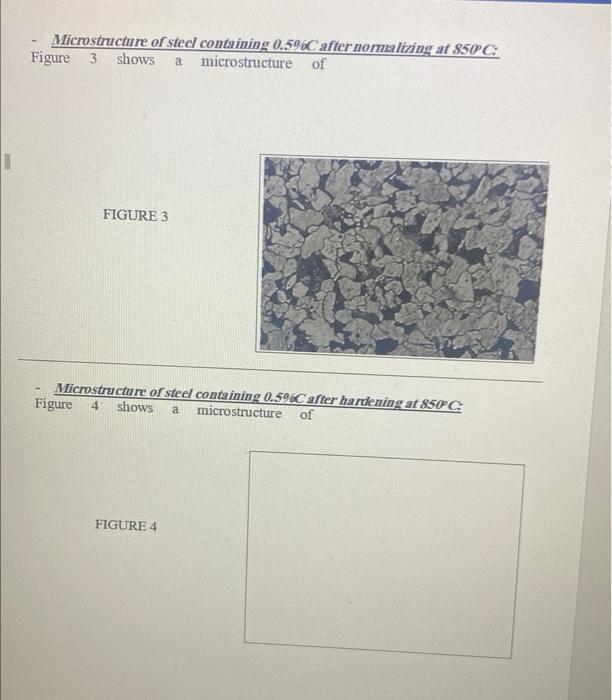

- Microstructure of steel containing 0.50 Cafternormalining at 850C : Figure 3 shows a microstructure of FIGURE 3 1. Equipments: 1. Muffle furnace 2. Grinding and polishing machine. 3- Reflected light microscope 4- Air compressor 2. Materials 1. Four identical specimens of steel containing 0.5%C 2. SiC emery papers, with 150,320,400,600,800, and 1200 grit size. 3- Diamond paste + polishing clothing. 4. 3\% nital ( 97% Methyl Alcohol + 3% Nitric Acid) solution for etching. 3. Experimental procedure 1- An annealed specimen was cooled in the furnace from austenite region at 850C. 2- A normalized specimen was cooled in air from austenite region at 850C, so cooling rate increases. 3- A hardened specimen was quenched in water from austenite region at 850C. 4. Take the heat-treated (annealed, normalized, hardened) specimens. 5- Polish the specimens by using (80,120,240,400,600) grade emery papers. 6- Subject the given specimens to mirror like finish by using disc polishing machine. 7- Clean the specimens with alcohol and wash it under the stream of flowing water. 8- After washing, the specimens are dried. 9. After drying, supply the suitable etching agent for 10 to 30sec. 10. After etching, wash the specimens under stream of flowing water. 11- Dry the specimens with the help air drier. 12. Place the specimens for metallurgical studies. 13. Draw the microstructures and analyze the properties. - Microstructure of steel containing 0.50 Cafternormalining at 850C : Figure 3 shows a microstructure of FIGURE 3 1. Equipments: 1. Muffle furnace 2. Grinding and polishing machine. 3- Reflected light microscope 4- Air compressor 2. Materials 1. Four identical specimens of steel containing 0.5%C 2. SiC emery papers, with 150,320,400,600,800, and 1200 grit size. 3- Diamond paste + polishing clothing. 4. 3\% nital ( 97% Methyl Alcohol + 3% Nitric Acid) solution for etching. 3. Experimental procedure 1- An annealed specimen was cooled in the furnace from austenite region at 850C. 2- A normalized specimen was cooled in air from austenite region at 850C, so cooling rate increases. 3- A hardened specimen was quenched in water from austenite region at 850C. 4. Take the heat-treated (annealed, normalized, hardened) specimens. 5- Polish the specimens by using (80,120,240,400,600) grade emery papers. 6- Subject the given specimens to mirror like finish by using disc polishing machine. 7- Clean the specimens with alcohol and wash it under the stream of flowing water. 8- After washing, the specimens are dried. 9. After drying, supply the suitable etching agent for 10 to 30sec. 10. After etching, wash the specimens under stream of flowing water. 11- Dry the specimens with the help air drier. 12. Place the specimens for metallurgical studies. 13. Draw the microstructures and analyze the properties