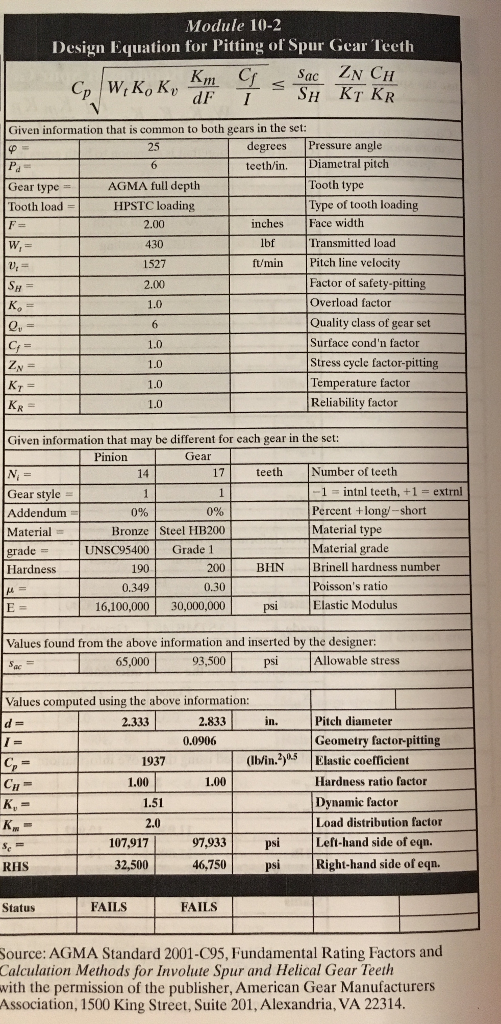

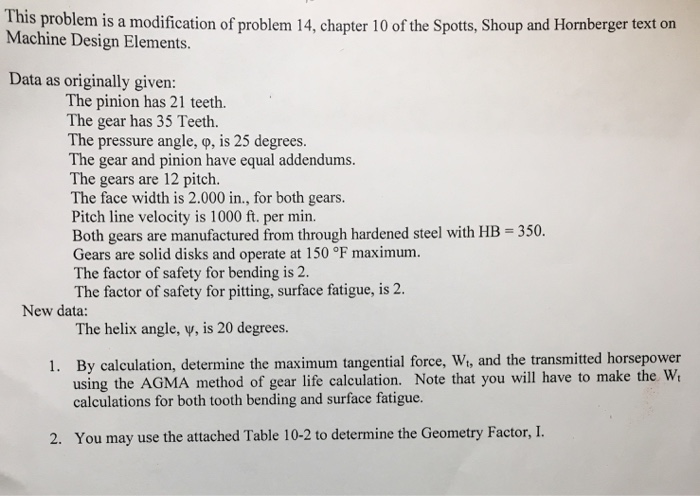

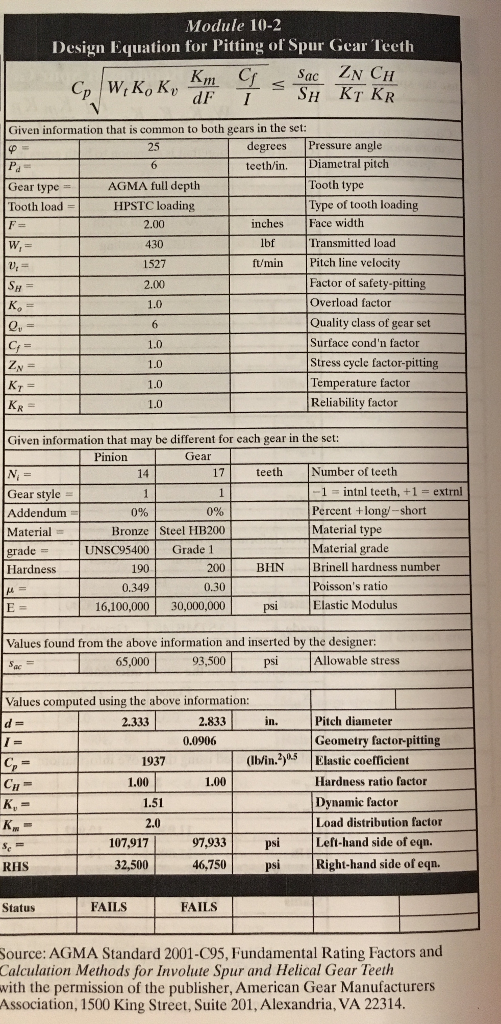

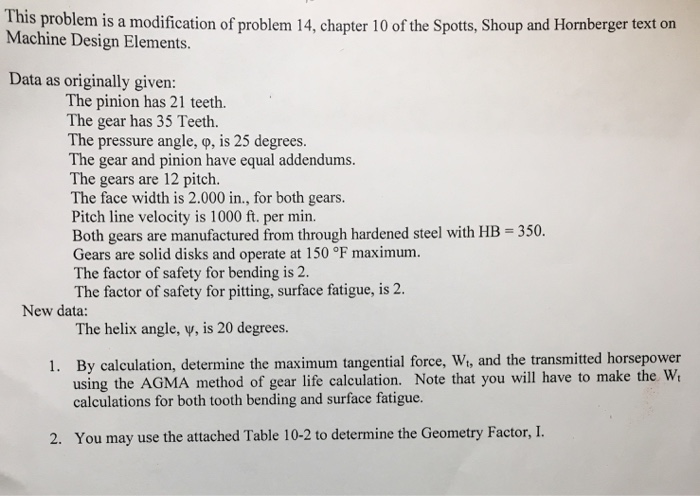

Module 10-2 Design Equation for Pitting of Spur Gear Teeth Km C dF I SH KT KR Given information that is common to both gears in the set: degrees Pressure angle teeth/in. Diametral pitch Tooth type Type of tooth loading AGMA full depth HPSTC loading 2.00 430 1527 Gear type Tooth load inches Face width lbf Iransmitted load ft/min Pitch line velocity Factor of safety-pitting Overload factor Quality class of gear set Surface cond'n factor Stress cycle factor-pitting Temperature factor Reliability factor 1.0 Cf 1.0 Given information that may be different for each gear in the set: Pinion Gear 14 17 teeth Number of teeth Gear style Addendunm Material grade- Hardness intnl teeth, +1-extrnl Percent +long-shont Material type Material grade 0% Bronze |Steel HB200 UNSC95400 Grade 1 BHNBrinell hardness number 200 0.30 16,100,000 30,000,000 190 Poisson's ratio Elastic Modulus 0.349 Values found from the above information and inserted by the designer 65,000 93,500 psi Allowable stress Values computed using the above information: 2.333 Pitch diameter 2.833 0.0906 n. Geometry factor-pitting 1937 (Ibin. Elastic coefficient 1.00 Hardness ratio factor Dynamic factor Load distribution factor Left-hand side of eqrn. CH 1.00 1.51 2.0 107,9177 97,933psi 46,750 RHS 32,500 psi Right-hand side of eqn. Status FAILS FAILS Source: AGMA Standard 2001-C95, Fundamental Rating Factors and Calculation Methods for Involute Spur and Helical Gear Teeth with the permission of the publisher, American