Question: Monte Carlo analysis is a mathematical simulation of physical processes based on ones knowledge of the distributions of the process parameters. Monte Carlo simulations are

Monte Carlo analysis is a mathematical simulation of physical processes based on ones knowledge of the distributions of the process parameters. Monte Carlo simulations are used to predict the performance of complex physical systems that are subject to uncertainty and whose outcomes are controlled by the interaction of multiple independent factors.

A three-component system, shown below, consists of a top plate, a base plate, and a bolt that must fit through holes in the two plates simultaneously. The top plate is not free to move relative to the base plate. Since there is variation in the diameters of the holes and bolt and in the true positions of the holes due to manufacturing and/or assembly tolerances, there will be some chance that the alignment will be off enough that the bolt will not fit through the two holes.

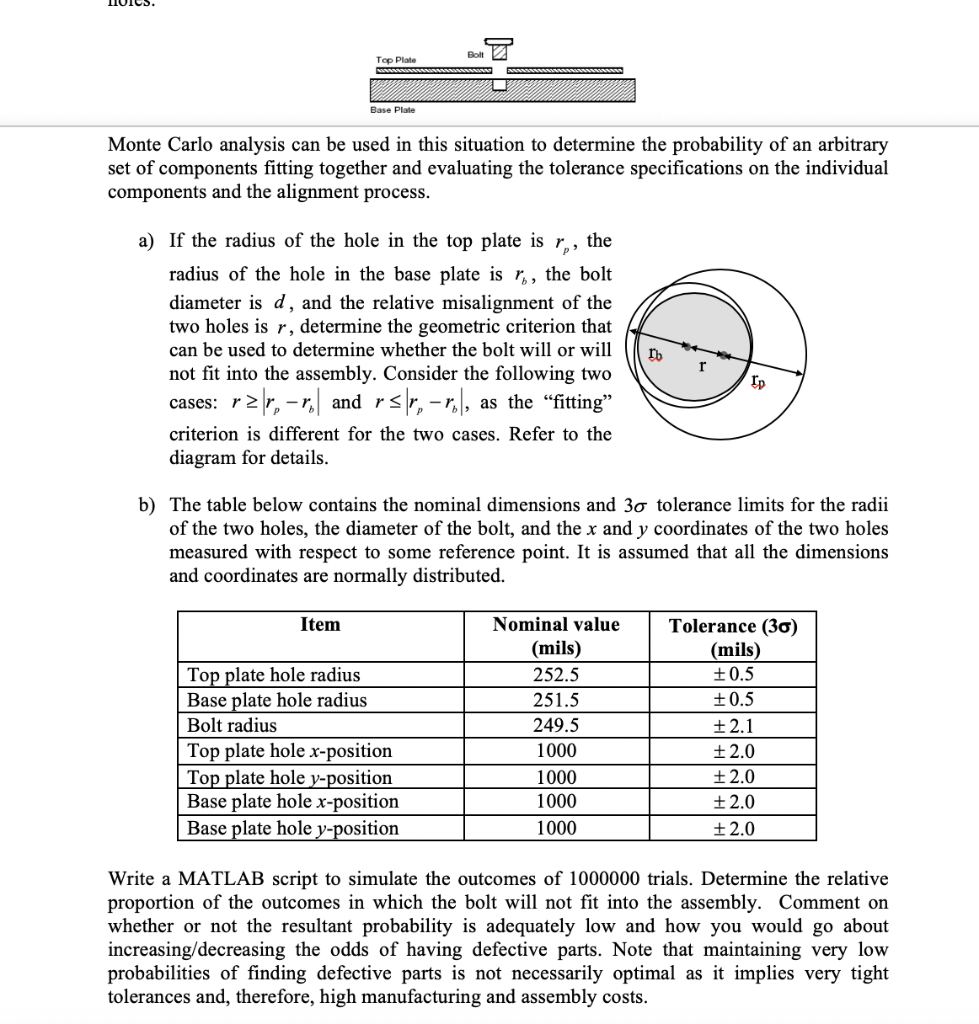

Bolt Top Plate Base Plate Monte Carlo analysis can be used in this situation to determine the probability of an arbitrary set of components fitting together and evaluating the tolerance specifications on the individual components and the alignment process. a) If the radius of the hole in the top plate is ry, the radius of the hole in the base plate is ry, the bolt diameter is d, and the relative misalignment of the two holes is r, determine the geometric criterion that can be used to determine whether the bolt will or will not fit into the assembly. Consider the following two cases: r2\", -ral and rs|r, -rol, as the fitting criterion is different for the two cases. Refer to the diagram for details. Ib r b) The table below contains the nominal dimensions and 30 tolerance limits for the radii of the two holes, the diameter of the bolt, and the x and y coordinates of the two holes measured with respect to some reference point. It is assumed that all the dimensions and coordinates are normally distributed. Item Top plate hole radius Base plate hole radius Bolt radius Top plate hole x-position Top plate hole y-position Base plate hole x-position Base plate hole y-position Nominal value (mils) 252.5 251.5 249.5 1000 1000 1000 1000 Tolerance (30) (mils) +0.5 +0.5 +2.1 + 2.0 + 2.0 + 2.0 +2.0 Write a MATLAB script to simulate the outcomes of 1000000 trials. Determine the relative proportion of the outcomes in which the bolt will not fit into the assembly. Comment on whether or not the resultant probability is adequately low and how you would go about increasing/decreasing the odds of having defective parts. Note that maintaining very low probabilities of finding defective parts is not necessarily optimal as it implies very tight tolerances and, therefore, high manufacturing and assembly costs. Bolt Top Plate Base Plate Monte Carlo analysis can be used in this situation to determine the probability of an arbitrary set of components fitting together and evaluating the tolerance specifications on the individual components and the alignment process. a) If the radius of the hole in the top plate is ry, the radius of the hole in the base plate is ry, the bolt diameter is d, and the relative misalignment of the two holes is r, determine the geometric criterion that can be used to determine whether the bolt will or will not fit into the assembly. Consider the following two cases: r2\", -ral and rs|r, -rol, as the fitting criterion is different for the two cases. Refer to the diagram for details. Ib r b) The table below contains the nominal dimensions and 30 tolerance limits for the radii of the two holes, the diameter of the bolt, and the x and y coordinates of the two holes measured with respect to some reference point. It is assumed that all the dimensions and coordinates are normally distributed. Item Top plate hole radius Base plate hole radius Bolt radius Top plate hole x-position Top plate hole y-position Base plate hole x-position Base plate hole y-position Nominal value (mils) 252.5 251.5 249.5 1000 1000 1000 1000 Tolerance (30) (mils) +0.5 +0.5 +2.1 + 2.0 + 2.0 + 2.0 +2.0 Write a MATLAB script to simulate the outcomes of 1000000 trials. Determine the relative proportion of the outcomes in which the bolt will not fit into the assembly. Comment on whether or not the resultant probability is adequately low and how you would go about increasing/decreasing the odds of having defective parts. Note that maintaining very low probabilities of finding defective parts is not necessarily optimal as it implies very tight tolerances and, therefore, high manufacturing and assembly costs