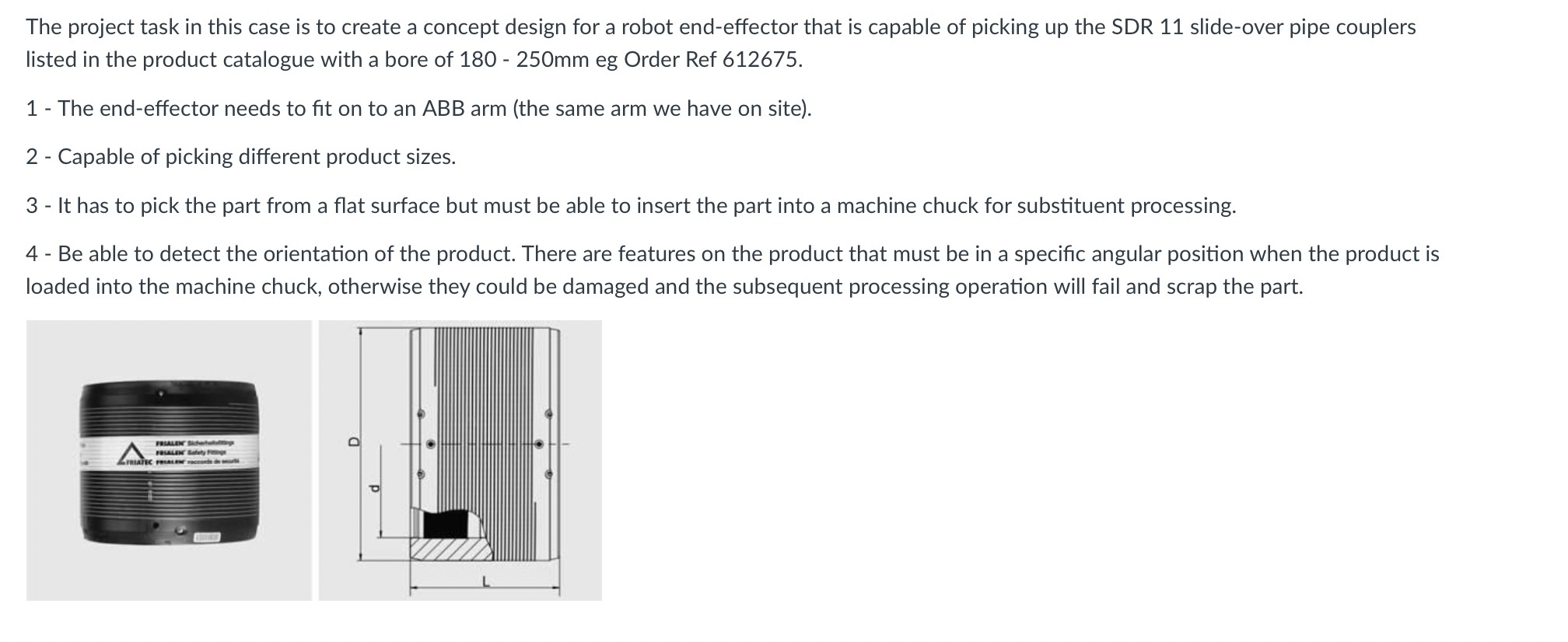

Maximum working pressure 16 bar (water)/10 bar (gas) d Order Ref. BX PU D L Stock- status 1 110 1 1 1 1 3.520 3.840 1.920 1.280 800 480 400 240 192 128 120 60 40 25 15 50 30 24 16 12 1 1 1 1 1 1 96 64 8 1 1 20 25 32 40 50 63 75 90 110 125 140 160 180 200 225 250 280 315 355 400 450 500 560 630 710 800 900 612660 612661 612662 612663 612664 612665 612666 612667 612668 612669 615001 612671 612672 612673 612674 612675 615073 612670 615074 6150750 6150760 6151240 6163120 6162690 6163130 6163140 6164400 6 1 1 1 33 37 45 54 68 82 98 114 137 156 174 199 220 247 277 315 347 390 445 500 560 630 715 810 900 1000 1130 48 56 36 24 18 Weight kg/each 0,037 0,054 0,064 0,096 0,151 0,225 0,322 0,436 0,705 0,946 1,270 1,772 2,088 2,798 3,950 5,800 7,740 10,040 14,600 20,800 30,000 40,000 55,000 79,600 101,000 138,800 210,300 60 78 77 86 98 112 122 138 159 172 184 190 210 220 236 246 285 300 300 320 340 360 380 420 420 500 600 1 1 1 1 1 1 1 18 1 1 9 4 1 1 1 4 1 1 1 4 2 1 2 2 1 2 1 NNN 1 1 1 1 1 The project task in this case is to create a concept design for a robot end-effector that is capable of picking up the SDR 11 slide-over pipe couplers listed in the product catalogue with a bore of 180 - 250mm eg Order Ref 612675. 1 - The end-effector needs to fit on to an ABB arm (the same arm we have on site). 2 - Capable of picking different product sizes. 3 - It has to pick the part from a flat surface but must be able to insert the part into a machine chuck for substituent processing. 4 - Be able to detect the orientation of the product. There are features on the product that must be in a specific angular position when the product is loaded into the machine chuck, otherwise they could be damaged and the subsequent processing operation will fail and scrap the part. FRILENS FALEN AIATEC FALEN M Maximum working pressure 16 bar (water)/10 bar (gas) d Order Ref. BX PU D L Stock- status 1 110 1 1 1 1 3.520 3.840 1.920 1.280 800 480 400 240 192 128 120 60 40 25 15 50 30 24 16 12 1 1 1 1 1 1 96 64 8 1 1 20 25 32 40 50 63 75 90 110 125 140 160 180 200 225 250 280 315 355 400 450 500 560 630 710 800 900 612660 612661 612662 612663 612664 612665 612666 612667 612668 612669 615001 612671 612672 612673 612674 612675 615073 612670 615074 6150750 6150760 6151240 6163120 6162690 6163130 6163140 6164400 6 1 1 1 33 37 45 54 68 82 98 114 137 156 174 199 220 247 277 315 347 390 445 500 560 630 715 810 900 1000 1130 48 56 36 24 18 Weight kg/each 0,037 0,054 0,064 0,096 0,151 0,225 0,322 0,436 0,705 0,946 1,270 1,772 2,088 2,798 3,950 5,800 7,740 10,040 14,600 20,800 30,000 40,000 55,000 79,600 101,000 138,800 210,300 60 78 77 86 98 112 122 138 159 172 184 190 210 220 236 246 285 300 300 320 340 360 380 420 420 500 600 1 1 1 1 1 1 1 18 1 1 9 4 1 1 1 4 1 1 1 4 2 1 2 2 1 2 1 NNN 1 1 1 1 1 The project task in this case is to create a concept design for a robot end-effector that is capable of picking up the SDR 11 slide-over pipe couplers listed in the product catalogue with a bore of 180 - 250mm eg Order Ref 612675. 1 - The end-effector needs to fit on to an ABB arm (the same arm we have on site). 2 - Capable of picking different product sizes. 3 - It has to pick the part from a flat surface but must be able to insert the part into a machine chuck for substituent processing. 4 - Be able to detect the orientation of the product. There are features on the product that must be in a specific angular position when the product is loaded into the machine chuck, otherwise they could be damaged and the subsequent processing operation will fail and scrap the part. FRILENS FALEN AIATEC FALEN M