Gear Manufacturers Association, 1500 King Street, Suite 201, Alexandria, VA 22314 Module 10-2 Design Equation for Pitting of Spur Gear Teeth Km C dF I SH KT KR Given information that is common to both gears in the set: degrees Pressure angle teeth/in. Diametral pitch Tooth type Type of tooth loading AGMA full depth HPSTC loading 2.00 430 1527 Gear type Tooth load inches Face width lbf Iransmitted load ft/min Pitch line velocity Factor of safety-pitting Overload factor Quality class of gear set Surface cond'n factor Stress cycle factor-pitting Temperature factor Reliability factor 1.0 Cf 1.0 Given information that may be different for each gear in the set: Pinion Gear 14 17 teeth Number of teeth Gear style Addendunm Material grade- Hardness intnl teeth, +1-extrnl Percent +long-shont Material type Material grade 0% Bronze |Steel HB200 UNSC95400 Grade 1 BHNBrinell hardness number 200 0.30 16,100,000 30,000,000 190 Poisson's ratio Elastic Modulus 0.349 Values found from the above information and inserted by the designer 65,000 93,500 psi Allowable stress Values computed using the above information: 2.333 Pitch diameter 2.833 0.0906 n. Geometry factor-pitting 1937 (Ibin. Elastic coefficient 1.00 Hardness ratio factor Dynamic factor Load distribution factor Left-hand side of eqrn. CH 1.00 1.51 2.0 107,9177 97,933psi 46,750 RHS 32,500 psi Right-hand side of eqn. Status FAILS FAILS Source: AGMA Standard 2001-C95, Fundamental Rating Factors and Calculation Methods for Involute Spur and Helical Gear Teeth with the permission of the publisher, American Gear Manufacturers Association, 1500 King Street, Suite 201, Alexandria, VA 22314