Answered step by step

Verified Expert Solution

Question

1 Approved Answer

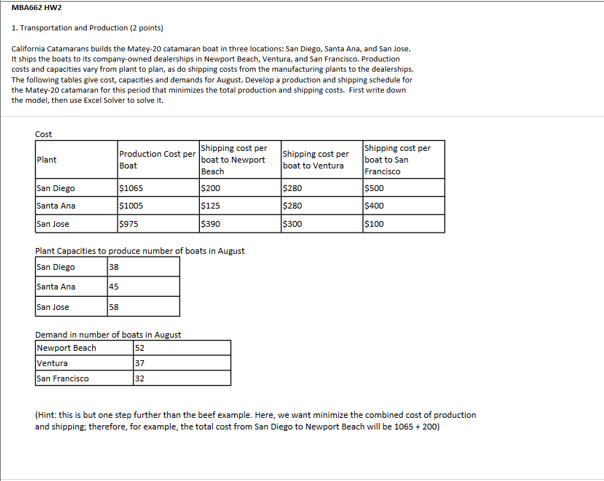

MBA662 HW2 1. Transportation and Production (2 points) California Catamarans builds the Matey-20 catamaran boat in three locations: San Diego, Santa Ana, and San

MBA662 HW2 1. Transportation and Production (2 points) California Catamarans builds the Matey-20 catamaran boat in three locations: San Diego, Santa Ana, and San Jose. It ships the boats to its company-owned dealerships in Newport Beach, Ventura, and San Francisco. Production costs and capacities vary from plant to plan, as do shipping costs from the manufacturing plants to the dealerships. The following tables give cost, capacities and demands for August. Develop a production and shipping schedule for the Matey-20 catamaran for this period that minimizes the total production and shipping costs. First write down the model, then use Excel Solver to solve it. Cost Plant San Diego Santa Ana San Jose Production Cost per Boat $1065 $1005 $975 Shipping cost per boat to Newport Beach $200 $125 $390 Plant Capacities to produce number of boats in August San Diego 38 Santa Ana 45 San Jose 58 Demand in number of boats in August Newport Beach 52 Ventura 37 San Francisco 32 Shipping cost per boat to Ventura $280 $280 $300 Shipping cost per boat to San Francisco $500 $400 $100 (Hint: this is but one step further than the beef example. Here, we want minimize the combined cost of production and shipping; therefore, for example, the total cost from San Diego to Newport Beach will be 1065 +200) MBA662 HW2 1. Transportation and Production (2 points) California Catamarans builds the Matey-20 catamaran boat in three locations: San Diego, Santa Ana, and San Jose. It ships the boats to its company-owned dealerships in Newport Beach, Ventura, and San Francisco. Production costs and capacities vary from plant to plan, as do shipping costs from the manufacturing plants to the dealerships. The following tables give cost, capacities and demands for August. Develop a production and shipping schedule for the Matey-20 catamaran for this period that minimizes the total production and shipping costs. First write down the model, then use Excel Solver to solve it. Cost Plant San Diego Santa Ana San Jose Production Cost per Boat $1065 $1005 $975 Shipping cost per boat to Newport Beach $200 $125 $390 Plant Capacities to produce number of boats in August San Diego 38 Santa Ana 45 San Jose 58 Demand in number of boats in August Newport Beach 52 Ventura 37 San Francisco 32 Shipping cost per boat to Ventura $280 $280 $300 Shipping cost per boat to San Francisco $500 $400 $100 (Hint: this is but one step further than the beef example. Here, we want minimize the combined cost of production and shipping; therefore, for example, the total cost from San Diego to Newport Beach will be 1065 +200)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

This problem can be formulated as a linear programming problem to minimize the total cost of product...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started